Gambody has compiled this 3D printing guide to help all beginners learn the fundamental theories, essential tools, concepts of how to 3D print. Uncover the history of 3D printing, popular hardware, software and the supplies needed for successful results.

Follow friendly tips for choosing your first 3D printer, and everything else related to the fantastic technology everyone can employ at home today. We’ll make sure to update this free beginner’s guide to 3D printing to include new compelling content, striking images and prospective ideas.

Beginner’s Guide to 3D Printing

Additive manufacturing has the power to generate complex geometries and valuable parts for medicine, aerospace, defence, automotive and other industries. The 3D printing community is constantly developing, improving 3D printing skills, exploring new 3D printers and finding new applications for innovative technology.

Newbies and advanced users searching for interesting facts about additive manufacturing technology, its potential and development, will find all these details in the free Gambody’s guide on how to 3D print.

Our comprehensive guide includes various details about materials, processes, applications and answers to common questions. It will be helpful to users with different 3D printer machines and skill levels.

Jump to a Section:

- What Is 3D Printing

- History of 3D Printing

- 3D Printing Technology

- Basics of 3D Printing

- 3D Printing Applications

- 3D Printer Beginner Guide

- How to Choose Your First 3D Printer

- Questions About 3D Printing

What Is 3D Printing

Technologies change and improve human history, develop the whole world and make the lives of millions of people much better. Can you imagine your life without a light bulb, car, train, aeroplane, not to mention the Internet? All these innovations opened many great possibilities and have had a huge impact on many generations. And additive manufacturing (shortly abbreviated as AM) also has a great potential to change everyday lives and influence all known industries.

The first thing a newbie asks is, “What is 3D printing?” Today the term “3D printing” is associated not only with additive manufacturing but also with layer manufacturing, additive techniques, freeform fabrication, desktop fabrication and other phrases. Unlike in subtractive manufacturing where a big piece of material is shaped through cutting/forming, the 3D printing definition hints that this technology grows new parts out of material.

Several years ago, many believed that 3D printing was just technology from Star Wars or another movie. But the more affordable 3D printers become, the more people take advantage of the incredible process of creating physical objects from digital 3D models.

3D printing is basically building a real object out of a digital format by laying down layer after layer of materials (plastic, resin, metal, etc.) at the sub-mm scale. While it is completely different from all other traditional manufacturing processes, a range of techniques could be used to 3D print models, and we will discuss each one in our ultimate guide.

Understanding what is 3D printing is the first step to mastering this innovative production process to create useful household parts, home items, medical casts, collectable figurines, accessories, automotive components and even food.

Read also: Best 3D Printing Websites with Free STL Files

History of 3D Printing

The “official” introduction to 3D printing was in 1986. Still, the roots of this technology began to grow in the early 1980s. In 1981, Japanese scientist Dr Hideo Kodama applied for a patent in laser beam resin curving. Unfortunately, his application ran out of a specified 1-year period due to a lack of funds.

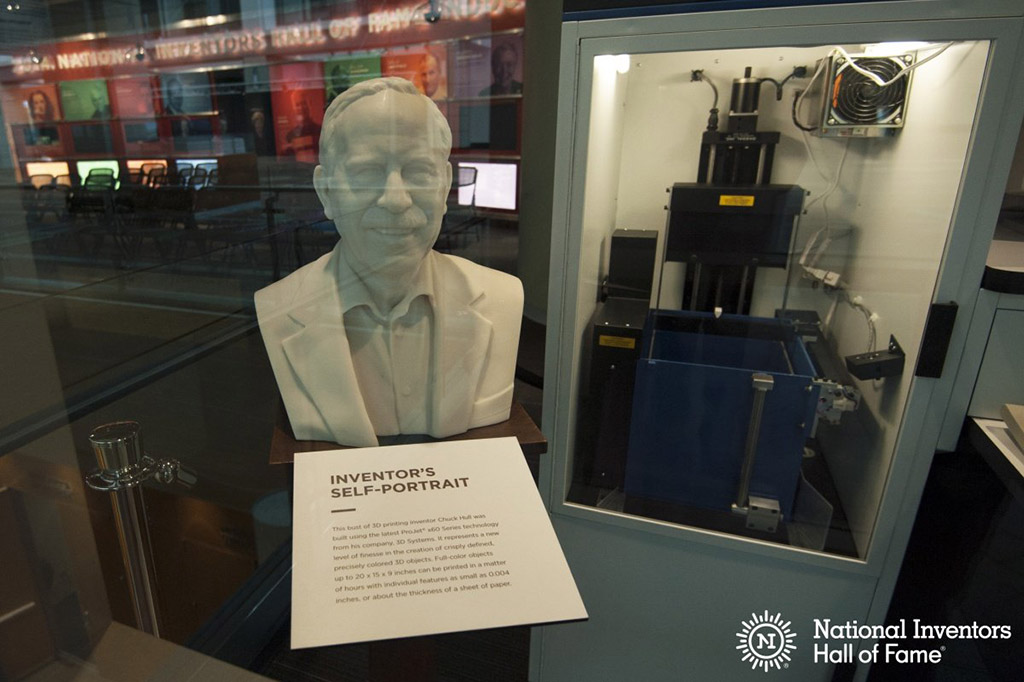

In 1984, American engineer Charles (“Chuck”) Hull filed a patent for the stereolithography process. A year earlier, he showed the very first 3D printed part, and then founded 3D Systems.

Since then, his name is associated with one of the SLA 3D printer inventors and the still-popular STL mesh file format. Hull’s term for stereolithography (“Apparatus for Production of 3-Dimensional Objects by Stereolithography”) was the official name of the patent granted in 1986. And the history of 3D printing began.

First 3D Printer

In 1986, Hull was one of the founders of 3D Systems, the world’s first 3D printing company. And in 1987, the company produced the world’s first 3D printer.

It was an SLA-1 machine which you can see today on display at the National Inventors Hall of Fame Museum in Alexandria, VA (USA). It built models by laying and curing layers of UV-sensitive resin with a UV-laser and constructing a 3D geometry one cross-section at a time.

In 1987, Carl Robert Deckard invented Selective Laser Sintering (SLS) technology. He filed a patent, which he was granted two years later. SLS used a laser to fuse plastic powder in a heated chamber and printed with nylon and thermoplastics instead of resin as in SLA machines.

DTM Inc got a license for using SLS. And later, this company was acquired by 3D Systems.

In 1988, S. Scott Crump invented Fused Deposition Modeling, known as FDM, getting a patent in 1992. Crump was the co-founder of Stratasys Inc.

In 1989, Hans Langer founded EOS GmbH in Germany (Europe). This company focused on developing the laser sintering (LC) processes. And a year later it started to sell “Stereos” systems.

How Long Has 3D Printing Been Around

The 3D printer creation didn’t change the world at once. The new technology was expensive and sounded fantastic, but not realistic. Only in the 1990s did society pay serious attention to additive manufacturing.

The 1990s and 2000s introduction to even more technologies was exciting:

- Solidscape invented resin 3D printers to create “wax-like” patterns for lost-wax casting;

- Z Corporation licensed the binder jetting AM developed by MIT* to produce sand moulds;

- Extrude Hone Corporation (later ExOne) obtained an exclusive licence for MIT’s technology to develop and commercialise metal binder jetting systems;

- Helisys Inc. (now Cubic Technologies) developed laminated object manufacturing (LOM) that fused layers of paper;

- Arcam (now acquired by GE Additive) developed an electron beam melting (EBM) process for creating fully dense metal parts directly from metal powder;

- More 3D printing processes were introduced, including selective laser melting (SLM), LaserCursing and direct metal laser melting (DMLM).

*Interesting fact. MIT (the Massachusetts Institute of Technology) initially coined the term “3D printing” related to the metal binder jetting technology it developed.

The early 2000s also were the years of the creation of essential 3D printing companies that mainly used FDM, SLA, SLS and DMLS 3D printers.

From 2005 to the early 2010s, ExOne was the only company to offer metal binder jetting services and systems.

In 2007, 3D Systems introduced the first 3D printer for under $10,000. But at that time, it was believed that the industry would get a wider audience as soon as the first 3D printer under $5,000 will be released. And Desktop Factory was founded to complete that goal. However, 3D Systems acquired it in 2008 vanishing the plans.

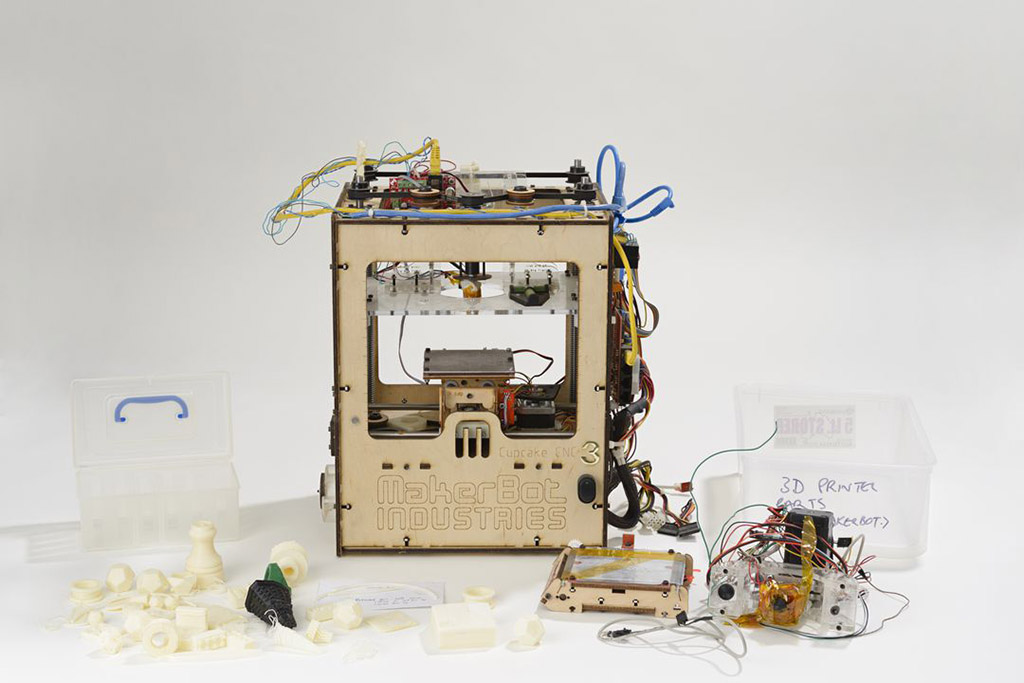

In 2009, the history of 3D printing got another happy turn. The foundation of MakerBot Industries, LLC led to the creation of the first desktop 3D printer MakerBot and DIY kits.

This new class of machines soon conquered the hearts of hobbyists and homemakers looking for affordable solutions and an opportunity to create open-source desktop machines independently. It was also the rise of the RepRap community that loved the open-source development of 3D printing and the idea of introducing entry-level machines.

In 2011, Formlabs was founded, which led to the creation of the first desktop SLA 3D printer. Then the world saw the creations and ideas by Markforged, Desktop Metal, MakeXYZ, Xometry and other companies. Some of them produced 3D printers that printed with prosumer filament, plasticised metal rods, etc. Others connected consumer machines with users and offered 3D models for manufacturers to fulfil the projects bought by consumers.

Other major turns were 2012 and 2013. The introduction of alternative AM processes (DLP by B9Creator and stereolithography by Form 1) through Kickstarter were a huge success. Stratasys acquired Makerbot, and the 3D printing revolution goes on.

3D Printing Today

The last years have made additive manufacturing (desktop fabrication) popular among ordinary users. There are several reasons for this.

Firstly, many of the original patents granted to 3D Systems, Stratasys and other companies have expired. Thus, the market faces many new players who compete for the customers in professional and hobby fields. Secondly, the high demand for 3D printing led to the creation of service companies that print models and ship them to customers.

As a result, everyone wins. The three companies that pioneered 3D printing, 3D Systems, Stratasys and EOS, are still important players in the market. But the industry also witnesses a growing number of small and big competing companies.

Today, hobbyists and businesses witness a huge amount of 3D printers of various sizes and at different price ranges, from $100 (for kids) to thousands of dollars for industries. It is now possible to 3D print with PLA, PETG, ABS, Wood filament, resin, metal powder and other materials.

The introduction of desktop 3D printing to more and more people also influenced the 3D design market. CAD and other 3D design software became more affordable.

3D Printing Technology

When you wish to learn 3D printing, it is a must to understand the processes. The 3D printing technology is based on different techniques. However, they guarantee the same result – a machine manipulates a digital model and manufactures a desired shape through material addition.

The traditional manufacturing process often wastes up to 90% of the original material formed to the desired shape. However, it is not an issue in 3D printing.

In additive manufacturing, an object is made directly with a machine adding layer by layer of material in numerous ways. To simplify the definition of 3D printing for dummies, it is as if you build a model using Lego blocks. Everything is fast, relatively simple, and each piece fits in its place. Often, you can avoid assembly by tricking the geometry with 3D printing software.

3D Printing Methods

In recent years, 3D printing technology is no longer an industrial-only process. Today, additive manufacturing is accessible to individual hobbyists and small businesses. So, beginners need to learn about 3DP methods and techniques.

You will find all the most essential details in our beginner’s guide to 3D printing below.

Stereolithography (SL)

The history of 3D printing began when Chuck Hull invented stereolithography. It is the very first process that introduced the world to new technology.

This 3DP process is based on a laser that cures resins (photopolymers) poured in a vat to recreate solid, highly detailed parts. An SL 3D printer reads the 3D information supplied via STL files and directs its laser beam to the X and Y axes hardening resin when the laser “touches” its surfaces.

A machine completes the projects layer by layer. And the vat provides portions of resin just enough for each layer. When a model is 3D printed, and resin is cured, the platform rises out of the vat. Now the project is ready to be removed from the plate.

The stereolithography 3D printing technology is a complex one. It can build simple and complex models. However, it is necessary to use supports to recreate undercuts and overhangs. They are not a part of the project, and users remove them manually after the whole piece is finished.

SL 3D printing technique requires additional post-processing actions. Objects 3D printed in resin must be cleaned of support structures and cured in a machine that uses intense light to harden the material.

Even though stereolithography was the first 3D printing process introduced in the 1980s, it is still considered one of the most accurate technologies.

Read also: Creality Halot-One CL-60 Resin 3D Printer Unboxing and Review

Digital Light Processing (DLP)

This 3D printing method is similar to stereolithography yet differs from it. Just like SL, DLP also uses photopolymers as the material. But its light source is different.

Instead of a laser, DLP 3D printers use an arc lamp or a similar light source with a liquid crystal display or deformable mirror panel. This light source can cure the whole surface of the resin layer in one pass.

DLP is way faster than the SL 3D printing process. It also results in excellent quality and an impressive resolution of 3D prints. But it also requires less resin minimizing the waste of material.

Like stereolithography, digital light processing also requires support structures for overhangs and complex parts and post-processing.

Laser-Based 3D Printing Process (LS, LM)

DLP and SL technologies use photopolymers (resins). Still, laser sintering (LS) or laser melting (LM) is a different process that needs powdered materials.

As explained by experts, this 3D printing method reads the 3D data and traces the laser over the bed with powdered material. “Touching” the material, the laser helps it fuse or sinter, causing the particles to form into a solid object.

Before working on each new layer, the printer smoothes the powder over the printer bed. Then the process repeats until each layer is laid and fused or sintered with the previous course.

Here is what you should learn about laser-based 3D printing technology. It uses a sealed chamber to work on models. It is an essential requirement because the temperatures are high, and the procedure is rather specific. It has to melt the powdered material, and when the 3D print is finished, you should remove the bed and get rid of excess powder.

Unlike SL and SLP processes, this 3DP technology requires no support for recreating complex models with overhangs and other complicated forms. It might also result in more substantial parts if using plastic or metal materials. However, the models’ surface is not as perfect as in the two previous methods.

Its main drawback is the long time required for the model to cool down and the lack of accuracy in 3D printing.

Fused Deposition Modelling (FDM and FFF)

Many enthusiasts and hobbyists prefer the FDM 3DP technology. Fused Deposition Modelling is viral nowadays, and it is the most affordable technique.

However, the term FDM was trademarked by Stratasys. Only this company can produce 3D printing machines naming them “FDM” 3D printers. To avoid legal issues, young startups came up with the FFF term standing for Fused Filament Fabrication or Freeform Fabrication.

Thus, when you see FDM or FFF 3D printer, it uses the same 3DP process employing extrusion technology. The technology uses a heated extruder that deposits melting filament layer by layer onto a 3D printer bed (build platform). Each layer hardens, bonding to the previous layer before the next one is extruded.

FDM and FFF 3D printers have to use supports when 3D printing overhangs and complex geometries. Removing all support materials manually once the 3D print is finished is necessary, and this process could be complicated and time-consuming. However, modern FDM/FFF machines with dual extrusion heads could make many issues nearly unnoticeable.

The most common filaments used in one of the most popular 3DP processes are PLA, ABS, PETG. But many professional and even entry-level machines can now print with Wood, HIPS, TPU, TPE, Glow-in-the-dark plastic and other materials.

This method is not as accurate as DLP or SL. Still, the technology is constantly improving, and the results could impress you.

Read also: Anycubic Vyper 3D Printer with Auto-Levelling: Review, Specs, Price, Tests

Jetting 3DP Methods

When you learn about 3D printing, you will encounter two similar jetting processes known as binder and material jetting. Often, they are called “Inkjet” technology.

Modern 3D printing methods allow making food. Binder jetting is such a technology. It uses a powder-based material (food, ceramics, sand, etc.) and a binder that serves as an adhesive between layers of powder. The 3D printer fuses each layer and keeps adding layer after layer until the project is done.

The powder bed helps to eliminate supports working similar to laser-based 3D printing technology. Also, the binder jetting process makes it easy to add different colours to the binder and create full-coloured parts.

In material jetting, liquid photopolymers are usually used to build layers. A UV laser cures them layer by layer once the jet heads jet the 3D printing material. This technology makes it possible to deposit materials with different characteristics simultaneously and create unique products. Finished 3D prints are very accurate and smooth.

Laminated Object Manufacturing (LOM)

Helisys Inc. (now Cubic Technologies) developed LOM in the 1990s to form objects out of paper or other materials. In this process, adhesive-coated paper is laminated layer by layer, glued together and shaped to the desired form with a laser cutter. Plastic and metal could also be used.

Often, post-processing work is needed. It might be necessary to modify the 3D printed model by drilling or machining it until the prototype is fully prepared.

Laminated Object Manufacturing technology can use different layer resolutions depending on the thickness of the adhesive-coated paper used to produce 3D prints. The technology is a cheap one but not precise. Besides, LOM 3D printers are more expensive than FDM or resin machines.

Selective Deposition Lamination (SDL)

When you read 3D printing for dummies, you will find a comparison of SDL with LOM. But these two methods are not that similar.

Mcor Technologies developed its Selective Deposition Lamination technology in 2003. And even though the company was liquidated in 2019, its assets were purchased by CleanGreen3d Limited.

The SDL 3D printing process was based on cutting and bonding regular A4 or letter paper layer by layer to make objects. The machines deposited more adhesive material to the main parts of the model and less to the surrounding areas (supports) for simpler removal. Also, pressure was used to bond the layers better together, and a tungsten-tip blade cut a sheet of paper at a time to form the required shape.

SDL was the most eco-friendly 3D printing technology because it only needed standard paper and adhesive material and required no post-processing work. Besides, it relied on CMYK colours and could replicate coloured 3D prints such as maps, buildings, anatomy, etc. Its main limitations were the build volume and the inability to produce complex models.

Electron Beam Melting (EBM)

This process helps to 3D print solid parts using metal powder. Arcam (now a subsidiary of the American company Harman) introduced it to the medical, aerospace and automotive industries.

Unlike metal laser sintering technology, EBM uses an electron beam as its heat source instead of a laser. Such a system requires a high vacuum and operates at a high temperature of 1000°C (1832°F). It melts metal powders and 3D prints objects layer by layer.

The Electron Beam Melting 3D printing process allows the creation of complex geometry of high quality.

Read also: 3D Printing Troubleshooting Guide to Fix 10 Common FDM 3D Printer Issues

Basics of 3D Printing

Understanding a 3D printer, how it works, and the basics of 3D printing is a must when you wish to master the additive manufacturing technique.

3D printing is best explained via a 3D printer anatomy. So, looking at the diagram and understanding the processes will help you get started and grow to an advanced level soon.

FDM 3D Printer: How It Works

Different 3D printing technologies use different anatomy for their machines. This mini-chapter focuses on an ordinary FDM 3D printer because the FDM/FFF process is the most popular and affordable today. Most hobbyists who love to 3D print have an FDM machine at home.

A beginner’s 3D printer comes with a base and a frame. It consists of X-, Y-, and Z-axis:

- X-axis is responsible for the left-to-right movement;

- Z-axis moves up and down;

- Y-axis is moving front and back.

An average FDM 3D printer has an extruder, hot end, printer bed, filament feeder, often a display screen and other elements. The function of each most significant hardware part is explained below.

Extruder

An extruder is a moving part of a 3D printer. It can be a Bowden or Direct Drive type. Its primary function is to extrude the melted plastic filament and deposit it onto the printer bed.

An extruder is usually installed on the X-axis and moves along the Y- or Z-axis. It consists of an extruder head with a small hole for the filament to pass through and a feeder.

Hot End

Extruders pul and feed 3D printing material to the hot end. Many extruders have integration within the hot end. Still, some are built away from it, pushing the plastic through the Bowden cable.

The hot end has a heater, temperature sensor and a tip for feeding the 3D printing material. The tip is called a nozzle. Its hole can be 0.2 mm, 0.4 mm, 0.6 mm, 0.8 mm. And if your printer’s nozzle is too small for you, you can learn how to switch nozzles to print quicker.

There are also machines with two extruders, each with its hot end. But they are more expensive, and you can often reach a similar effect by 3D printing two colours with one extruder.

Printer Bed

The extruded layers of filament reach the print bed and create a 3D printing model a layer at a time, repeating the process until the object is finished.

There are two types of 3D printer beds – heated and non-heated. Depending on their type, you will have to add glue or painter’s tape to the surface or keep the bed heated while 3D printing. The heat that can reach 40-110°C (104-230°F) and above prevents layers from warps and other issues.

Frame

Every FDM 3D printer basic hardware includes a frame. It is a mechanical “body” mainly made of metal that holds all the gears, feeders, the build platform, heaters, coolers, etc.

It is excellent that the frame is extra sturdy and convenient. It plays a vital role in the 3D printing process and influences the accuracy of the prints.

Motion Control

Frames usually have a controlled portion, pulleys or belts because they have to move 3D printer portions along the X-, Z- or Y-axis.

For example, the build platform can travel up and down the Z-axis. Then the print head could go in X- and Y-direction to deposit the filament onto the build bed and print a model layer by layer.

Bed Levelling

All FDM 3D printers require bed levelling. Some machines make users do it manually once in a while; others require this action before every new 3D print.

But there are desktop printers with a fully automated bed levelling system. Using a 3D printer with an automated mechanism is way more accessible and comfortable than a device with a manual system.

Bed level is a measurement of distances between the bed and print head in various platform parts. A 3D printer should understand these measurements to compensate minor differences in the printing area and eliminate errors and failed 3D prints.

Build Plate

It is fantastic when a 3D printer has a removable build plate on its bed. It is much easier to remove 3D printed models when you can remove the plate with the model.

A build plate has an essential role in the 3D printing process. As explained by enthusiasts, it is a must for the first layer to adhere well to this sheet. Good bonding with the build plate results in a successful 3D print.

Filament

All FDM/FFM 3D printers print with filament. It is plastic 3D printing material that is not a part of the 3D printer. But without filament, a 3D printer will not work.

The two most popular filaments are PLA and ABS. However, modern machines can also print with PETG, WOOD, TPU and other materials.

P.S. Some people compare FDM 3D printing basics to glue guns. Like in this accessory, the filament (as if glue) is heated until it starts to melt and extrude to build layers.

Read also: Best Tips on How to Store 3D Printer Filament

Other 3D Printer Basics

DMLS, SLM, SLS (LS) machines use powder material to 3D print objects, while SLA and DLP 3D printers require resin. When talking about the basics of 3D printing, we must mention the main parts of these 3D printers.

Unlike FDM machines that come with an extruder, powder- and resin-based 3D printers have a vat for 3D printing material. They also come with a light or laser source to fuse or cure molecules and an elevator that moves the build platform.

Laser or Light Source

3D printers that build objects using powders or resin rely on a laser or light source. It could be an infrared or ultraviolet (IR or UV) beam or laser that cures (hardens) the model parts.

When a machine has to melt powders (metal, plastic, etc.), it uses an IR laser. When a 3D printer needs to cure resin (photopolymers), it relies on a UV laser.

Vat (Reservoir)

A reservoir is a box where the raw 3D printing material is added. It can be used for powders and resin.

Chamber

Resin and powder-based 3D printers are fully enclosed. They have a special chamber inside which a model is built.

Most of the 3D printer hardware, a build plate, laser, galvo scanner, or other elements could be inside the chamber. An enclosed machine also has a ventilation system for odours, excess heat, etc.

Elevator

This part of a 3D printer is responsible for lowing and raising the build platform where a model is 3D printed.

Since the 3D printing process creates objects layer by layer, an elevator travels up and down after every layer is laid.

P.S. Some 3D printers also include overflow bins (for excess material); a roller that moves 3D printing material over the bed surface; a temperature sensor, and other elements.

Besides, 3D printer basics must mention data input (a 3D printer communicates with a computer, USB or SD card to “read” 3D model and transform digital information into a physical process); source files (STL, OBJ, others) and a finished 3D print (model, object, part).

3D Printing Applications

The development of 3D printing and the popularity of this innovative technology enables different industries to profit from it. It is now possible to apply additive manufacturing in medicine, aerospace, education, the automotive industry, etc.

3DP technologies help reduce logistical expenses because companies can create local production units instead of getting their supplies from one big factory. It could lead to lowing transportation and production costs and provide more opportunities for multinational businesses.

Besides, 3D printing could make the customisation of products a breeze. Although now its most popular applications are prototyping and product development across industries. But more significant changes are yet to come as the AM processes continue improving and introducing themselves to more and more consumers.

Aerospace

3D printing has been used in aerospace for many years thanks to the precise results and quick production time. This industry is one of the first adopters of the expensive 3DP technology. It benefits from applying it in prototyping and development.

Many aerospace companies helped to push the boundaries of AM through R&D (research and production). For example, Boeing, Rolls-Royce, GE Aviation and other giants understand well that R&D is a critical element of innovation. Still, aerospace uses 3D printing to recreate complex lightweight aircraft parts and develop some space projects.

Medicine (Dental Industry)

3D printing found its applications in the healthcare field. Medical organisations and the dental industry take full advantage of advanced technologies, research, and develop innovative solutions.

Just like in the aerospace industry, 3D printing applications in medicine found their way in the early stages of AM development. Thanks to 3D printers, medicine can personalise and customise materials, help people live a better life and ensure that 3D prints meet high medical standards.

Where to 3D print in medical and dental industries? The list of possible applications amazes everyone. The AM technology makes it easy to make prototypes, medical tools, dental aligners, casting a dental crown, etc. Besides, hospitals use 3D printing processes to make implants, shoe orthotic insoles, customised prosthetics, unique products specific to each patient.

Moreover, 3D printing has the potential of recreating bones, human skin, tissue, organs and more! Of course, it could take years to make this a reality, but anything seems possible.

3D Printing in Manufacturing

The precise details, quick speeds and 3D printing fabrication make AM technology super attractive for the manufacturing industry.

In the early days of 3D printing development, this process was too expensive to employ in factories and manufacturers. But the more affordable 3D printers become, the more businesses can take full advantage of using them to design new products, create moulds, and improve the development cycle.

If earlier manufacturing processes required designers to think about how to create an object to make its assembly accurate, 3D printing makes it simple. You can design even the most complex things because a 3D printer can print anything. Thus, there are more ways for the application of AM technology in factories. And as 3DP keeps developing, it will offer even more incredible benefits and endless opportunities for businesses.

Automotive Industry

Today, 3D printing applications in the automotive industry have not reached mass production in markets worldwide. But AM technology is already employed by different companies that 3D print vehicle parts and use 3D printing for developing engines and design verification.

The automotive industry still prefers prototyping applications, but it uses 3D printing for creating lightweight and complex car parts and engine elements for luxury and sports cars.

Car repair shops also use 3D printers to improve their everyday services. The innovative technology helps to repair old cars instead of recycling or dumping them into landfills. Even if a manufacturer stops producing supplies and spare parts for older vehicles, a 3D printer can print any part. Besides, it is cheaper to 3D print on demand than stock all existing parts you might never need.

Education

The educational sector can also benefit from 3D printing technologies. Art schools, physics, mathematics and other disciplines can use 3D printers to visualise different geometries and designs.

It is also possible to 3D print elements for musical equipment, parts for educational research and other disciplines of study.

Defence

The 3D printing applications in the defence industry found numerous ways of realisation. Militaries can use 3D printers to build obsolete parts on-demand, create tools, fix ship hulls in the sea. It is possible to 3D print military vehicles, make replacement parts for techniques and bunkers, etc.

Having a portable 3D printing factory becomes important for different armed forces. It is much quicker to 3D print parts at the frontline and field than ship essential replacement parts. It is simpler to recreate important yet light aircraft parts, engines for tanks, submarines and surveillance equipment.

The AM technologies help cut costs, simplify the supply chain, introduce innovation and bring the ready-to-use manufacturing process to all soldiers and every defence branch.

Architecture

Architects love applying innovative technologies such as 3D CAD, various design software, and now 3D printing. The AM process has become common in big and small companies that build houses and offer architectural services.

The 3D printing applications in architecture started from standard building layouts, structure verification, advanced scaled modelling and grew into constructing physical bridges, houses, and other architectural forms. Giant 3D printers can build nearly anything!

Fashion

This industry loves experiments like no one else. Fashion uses 3D printing for numerous things. It has become accessible to 3D print shoes, hair accessories, bags, hats, outrageous outfits and more.

Hobbyists and professional fashion designers use modern technologies to create one-of-a-kind dresses, fantasy gowns, Halloween costumes, masks, helmets, even underwear! These days, we even see 3D printed elements and couture designs on catwalks in Milan, Paris and other countries.

Food

Several years ago, it was hard to imagine 3D printing applications in the food industry. But today, it is the reality. As technologies develop and improve, more companies explore the potential of AM processes and implement innovations.

The ability to 3D print real food excites both companies and ordinary people. This option is not standard yet. Still, many people have heard about it, and some have even tasted the 3D printed products.

It all began with 3D printing sugar and chocolate meals. Later the industry tried to 3D print meat and pasta. The introduction of specific printers gives new ways for experiments. Thus, healthy and balanced food fully 3D printed could be just around the corner.

Jewellery

Another sector that can take advantage of 3D printing applications is jewellery. In older times, the creation of jewellery required specific skills and knowledge. The whole process was time-consuming because the manufacturing of every piece required moulds, casting, stone cutting, material smithing, engraving, etc.

A 3D printer simplifies everything. While it is still an expensive machine if you work with gold, silver or other metals, the process can eliminate several steps in the original production. Thus, more companies and small jewellery businesses think of the benefits of getting a precise 3D printer.

Where Can I Use a 3D Printer?

The variety of affordable desktop 3D printers makes hobbyists and enthusiasts from all over the world employ the new technology at home.

With a 3D printer, you can make sculptures, recreate your favourite movie and video game characters, toys, collectable figures, comics miniatures and other creative ideas.

Besides, you can repair old things in your home without the need to throw things away just because one part is missing. For instance, you can 3D print a battery cover for your remote control, make door stoppers, vases, home decor, holiday ornaments, etc.

3D Printer Beginner Guide

Personal desktop 3D printers are becoming more and more popular as their prices significantly decrease year after year. Our guide to 3D printing for beginners will help you select your first machine. You will understand the process of 3D digital printing from the moment you buy a 3D printer to the moment you complete your first 3D print.

The prices on a desktop 3D printer for beginners range from $100 to thousands of dollars. Thus, anyone who wishes to dive into the world of 3 dimensional print masterpieces has a chance.

A personal machine is excellent for engineers, individuals and small companies that wish to train while designing for AM or have a fantastic hobby and hours of self-entertaining during weekends and evenings. A user-friendly 3D printing tutorial for beginners will come in handy when ready for the AM projects.

Intro to 3D Printing

Let this intro to 3D printing begin with understanding your requirements for the machine, software, post-processing and finishing of the models. You should take an important decision so that your beginner 3D prints amaze you and give you many moments of enjoyment.

Before getting deeper into the guide to 3D printing, it is best to quickly outline the process of using a 3D printer from scratch. Such an intro sketches what you are about to deal with.

Step 1: What to 3D Print

Any project begins with an idea. Thus, you must think about valuable things to 3D print or choose the home decoration, an impressive cosplay costume or a figurine from a cartoon or movie.

When you only begin to understand 3D printing, you are highly advised to choose simple 3D printer projects for beginners. You can start testing by making a simple cube, Benchy boat 3D model and similar things. After this, you will prepare for more complex shapes and move on to creating fantastic figurines and models with numerous assembly parts.

Step 2: Beginner 3D Prints

You can design a 3D model yourself in CAD or non-CAD software. Or find a project already sculpted or modelled by someone else.

It is worth noting that designing a model for 3D printing is not the most straightforward task. It takes time to learn the skills and practice to sharpen them.

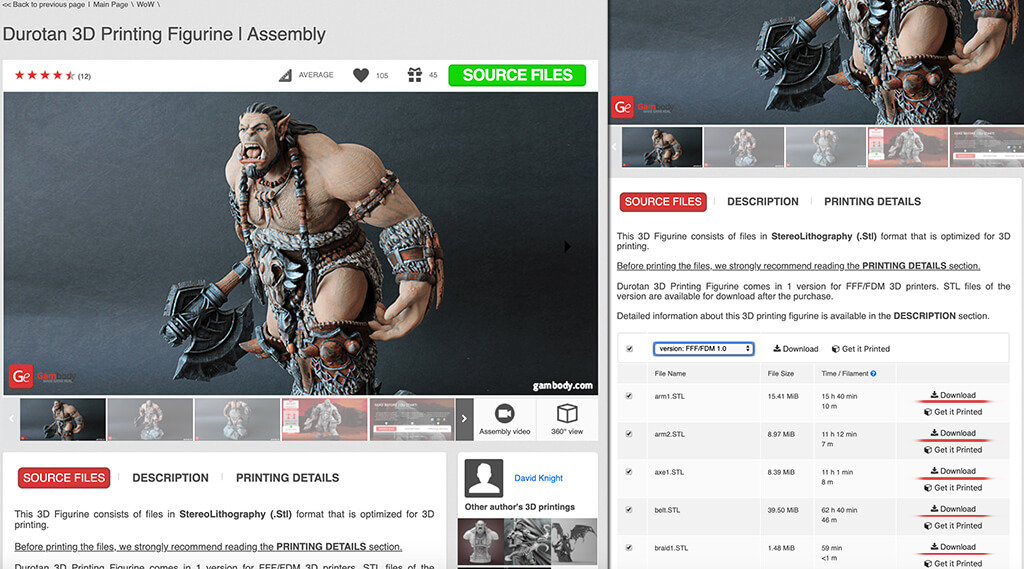

Every 3D model must be converted into STL format to prepare for 3D printing. The best thing for a beginner is to find a project in STL format, such as figurines from gambody.com marketplace. Gambody files are already checked for errors and come with 3D printing instructions and settings you can use.

Step 3: G-Code Files

Learning 3D printing also requires learning slicers. It is essential to use slicer software to cut the model into layers for the 3D printer to “read” to build the parts.

You will save your sliced up object as a G-code file. Your machine will easily recognize it and start 3D digital printing.

Summing up the intro to 3D printing, you should find or design a 3D model, convert the project into STL files, slice it up and save it as G-code for a 3D printer to understand.

How to Choose Your First 3D Printer

Learning 3D printing is now possible even if you are a housewife. The times when AM was used for prototyping are gone. Nowadays, knowing what’s a 3D printer is a must for hobbyists and small companies because this technology can change lives.

Understanding 3D printing gives advantages to users who can create designs and produce products on their own. So, if you have a creative mind, you should empower your ideas with the right 3D printer. When choosing your first machine, the question arises of what to pay attention to. And our beginner 3D printing tutorial is aimed to guide you.

What is your skill level?

A 3D printer for beginners should comply with your skill level. A home machine can be a hobby printer or a mini-factory for producing market-aimed products.

Depending on your ideas on using a 3D printer, you can get an affordable machine under $300 or buy a more professional device under $1,000 or above this price.

3D Printer for Beginners (Fully Assembled)

Many affordable machines come fully assembled and ready-to-3D-print right out of the box. These 3D printers boast some excellent features, so even a beginner can adjust the settings, “feel” the machine and make it build some stunning 3D prints.

3D Printer Kit

Some machines are offered as kits. You will receive several parts and instructions on assembling and using a 3D printer. Every enthusiast wishing to learn how to use a 3D printer will be happy to know it well from the inside.

Build Your 3D Printer

Advanced users can have fun building an incredible machine from scratch. Such a project will need good programming skills, electronic knowledge and mechanical mastery. It could be pretty expensive and time-consuming, but it will surely be worth your effort.

What are your plans?

After reading about different 3D printing applications, you should decide what you plan to make with a printer.

Your intentions mean a lot because the price of a 3D printer for beginner and advanced users differs significantly.

“3D Printing” as a Hobby

Enthusiasts who wish to start 3D printing for personal needs (as a hobby) and do not plan to build a business with 3D printers might not need a costly 3D printer. Affordable machines under $500 offer many incredible opportunities and can serve well at home.

As a hobby, 3D printing can offer you many stunning ideas:

- Things to decorate your house (vases, dishes, cups, bowls);

- Replacement parts for your household goods (doorknobs, door stoppers, faucet water-saving parts, etc.);

- Toys to make your kids happy (unique puzzles, 3D printed cars, figurines from cartoons and movies);

- Life-like figures to add to your collection;

- Furniture pieces (shelves with secret chambers, table legs, chair wheels, etc.).

No matter what you are planning to 3D print as a beginner, you will have a lot of fun!

Read also: Over 100 Fun 3D Printer Projects

Prototyping and Concepts

Small and large businesses can also use “3D printing” in their projects. Because of the endless possibilities, learning 3D printing is now a must for everyone who wants to benefit financially and save much time and nerves.

Making various plastic things is a quick and cheap option available to many. Your 3 dimensional print can cost you about 3 cents per gram. Is it suitable for prototyping? Absolutely! And such beginner 3D prints can be super fast and let you experiment, learn, improve your skills and create new, amazingly innovative items.

With many instructions on how to use a 3D printer, you can find details on profiting from nearly every machine that enters the market. Thanks to enthusiasts and hobbyists worldwide, you can learn to set up your device, adjust its speed, discuss your projects on forums, etc.

Explore the 3D printing diagram to understand how different types of 3D printers work, and then choose your machine. Use it to create concepts and prototypes to enhance your business. Such a solution is way cheaper and faster than the normal development and manufacturing of a new product.

Visualizing the end product via 3D digital printing is becoming more common now. This method can be used for creating new toys, shoes, stationery items, tools, decor pieces, furniture and other things. Understanding 3D printing can help you evaluate your designs, think of the functional changes and specifications needed and save money on approving the final product to become mass-produced.

3D Printer Beginner Guide

When you are searching for a 3D printing tutorial for beginners, you will come across advice on how to choose your first 3D printer. So, what should you consider when buying a resin or FDM machine?

The main factors to assume are the comfort of using a 3D printer (specs), its price, printing size, type of 3D printing material (filament or resin), customer service and reviews of other hobbyists.

3D Printer Price

You can build beginner 3D prints on a cheap 3D printer. The price matters a lot to every newbie. Sit and think about how much you can spend on “3D printing”, and then look at the reviews of 3D printers within your budget.

Cost depends a lot on the specifications of a machine and the comfort of using a 3D printer. A device under $200 will not offer the same features as the machine for about $1000.

Still, the lowest FDM 3D printer price of slightly over $100, $200 and $300 can attract new hobbyists whose intro to 3D printing can begin with low-cost machines. But pay attention to the type of filament the cheap device supports because while learning, you will most likely mess up some projects and waste some filament. Thus, it is best to learn 3D printing using inexpensive 3D printing materials.

Specs

Depending on your budget, you can choose the specifications that suit your interests and needs. These are some of the things that can make the price go up, but they do make the use of a 3D printer more comfortable:

- Filament auto-feeding;

- Auto-levelling;

- Resume printing after pause or power outage;

- Removable magnetic platform;

- Fully-assembled machine (ready to print out of the box);

- Heating bed;

- Support of various 3D printing materials (FDM machines);

- Support of offline printing;

- Support of different Slicer software;

- Stable metallic frame;

- Big build plate (volume).

When you learn what’s a 3D printer, you can explore its specifications and think of which options are must-haves and which features you don’t need. Then, you can create beginner 3D prints, test the machine and gain experience. With time, as you go through each new 3D printing tutorial, you can grow your collection of devices to more than one.

Printing Volume

The size of the platform often matters a lot while you are working on your 3 dimensional prints.

Bigger platforms usually cost more, but they also allow for making life-size and giant beginner 3D prints. However, these days you can find some user-friendly cheap 3D printers with a large bed size that could lack some other specifications but do let you build big objects at home.

Smaller beds are good for making 3D printed miniatures and small collectable figurines of your favourite superheroes and video game characters.

Type of 3D Printing Material

While reading the 3D printing tutorial for beginners, you will learn about different 3D printing materials.

If you choose to get an FDM 3D printer for beginners, you will likely start using PLA and ABS filaments. Other known types are Nylon, PETG, TPU, TPE, HIPS, Wood, colour-changing plastic blend, glow-in-the-dark and different types of plastic.

Most FDM machines can use more than one type of filament for 3D printing (one spool usually costs about $30-$50). Only a small number of devices is limited to using its brand-owned type.

Suppose you select a resin (SLA) machine. In that case, you must cure your 3D printed parts yourself or via an additional device.

Performance, Speed, Accuracy

Since you already know what is 3D printing used for, you might wonder how to choose your first 3D printer. After deciding on the budget and type of machine, you can start exploring the device’s performance, speed and accuracy.

When you regularly start using a 3D printer, you will understand how fast printing speed, excellent accuracy, and high-performance matter. It helps to save some energy, time and money. It also makes it easier to achieve incredible results and be proud of your project.

Also, pay attention to the price of the 3D printer parts. Usually, a manufacturer or 3D printing marketplaces with STL files let you calculate the estimates of filament (or resin) you might need. Besides, you can join Gambody 3D Printing Community on Facebook, where hobbyists share details on how much material this or that 3D print requires.

Every 3D printing diagram will show you that resin projects are usually way more accurate and detailed than FDM items. But every popular method has its pros and cons, which you should consider.

Customer Service

Learning how to use a 3D printer is not that difficult, no matter which machine you choose. Thanks to the internet, finding the best 3D printing tutorial for beginners is easy and quick. What matters more is the customer support provided by the machine manufacturer.

While working on your beginner 3D prints and improving your skills, you might come across some issues with a 3D printer. Only good customer support will be ready to assist you, give you advice, ship replacement parts, etc.

The fantastic news is that most companies that make desktop 3D printers offer lifetime support and are willing to help when needed.

3D Printer Reviews

Your personal intro to 3D printing can begin with understanding the process and reading reviews on different machines.

Customers unhappy with the purchase leave reviews more often than users who encounter no issues. But thanks to negative reviews, you can learn whether the 3D printer has many common problems or not. Depending on the bad/good points, you can make your choice.

You can google the first 3D printer you wish to get, visit the official manufacturer websites, Reddit, Yahoo Answers and other trusted review sites.

Please remember that your 3D digital printing experience depends on your skills. Practice makes miracles, so learn how to use a 3D printer, select your first machine and don’t be afraid to create beginner 3D prints.

Use a 3D printing tutorial for beginners for several simple 3D printed models. Your understanding of the process will quickly impress you.

Questions About 3D Printing

There are so many questions about 3D printing that it is impossible to answer all of them by recollecting the history of this technology, its processes, popular 3D software and tips for choosing your first 3D printer.

Thus, Gambody wants to compile a special “3D Printing 101 Questions” chapter with answers many beginners will find useful. We will update this list to ensure it is the most comprehensive guide covering all the common questions that come to your mind after you obtain a 3D printer. It explains all the steps you have to take to 3D print a model of your choice right away.

- What is the type of my 3D printer?

- When can I download STL files for the 3D printing model purchased on Gambody?

- What version of files from the “Source Files” tab do I need?

- What is the difference between multiple versions of STL files?

- Why one small model has so many STL files?

- Do I simply save STL files on SD card and insert it into a 3D printer?

- Why use slicer software before 3D printing anything?

- Why are supports used in 3D printing?

- Can I scale the 3D printing model myself?

- Where to search for simple models for beginners?

1. What is the type of my 3D printer?

Each 3D printer runs its 3d-printing kind of process. It uses a particular material extrusion technique. You can learn all the details about the nine main types of 3D printers on Gambody blog, or shortly understand which 3d printer you have from this 3D printing guide for beginners.

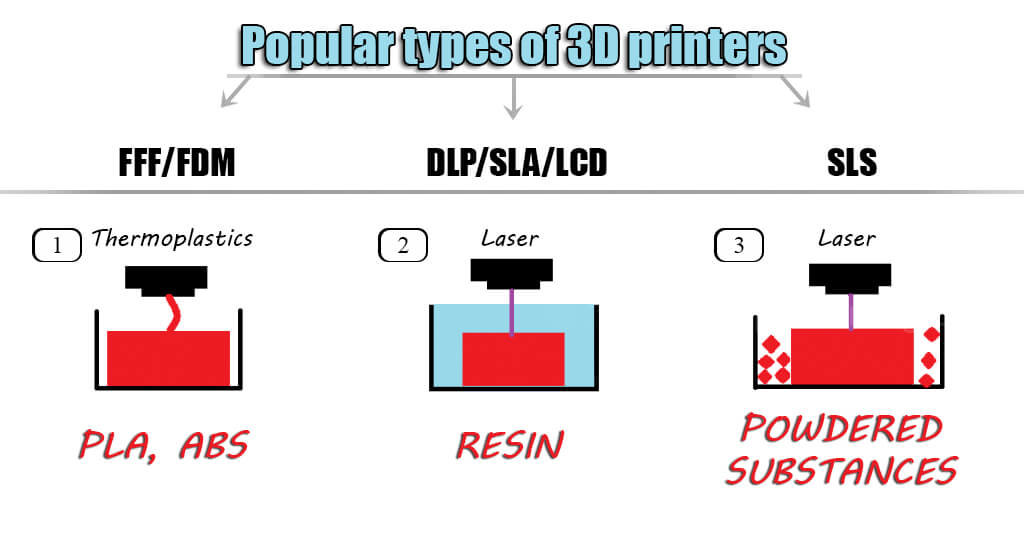

The most popular types of 3D printers are:

- FFF/FDM – extrude thermoplastics (PLA, ABS) through the nozzle to the print bed, building a model layer by layer.

- DLP/SLA/LCD – work with liquid plastic (Resin) shaping it with a light source to produce solid layers.

- SLS – work with powdered substances (Nylon, Metals, Ceramics) forming a model with a laser.

Less common types of 3D printers are SLM, EBM, LOM, BJ/MJ.

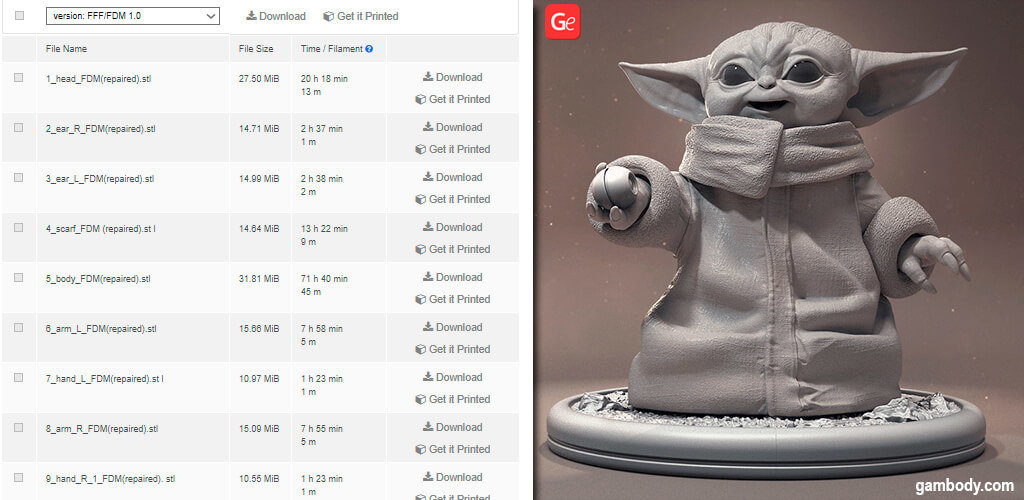

2. When can I download STL files for the 3D printing model purchased on Gambody?

Once you purchase any 3D printing model on Gambody marketplace, you immediately receive access to its STL files. You can freely download all versions of which that the model is comprised from the “Source files” tab on any model’s page.

This access remains granted to you as long as your Gambody account is active.

3. What version of files from the “Source Files” tab do I need?

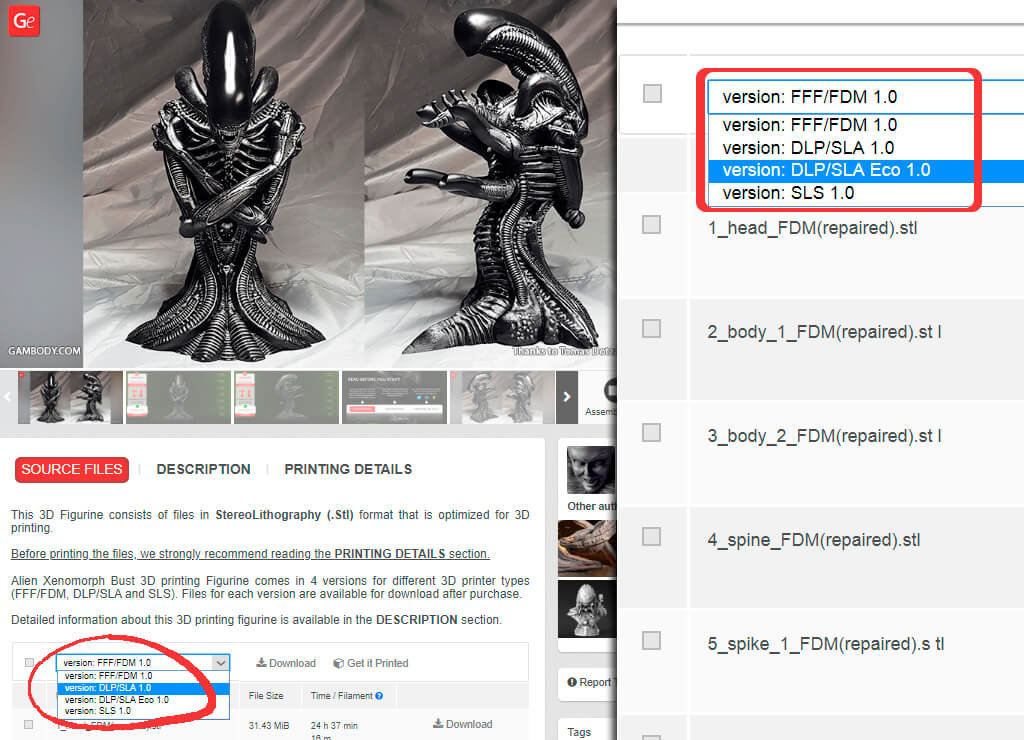

Gambody marketplace offers several versions of each 3D printing model. You need to download the version of STL files from the “Source Files” tab that was adapted and optimized for your 3D printer type.

Follow this 3D printing guide for beginners to get the correct files:

- If you have FFF or FDM 3D printer and print with ABS or PLA filament, you should download the FFF/FDM version of STL files.

- If you have DLP, LCD or SLA 3D printer and print using Resin, you should download DLP/SLA or DLP/SLA Eco version of STL files.

- If you have SLS 3D printer, you should download SLS version of STL files.

4. What is the difference between multiple versions of STL files?

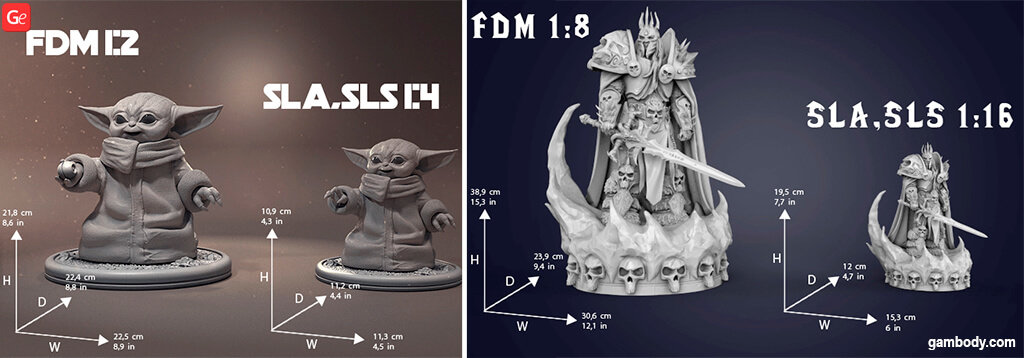

Several versions of STL files for the same 3D printing model take into account the practical aspects of building the project on particular types of 3D printer. Gambody team makes sure that the chosen scale of the model and the number of cut parts guarantee the best printing result.

For example, FFF/FDM version of STL files is usually bigger because ABS or PLA filament is more affordable than other printing materials. Besides, FFF/FDM printers craft clean and detailed models when they are printed at a larger scale, and it is more interesting to paint such bigger projects.

At the same time, DLP/SLA versions of STL files are twice less in size than FFF/FDM version. Smaller size can save the expensive Resin material and consider the smaller build plate of DLP/SLA/LCD 3D printers. Resin printers are great at building little details, and they deliver excellent results when making a smaller-scale model.

DLP/SLA Eco versions of STL files come with hollowed out parts of the model. Hollow models intend to keep the printing costs down and save even more Resin than regular DLP/SLA versions.

5. Why one small model has so many STL files?

Each 3D printer has a limited print bed. Besides, every user likes to position 3D printing model in his way. Thus, Gambody team makes sure to cut every FFF/FDM and DLP/SLA project into several STL files, to make the 3D printing experience as smooth as possible.

Each STL file makes it possible to 3D print an error-free part of the model, save printing time and material, and use as little supports as possible. Then all the 3D printed pieces can be assembled or glued together, transforming into a finished product.

SLS versions usually contain a one-piece model (figurine). Sometimes it comes with two pieces, a platform and one-piece figurine which can be detached from the platform.

6. Do I simply save STL files on SD card and insert it into a 3D printer?

No, 3D printers do not support STL files. The STL files adapted for your 3D printer must be converted into a G-code. This G-code file must be saved on the SD card and inserted into a 3D printer to craft the project.

The G-code file is generated in slicing software (computer software that supports Windows/Mac machines).

7. Why use slicer software before 3D printing anything?

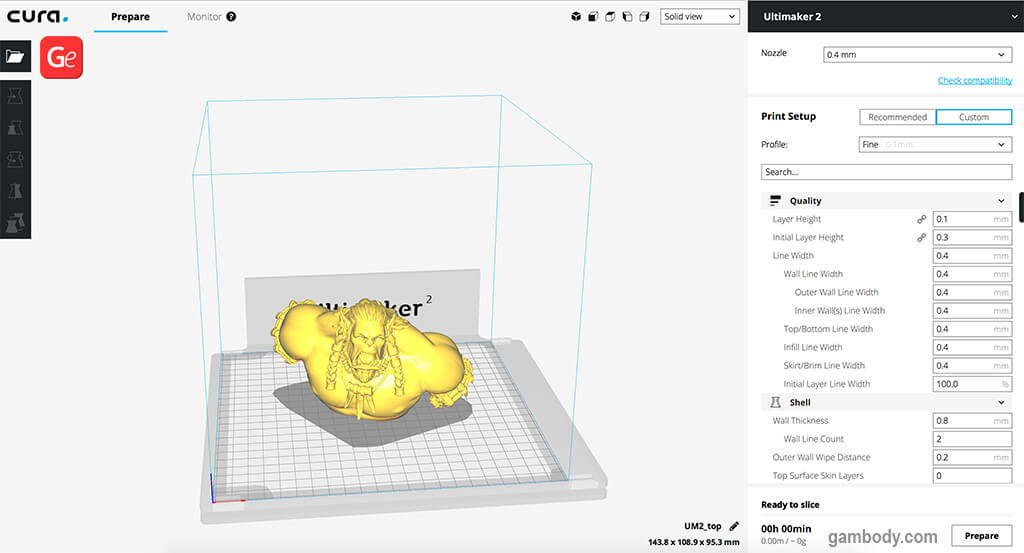

Slice software is vital to use when it comes to the conversion of the STL files into a G-code, which is supported by a 3D printer.

Each 3D printing model’s page on Gambody marketplace shows a list of printing recommendations in the “Printing details” tab. It lists recommendations for the three most popular slicing software, Cura, Simplify3D and Slic3r. However, you can use other software such as PrusaSlicing, Repetier, Netfabb, Z-Suite, etc., as long as it is compatible with your type of 3D printer.

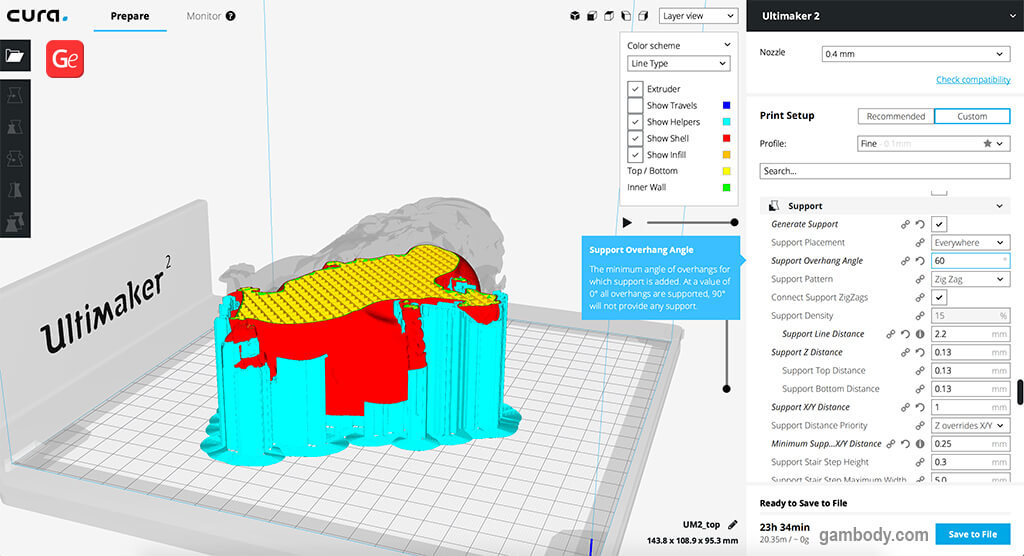

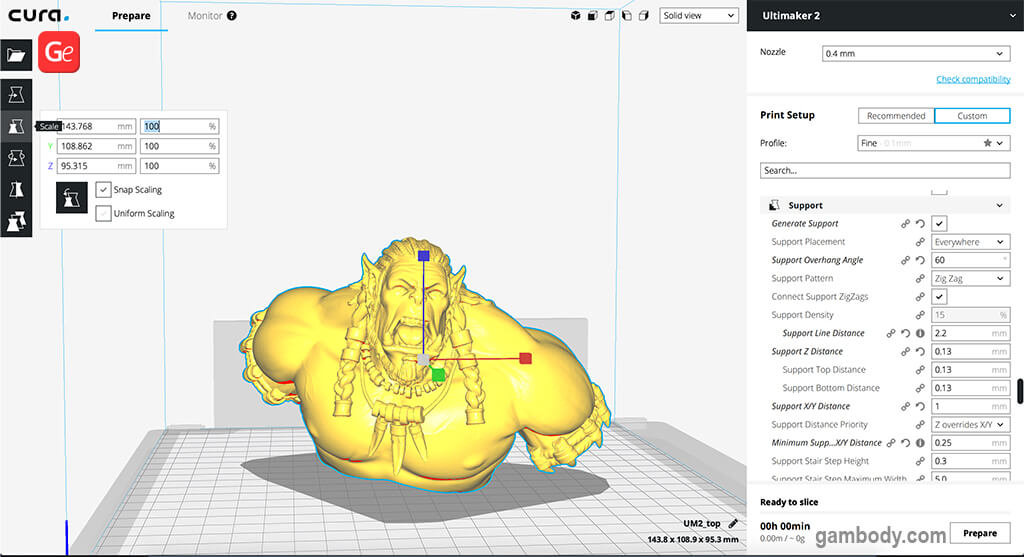

Once you choose your slicing software, you should download and install it on your computer. Slicer software is essential for creating a top-quality and impressive-looking print. Many factors affect the final result. Thus it is vital to preview each part of the 3D printing model and make adjustments if necessary.

Slicer software displays the layout of each part of the model. This way, you can take a closer look at the model, analyze whether the settings are optimal for getting the best result possible, etc. Gambody team, on the other hand, always makes sure to cut the model into the optimal number of parts for the more significant 3D printing results. But the final look depends on the settings you apply.

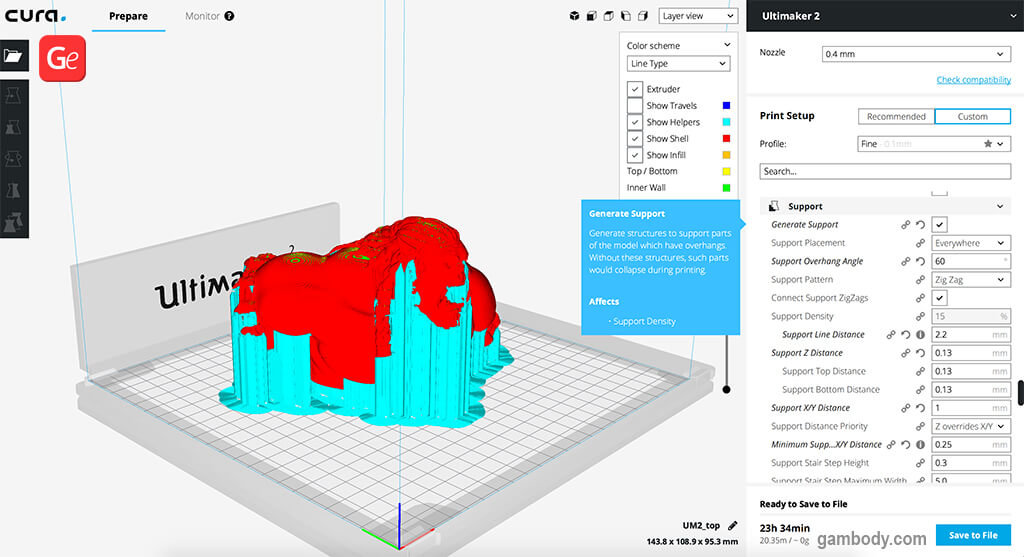

8. Why are supports used in 3D printing?

Each 3D printing model is designed without supports. Support structures are only needed to support parts of the complex model during the printing process. All supports are not a part of the model; this is why you should remove them after printing.

While there are situations when you can 3D print without supports, most models and their assembly parts require support structures.

Slicing software helps to build supports for overhangs and bridges in a 3D printing model. You can learn about the two main types of supports for beginners, simple and tree-like supports.

Models with sophisticated design have overhanging parts which float mid-air while you are printing them. The only way to prevent the model’s assembly parts from falling and failing to print correctly is to use supports. Support structures are added in slicer software, and they work like a temporary base for the overhangs which is removed after the print creation.

When you download STL files of a model you wish to 3D print, you should prepare these files for printing by launching them in slicer software. The software will show every area of the model that requires additional supports. Beginners should rely on default support settings and use the supports offered by the software. However, it is also possible to add supports manually.

9. Can I scale the 3D printing model myself?

Absolutely. Each 3D printing model offered on Gambody marketplace is very detailed. Thus, you can scale it up in slicer software without issues and print a more significant project.

Gambody usually does not recommend downscaling the models because some small details can be lost unless you are using a DLP/SLA resin 3D printer. Still, if you need to scale down the model, you can do this in any slicer software that is compatible with your 3D printer type. Just be sure to scale down each part of the project proportionally.

10. Where to search for simple models for beginners to 3D print?

Gambody team has created a compilation of the simplest 3D printing models you can turn into life on your 3D printer. Each chosen project looks fantastic and is designed for beginners.

Remember that Gambody marketplace offers the full technical support for the model you purchase. Our team is always here to answer any questions you have beyond the 3D printing guide for beginners and help you out when necessary.