This is the second part of a two-series article on the most popular 3D printing filaments in which we will analyze such building materials as nylon, PET, PVA/HIPS. Last week we started analyzing general and technical properties of most commonly used filaments for home-based 3D printers, such as ABS and PLA filaments.

As we’ve already mentioned, ABS and PLA are the most widely used 3D filaments, thanks to their accessibility of price and ease of use and handling during the printing process. PLA also come in multiple colors and is available in several special effect blends, which make it more appealing for hobbyists, who envision printing different fun stuff. There are several interesting ABS-based blends, however fewer than PLA-based. Nevertheless, the blends are also widely used to print interesting items, or even more durable than with the standard ABS.

Nylon (Polyamide)

Nylon is a synthetic polymer with silky structure, which can be processed by melting technique into various shapes, films and fiber.

Nylon printed models have somehow a rough surface, but they can be polished to a certain smoother degree, although this material is not recommended for models with tiny details, as it smoothing method can damage them.

Nylon properties:

- General printing temperature: between 245° and 300°;

- Physical properties: highly durable, highly strong;

- Flexibility: highly flexible;

- Available colors: small variety of colors. Mostly, nylon is available in translucent to almost white color, but it can be colored with acid-based dye;

- Price: cheap;

- Eco-friendliness: biodegradable, although it takes from 30 to 40 years;

- Odor: odorless, although it releases toxic fumes at high temperatures.

Nylon is a material that is less prone to warp and less brittle than PLA and ABS, which makes it a perfect thermoplastic for hobbyist 3D printing. It is recommended a 50° to 100° heated bed, though, to ensure that the layers stick together while slowly cooling.

Nylon 3D printed models have somehow a rough surface, but they can be polished to a certain smoother degree, although this material is not recommended for models with tiny details, as it smoothing method can damage them.

There is however several drawbacks, such as the inability to adhere to mirror-like heated bed. In order to make the adherence possible, it is advised to use PVA based glue on the surface prior to starting your 3D printing process.

To avoid warping in your nylon printed item, don’t use layer cooling fans and avoid cool rooms for best results

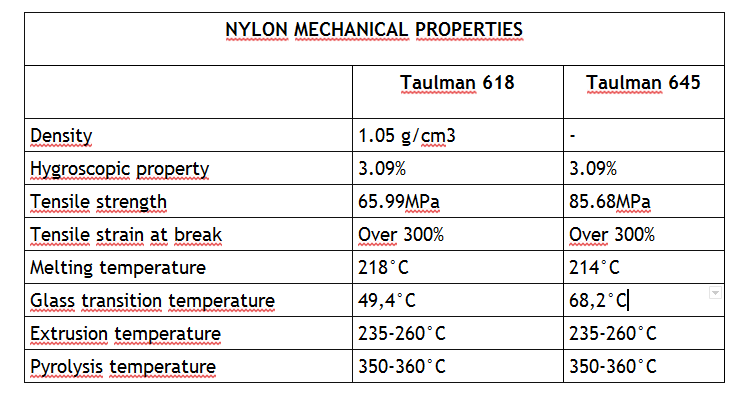

The most popular nylon 3D printing filaments are those manufactured by Taulman and Stratasys companies, and namely: Taulman 618, Taulman 645, and Bridge Nylon.

Taulman 618 has excellent surface bonding, which means that it does not require heated bed, it has reduced water absorption and is tear resistant. It has a natural to white color, but it can be colored with any fabric dye. This particular material is known to have very high inter-layer bonding properties. This means that the printed model will be very strong and resistant from delimitation. Also, Taulman 618 nylon does not releases any fumes during printing.

Taulman 645 has a clear color, but it is considered a difficult material to work with. Due to its transparency, the model can be inspected with the naked eye to determine the adhesion of inner layers.

Taulman 645 3D printing filament is more durable than Taulman 618 and more stress-resistant. It is also 20% less pliable and less prone to warping. It was developed as a result of responses to Taulman 618 filament of the industry community, which was looking for a stronger nylon.

Bridge Nylon

The name comes from the combination of strength of Nylon 645 and the price of ABS and PLA thermoplastics. For glass heated bed adhesion it also requires a coat of glue stick. The most common problem with all other nylons is that they absorb moisture, which interferes with the printing process and affects the quality of the printed item. Bridge nylon has overcome this problem and it is said that does not absorb moisture from air. It is also more durable and it allows an easy 3D printing experience.

Credits to taulman3d.com

Nylon 3D filament storage

As mentioned before, nylon filaments are prone to absorb moisture from the air, which can be problematic during printing. It is the moisture that the filament absorbs that produces fumes during printing. That is why, it is recommended to store nylon 3D printing filaments appropriately and correctly, to prolong their shelf life and to ensure that the nylon-printed item is of good quality.

Nylon filaments need to be stored in dry and airtight containers, with silica gel pads. Also, it is advised to dry the nylon filament prior to its use, with desiccant, vacuum, or using elevated temperature.

Read this: The Main Trends in 3D Printing Technology to Look for in 2016

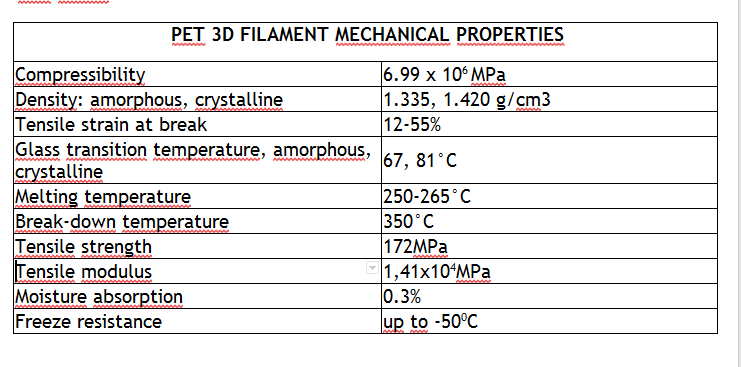

3D Printing Filament: PET (PolyEthylene Terephthalate)

PET is a flexible and strong 3D printer filament, with printing requirements similar to PLA. It is a better solution than ABS filaments in matter of strength and flexibility also. Due to its physical properties, PET filament found its use in printing phone cases, robotics and wearable technology. PET has perfect layer bonding and the 3D printed items are resistant to shock and impact. It has a glossy finish and can be printed without a heated bed. It doesn’t releases odors or fumes.

PET 3D filament properties:

- General printing temperature: between 212° and 224°;

- Physical properties: strong and lightweight, highly durable;

- Flexibility: flexible;

- Available colors: dozens of colors;

- Price: expensive;

- Eco-friendliness: 100% recyclable;

- Odor: odorless.

PVA 3D Printer Filament

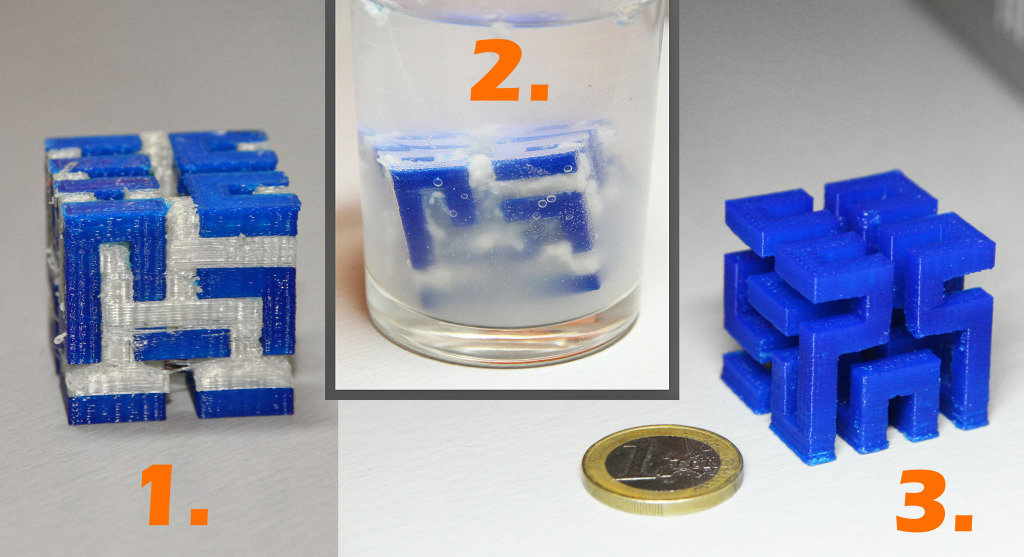

PVA (Polyvinyl Acetate) is a filament used mostly as a support material because of its translucent color. It is also soluble in lukewarm water, which also makes it a perfect support material. PVA is used in printers with two extruders, where one extrudes PLA or ABS, and the other extrudes PVA as a support for the item with overhang features. Therefore, PVA is the ideal material for models with a lot of overhang features as it provides support and avoids collapse or warp of the object. Due to its solvability in water, it should be kept away from moisture prior to printing.

PVA Filament is mostly used as a support material because of its translucent color an solubility in lukewarm water.

PVA 3D Filament Properties:

- General printing temperature: between 180° and 230°;

- Physical properties: good durability;

- Flexibility: low flexibility, some bending;

- Available colors: natural color only;

- Price: expensive;

- Eco-friendliness: non-toxic;

- Odor: slight odor.

PVA Filament Storage:

It is recommended to store the PVA filaments in an airtight box or container and to dry it before using it.

HIPS 3D Printing Filaments

HIPS (High Impact Polystyrene) is another great option as a support material in 3D printing with ABS in a printer with two extrusions. HIPS is soluble in Limonene. Therefore, it is easily removed with Limonene solution, leaving the final model clean from any overhang structures. This means that you will no longer need to cut, scrape or use any other method to clean your 3D printed model, thus avoiding its damage.

HIPS is ideal to be printed with ABS, because the two build materials have similar features.

HIPS 3D Filament properties:

- General printing temperature: between 210° and 250°

- Physical properties: high durability

- Flexibility: low flexibility, minor bending

- Available colors: moderate variety

- Price: expensive

- Eco-friendliness: recyclable

HIPS 3D Filament leaves your model clean, as all residues are easily removed with Limonene solution.

Credits to 3Dinspires.com

HIPS Filament storage

HIPS filaments are also known to absorb water from air. Therefore, as most of 3D filaments for 3D printing, they require special handling and storage. An airtight container or box is a good option to keep your filament away from the moisture in the air.

BoTTOm Line

Having analyzed the most commonly used nylon, PET, PVA/HIPS 3D printing filaments you now have a general picture of the filament that best suits you, your 3D printer and your project. Consider the following recommendations when making a decision regarding one or another 3D filament:

- See if the extruder of your printer can reach the printing temperature recommended for a certain filament;

- Check if the glass transition temperature of the filament suits the purpose of your printed object;

- Take into consideration the environment you will be printing your item and consider the build material you will be printing on, to make sure that the odor and fumes, if released by such filament, are a problem for you or the people who will be in that area during the printing process;

- Consider availability of color, flexibility, durability, final finish, strength of the material;

- See if heated bed is needed for what 3D printing material.