With the most recent installment of the famous franchise wrapping up in theaters worldwide, and the hype that the film has been received by Star Wars fans across the Globe, we at Gambody thought to surprise them and released an amazing 1m+ scale Millennium Falcon 3D model. The model is unique, showing upgraded versions of various exterior elements, according to the 3D designers’ own views and approaches.

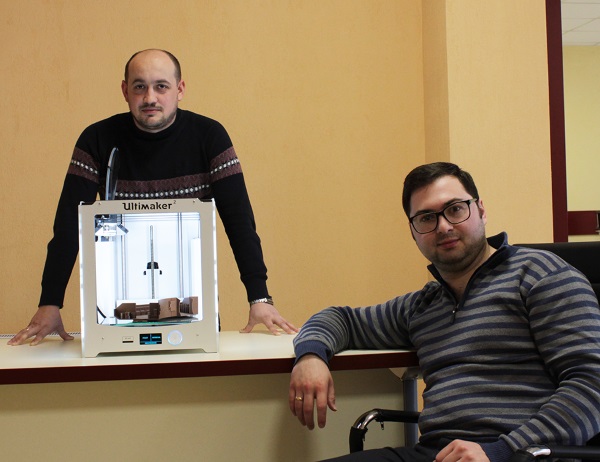

We sat for a chat with Sergiu Malic and Alex Vorojbit, Gambody’s 3D designers, and asked them about their experience of designing game related models, in general, and modeling the famous Millennium Falcon 3D model, in particular. Read the interview below.

Q. What got you into 3D design and when did you first hear about the possibilities of 3D printing?

S.M. I got my interest in 3D design from video games and cartoons in 3D. The three-dimensional world is an environment where one can express its ideas and thoughts, creating extraordinary things, from common objects that we use in our everyday life (furniture, household items, architecture models, car parts and etc.), to more unusual items (space ships, advanced robotics, fairy-tale, video/computer games, movie characters, monsters and etc.).

A.V.My first encounter with 3D printing technology was back in 2010. At that time, this technology was little known and almost unavailable for consumers. Nowadays, however, we witness a huge increase in number of home 3D printers and interest in modeling and printing 3D models by enthusiasts. The technology offers limitless possibilities. You can have a unique model with just a little imagination, desire, and a 3D printer, of course.

Q. What are your sources of inspiration?

S.M. I get my inspiration from everything that surrounds me: a toy that a child plays with, a car that drives on the street, drawings in a comic book, movies, and action video games to name just a few. Also, the Internet is an endless source of inspiration and the place where you can meet people that enjoy the same hobby and share and exchange ideas with them.

Connecting with and hanging out within 3D design online community is an activity that allows me to explore my peers’ views and reshape mine, where necessary.

Let’s talk more about that red car that is driving now on the street. It is a nice car, but in my head this car becomes spectacular. I imagine getting rid of that boring boot and mounting a jet engine in its place. I see it having wheels that transform into rocket turbines. I replace the front lamps with lasers and the rear lamps with propellers. In just several minutes I have altered the car to the extent that it can be considered a supercar.

A.V. This is a reality we all are waiting to see. But until then, 3D technology offers us the privilege to modify and create exclusive things.

Q. Why did you choose to design the epic Star Wars Millennium Falcon?

S.M. I am a Star Wars fan myself.

A.V. We both are!

S.M. True, we both are. We’ve seen all the movies and played the video games a billion times. Millennium Falcon spaceship is probably the holy grail of every 3D designer. It was a challenging project we accepted with the open heart and anticipation because of the model’s complexity. It is an epic spaceship, with fascinating exterior and interior design. We’ve made personal changes to the model and ensured that the STL files are easily converted for 3D printing.

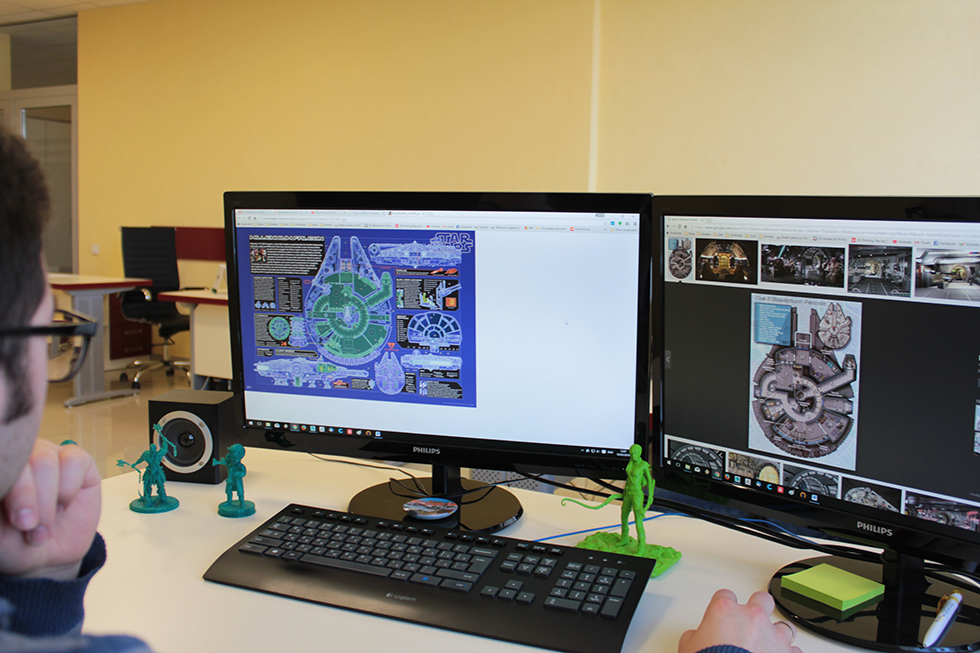

Q. What kind of research process did you follow to design the model?

S.M. The research was based mostly on playing the video game and taking screenshots of the ship from different angles. We used the same approach for the interior of the ship, but this time, we relied on the film. Once we had a large collection of Millennium Falcon images, both of its exterior and interior, we looked for engineering projects of the spaceship on the Internet, Wikipedia mostly. Having all this precious information, we drew the spaceship’s sketch on paper. While sketching it, we understood that this 3D model would have to be a large scale one.

That was when we decided to incorporate interior (secret compartments, cockpit access tube and cockpit itself, lounge seat and etc.) and exterior (guns, landing gear, functional boarding ramp) elements, as the project’s size allowed us to design even the tiniest of details.

A.V. The option of designing a tiny spaceship was out of the question once we had collected the pictures and had the sketch of the hulls. It was supposed to be a huge project and we dived into the challenge and designed one of the most epic Millennium Falcon 3D printable model. I mean, 1m+ scale Millennium Falcon, available for 3D printing, with a high detailed interior layout and upgraded version of the exterior hulls – what more could a true Star Wars fan want?

Q. What was the most difficult part to design? Why?

S.M. I can’t say that there was only one particular part that was difficult to design. The entire 3D model was hard to create, especially because we were dealing with the one and only Star Wars Millennium Falcon, a hugely popular and admired spaceship with a large fan base around the world. And we didn’t want to disappoint.

Nevertheless, the most challenging task was to design the smallest parts of the model. We had to consider the way they would act when being 3D printed. This pushed us to make changes to the original so that the final result met not only ours but the fans’ expectations as well.

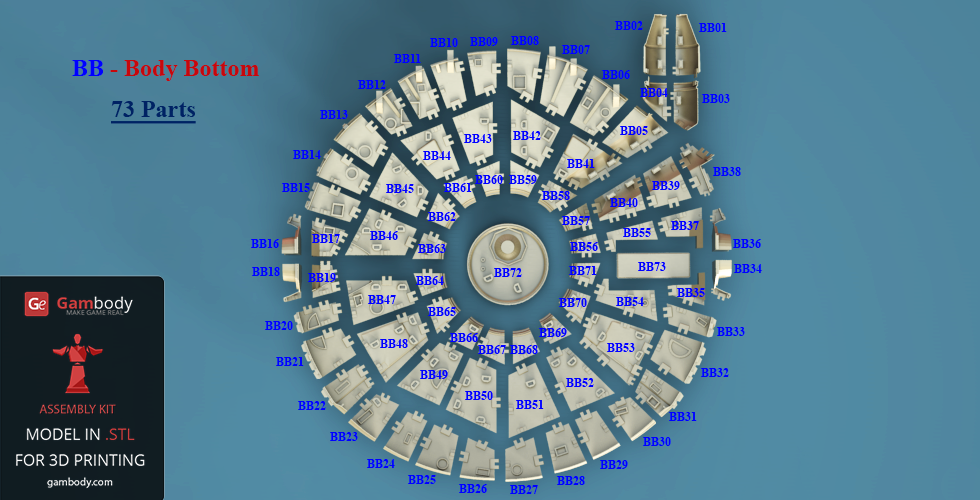

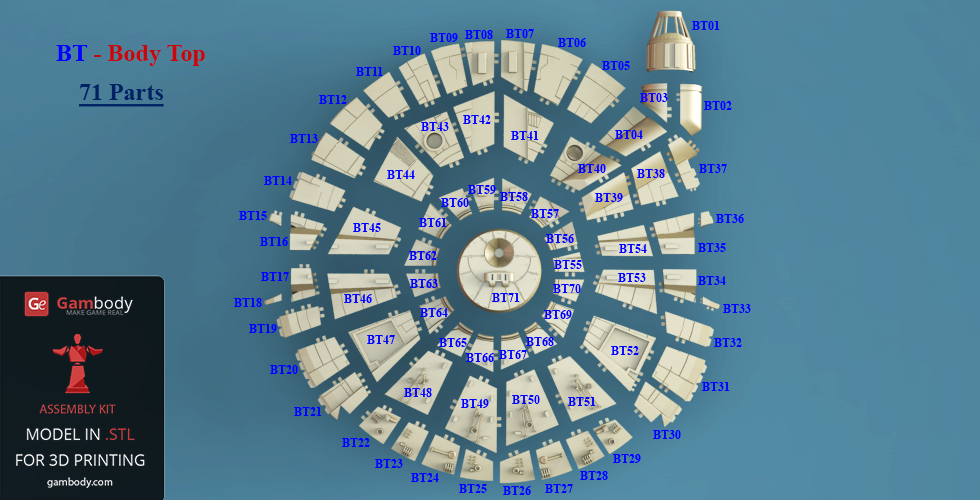

A.V. I must say that the hardest job was to design the top and bottom hulls of the model. We needed to take all printing factors into account, to make the model filament-friendly, as we say it in the office, which means that we made changes that would enable users to save filament when 3D printing the model. Another difficulty we faced was to make the ship’s hulls resistant, to hold the weight of all interior and exterior elements to be assembled.

S.M. In the end, we managed to design not only a high detailed 3D model but also a durable one.

Q. What pushed you to design a large scale 3D model?

S.M. First and foremost, I think is that such an impressive spaceship deserves to be replicated in large scale. Plus, we saw that there were no other big 3D printable models of Millennium Falcon available, which meant that we would be the first to deliver such an opportunity to all those who admire the engineering and technical construction of the ship.

Q. How much time did it take to model this impressive ship?

S.M. It is a project worth more than 800 hours of intense work. Although tiresome, I am thrilled that I contributed to its creation, investing a lot of time and effort to see it the way it is today.

A.V. 2.5 months of coming to work and going home with one thought in my head – designing a model that will exceed all expectations. We hope our work will be appreciated. In fact, we have already received a bunch of messages and positive feedback from 3D printing enthusiasts and Star Wars fans, which proves that our efforts are valued.

Q. What problems did you face while designing the 3D model?

S.M. As I already said, probably the biggest problem we faced was to construct the ship’s hulls in such a way as to hold the weight of the interior and exterior elements. We couldn’t afford to disappoint the Star Wars fans, so we spent a lot of time modeling and remodeling until everything fitted perfectly.

Q. Did you use any special techniques to make the work on Millennium Falcon 3D model easier?

S.M. I always start working on a model from scratch. Millennium Falcon 3D model was no exception from this rule. Having several years of experience in 3D modeling, I have already formed a sort of working process that helps me go through the project in an organized way. I always deal with big issues first, as they take more time and effort.

I can’t say that for this 3D model I invented a new technique to ease my work. I followed the same steps as I follow for any other 3D model I design. However, I made use of various 3D design software, like Autodesk MAYA, 3DS Max, ZBrush, CINEMA 4D, Keyshot.

Q. Let’s talk about 3D print testing of the model. Is there anything in particular the users need to know about the printing technique of this model?

S.M. We’ve designed the model as we would have done it for ourselves. Now, all the user has to do is to send the STL files to print. We’ve considered every detail: from plastic saving to final result of a printed part. Even CURA 3D printing software’s settings recommendations are taken from multiple printing tests carried out by us on our in-house 3D printer.

A.V. The files can be sent to print in the exact position they are zipped. If the user wants, he can rotate the part when sending it to print. However, it is highly recommended to not change the scale of the parts. Every part that our 3D model consists of has been separately designed to match one another. If you change the scale of one single part, the entire construction will be ruined.

S.M. We’ve tested everything many times and took all possible error factors into account. That’s why just follow printing recommendations and details provided on Millennium Falcon 3D model page on Gambody.

Q. How many parts does the model consist of?

S.M. The model consists of 380 parts: 279 parts for the exterior and 101 parts for the interior. Each part has been designed to be printed on an 18x19cm heated bed.

Millennium Falcon exterior kits include engine details and parts as cockpit, boarding ramp, guns, antenna and other.

It will take approximately one month to assemble the entire construction. That’s one hell of a puzzle. Although, we made sure that the assembly procedure was effortless, easy and fun for the user. We’ve created a step-by-step video of the assembly, and numbered each part to avoid any confusion.

Q. How strong is the assembled structure? Will the joints hold? What reassurance can you give to all those who want to buy the STL files and print the monster on their home 3D printer?

S.M. I can guarantee that the assembled structure is strong enough to hold all interior and exterior parts. We’ve remodeled the joints to fit the parts and to hold the weight of the construction. You will see that the joints we modeled for the ship match the ship’s scale. So there is no reason for the user to worry about that his Millennium Falcon model will collapse. We spent a lot of time considering every problem and made sure that a solution was provided.

Q. Are you satisfied with the result? Would you have changed something?

S.M. The result is beyond my expectations. Everything worked out the way I envisioned and planned. I wouldn’t change anything to the model. Because everything there was to be changed we had already done it during the modeling process.

A.V. All changes have been made to ensure an error-free printing experience of Millennium Falcon 3D model.

Q. What can you say about the model to convince Star Wars fans to have it printed?

S.M. It’s the user’s choice to print it or not. All I can say is that the sight of Millennium Falcon 3D printed model, mounted on its powerful landing gear, with a fully functional boarding ramp and opened top hull of the ship, allowing an unimpeded view of the interior layout, offers priceless excitement. It is a one-of-a-kind prototype, available only at Gambody.

Q. What future 3D design projects do you have in mind?

S.M. I will keep on modeling video game characters, vehicles, weapons and other items. It’s what gives me the greatest of pleasures. It is not excluded that I will be modeling something else from Star Wars and I hope to repeat the success we have with Millennium Falcon 3D model.

A.V. We will definitely model another Star Wars-inspired vehicle or droid. Both the movies and the video games abound in captivating and complex engineering constructions.

S.M. I like complicated things, regardless of how much time it takes to make them. I only hope that the users like and enjoy everything we model and do.

We wish all readers patience, detailed 3D models, and high-quality plastic filament for their 3D printers.