Resin is impressive material for 3D printing which helps to craft smooth surfaces, highly detailed models and high-quality figurines. It provides numerous possibilities for post-processing and model finishing. However, its main drawback is the high price, which causes users to search for the best ways to save as much resin as possible. DLP/SLA Eco version of 3D printing files is one of the methods to try in 2020.

Working with DLP/SLA Eco version of STL files offered on Gambody – Premium 3D printing marketplace allows saving a considerable amount of resin without downscaling the model.

DLP/SLA Eco Version of 3D Printing Files

Modern resin 3D printers provide outstanding results even when used at home. DLP and SLA printers that work with resins are more expensive than FDM/FFF 3D printers, and still, you can find affordable machines among them.

Since both a resin printer and resin material it uses for 3D printing are money-consuming, users wish to low down the costs of the final print. Gambody – Premium 3D printing marketplace came up with an impressive solution. It began to optimize DLP/SLA Eco version of STL files for 3D printing models and figurines.

However, when you wish to save resin and still receive a high-quality result while working with DLP/SLA Eco version of 3D printing files, you need to be attentive. Do not forget about adding drain holes in hollowed-out models and follow other tips.

Read also: What I Need to Know After Buying a 3D Printer: Simple 3D Printing Guide for Beginners

How to Work with DLP/SLA Eco Version of STL Files

When a print fails, it causes the most significant waste of resin. That is why it is so essential to use DLP/SLA Eco version of STL files the correct way, with the best suitable settings and actions pre-taken in advance.

Follow these best tips to economize on resin costs with DLP/SLA Eco version of 3D printing files offered on Gambody – Premium 3D printing marketplace.

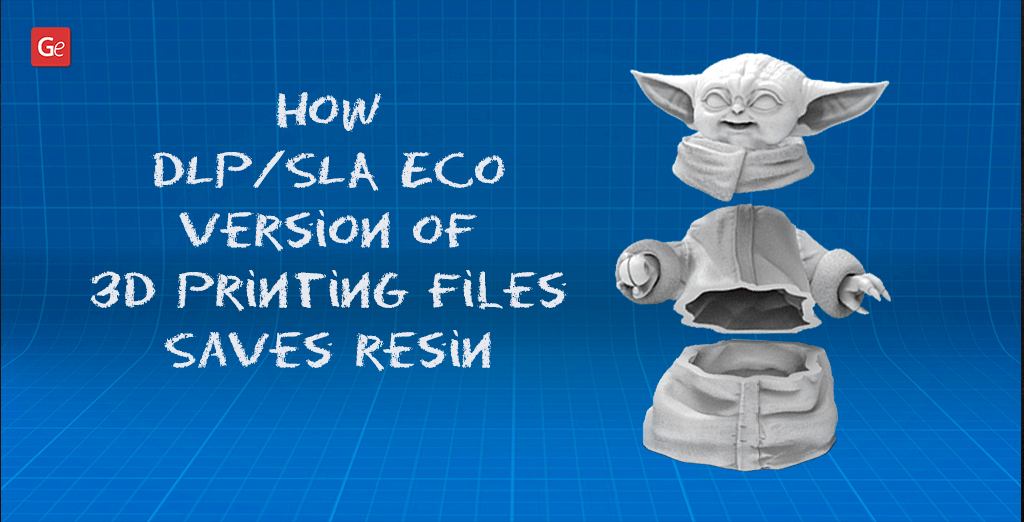

1. How DLP/SLA Eco STL Files Appear on Gambody

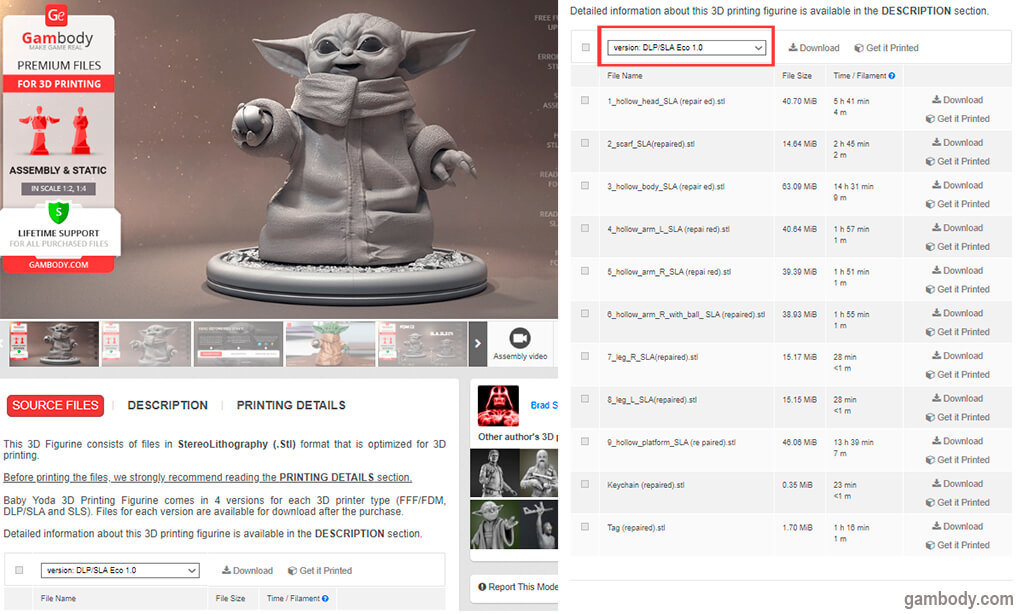

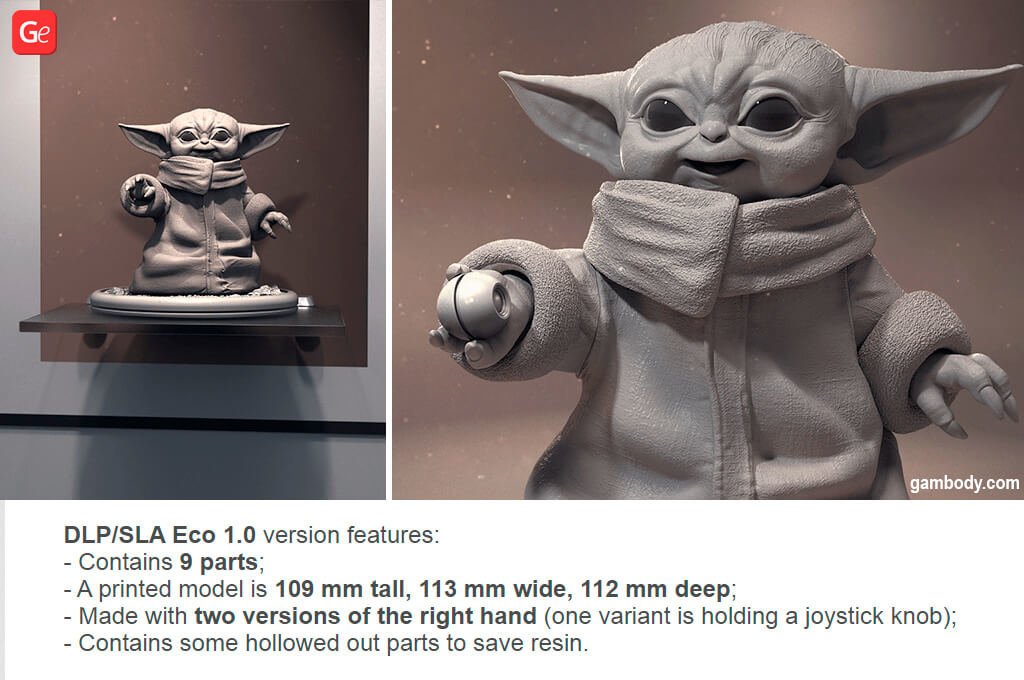

Each 3D printing model available on Gambody marketplace is adapted for most 3D printers. Thus there are several versions of STL files that are optimized for different types of 3D printers, including DLP/SLA Eco variant.

This version of STL files on Gambody marketplace contains some hollowed-out parts to save resin.

2. Download DLP/SLA Eco 3D Printing Files

When you choose to save resin on your DLP or SLA 3D printer, you can download the DLP/SLA Eco version of STL files after ordering your favourite model.

These files include hollowed-out parts of the models, which is an essential step to take when it comes to lowering down your resin costs.

Gambody team chose to make the wall thickness of 3.5mm in hollowed out parts. It is a perfect thickness that makes sure the walls are not too thin to cause the possible breaks off. It is still light enough to save the maximum amount of resin material during printing.

However, you still need to prepare DLP/SLA Eco STL files version for printing in two main ways:

- By positioning model parts for the best-printed result;

- By adding drain holes to avoid bubbles of liquid inside.

3. Prepare DLP/SLA Eco STL Files for 3D Printing

Meshmixer, ChiTuBox and other slicing software help to prepare STL files for printing. They are used to automatically or manually place each printing part to a particular position which can lead to a better printing result.

Every person likes to position the parts according to personal tastes and likes, experience and skills. Thus Gambody team leaves it to the natural taste of each user to manually add drain holes (also known as vent holes or escape tunnels). Users should apply these holes after the printing parts are given their final position.

When to Add Drain Holes for Resin Printing and When Not

There are two main opinions among resin 3D printing enthusiasts regarding the drain holes.

Those users whose printer crafts a shell upside down (bottom-up machine) usually require no holes at all. They can work with a hollow model without encapsulating resin inside. However, users whose 3D printer lowers the build platform into a tank (top-down machine) can easily trap resin in a hollow model if it lacks drain holes.

A hole added to the bottom of the object (closer to the build plate) helps to normalize the pressure between the hollow object’s inside and outside walls. It results in a successful release of extra resin during the 3D printing process.

4. How to Add Drain Holes to a Model

There are several ways of completing this task. It is possible to work with Meshmixer, ChiTuBox and other tools. We will explain some of the methods in details; however, you can choose any slicing tool for this purpose.

Method 1. Working with a Boolean tool in Meshmixer

Here is how to add drain holes to a model by using a Boolean tool offered by Meshmixer.

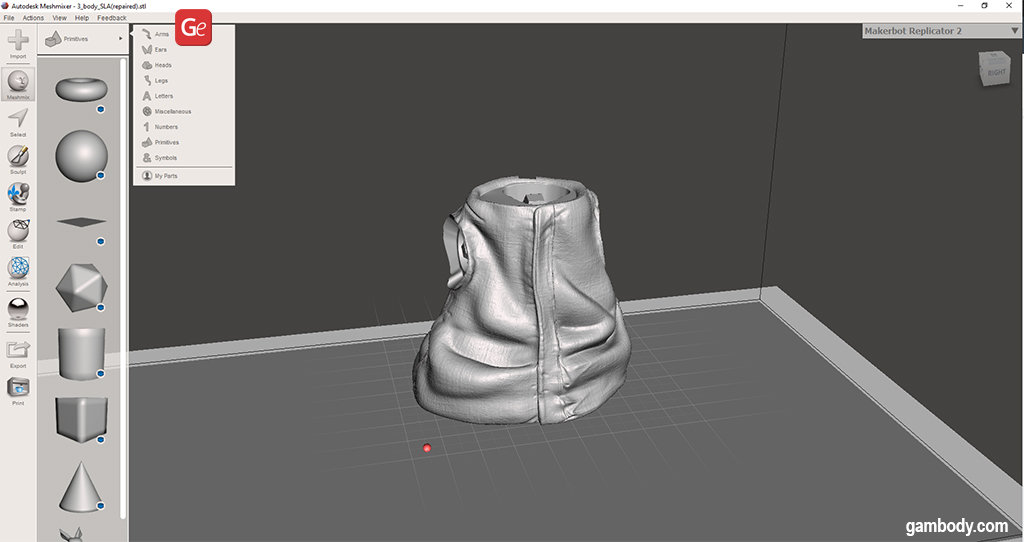

Step 1. When you wish to add a drain hole in a hollowed-out part of the model using the Boolean tool, you should work with “Cylinder Primitive” tool in Meshmixer.

Step 2. Drag your cylinder from the software menu to the part of the object where you wish a drain hole to appear.

It is best to apply such an escape hole in the base of the model. This way you will prevent the building of a pressure differential as you 3D print.

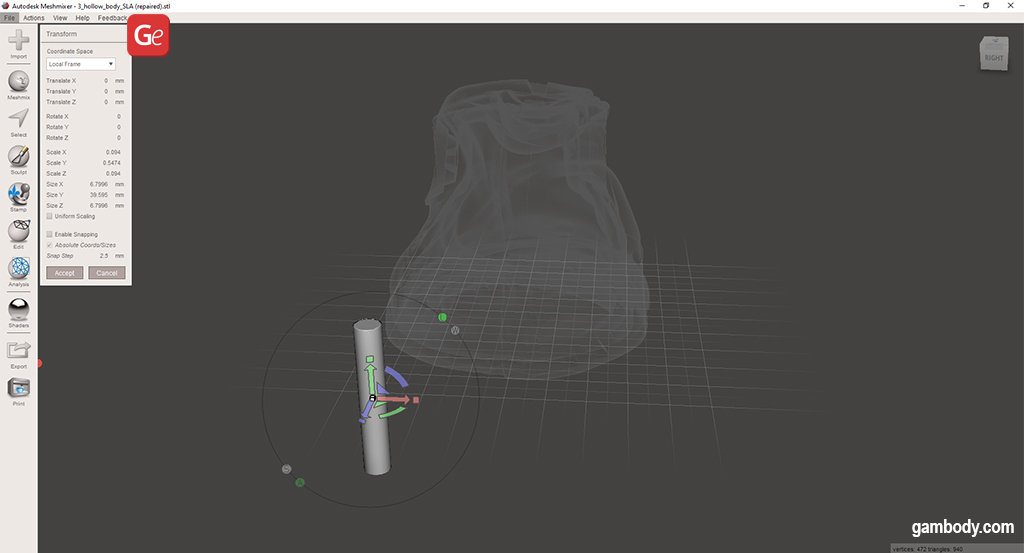

Your drain hole can be between 1.5 and 3 mm in diameter. Make sure that it goes through the object wall thickness by working with “Create New Object” tool and clicking on “Accept” when you are happy with the result.

Step 3. It is time to stretch the height of your cylinder via “Transform” tool.

Once you have transformed your future escape hole, you will have to click on the “Accept” option.

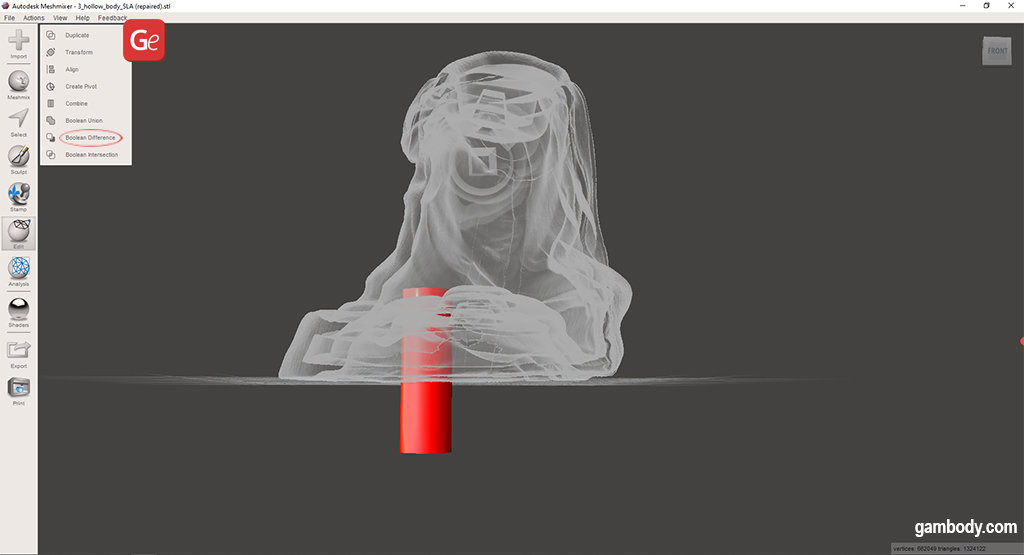

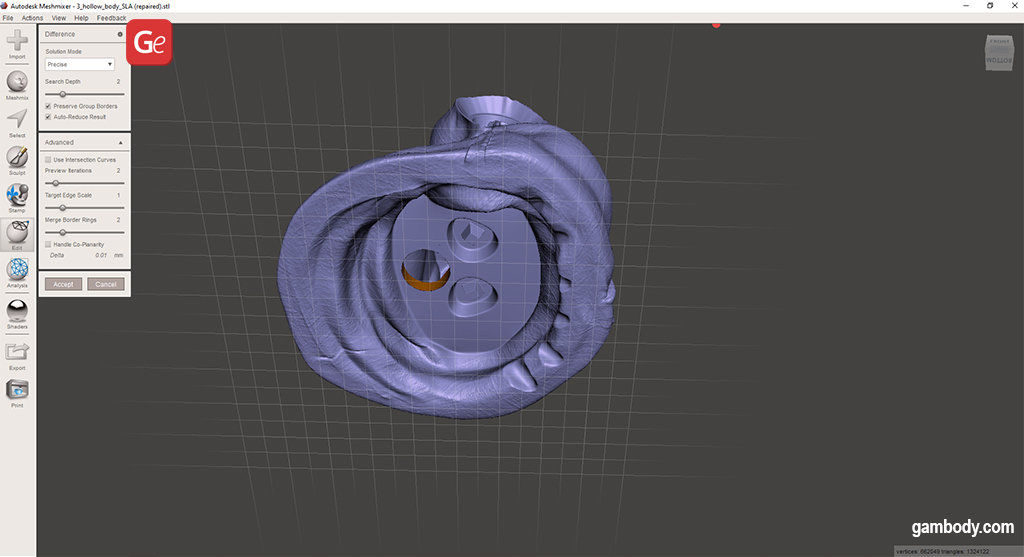

Step 4. Now click on the object. Then click on your newly created cylinder (which will be the hole soon), and a menu with “Boolean Difference” will pop up.

This operation will finally create a drain hole in the object.

Method 2. Adding Holes with ChiTuBox

Besides Meshmixer, ChiTuBox also helps to make vent holes in a hollowed-out model and optimize the project for resin 3D printing.

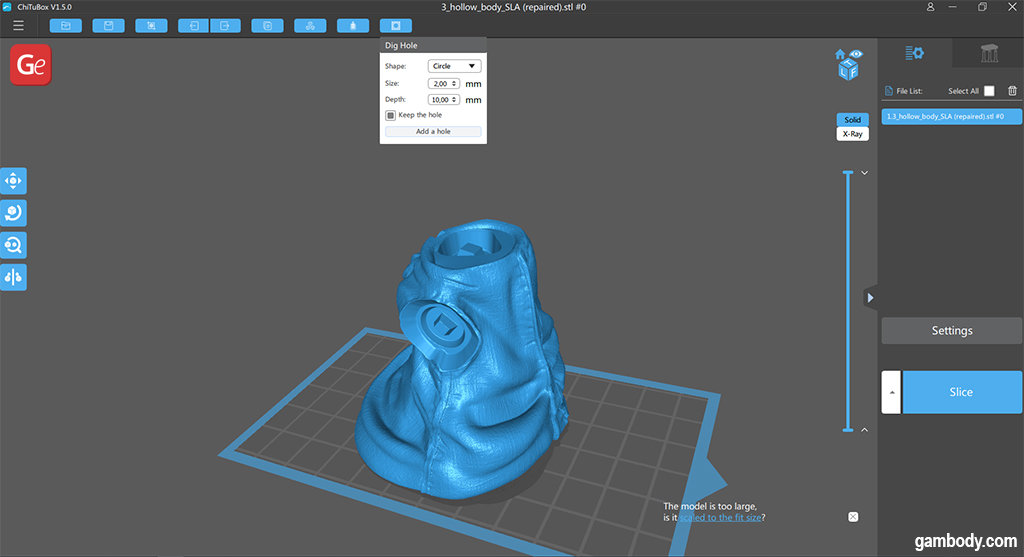

Step 1. ChiTuBox has a separate upper-bar menu button for making drainage holes in a 3D model.

Click on “Dig Hole,” the last button in the row, after you orient the object for printing.

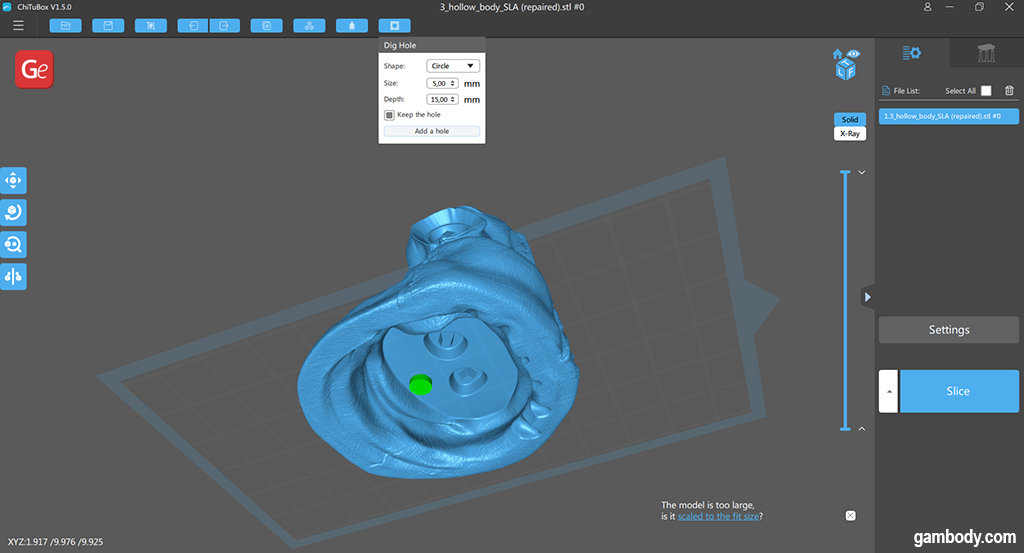

Step 2. Choose the hole’s shape. It can be a square, circle or hexagon. Select the preferred diameter.

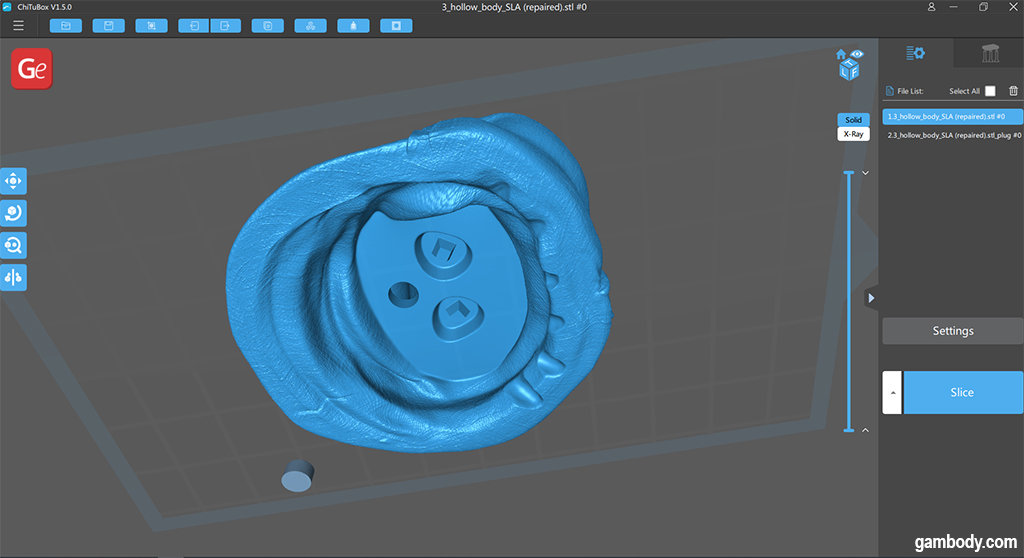

When you are happy with your settings, click on the “Add a hole” option indicating the drilling area. The program will perform its calculations and create a hole.

It is best to add a hole to the base or any least visible area closest to the build platform.

How Many Drain Holes a Model Needs

It is best to add two holes in a hollowed-out model. One hole should be located at the bottom of the object to allow resin flowing out during printing. The other hole should be placed on the surface of your choice. It will help air to vent.

You can add an extra hole in the part with overhangs (if there are any).

The diameter of a drain hole can be between 1.5 to 3 mm, and air vents can be from 1 to 3 mm.

4. Print It

Once you convert STL files of your 3D printing model into a G-code and save it on the SD card, you can begin printing and saving resin material.

Here is how you can patch drain holes after crafting your project:

These are main tips, secrets and guides associated with DLP/SLA Eco version of 3D printing files which you can download on Gambody marketplace. It is a convenient way to save resin while crafting your beloved characters and outstanding figurines. And Gambody Facebook group is a friendly place to share your masterpieces.