Just like the internet has changed the lives of billions of people, 3D printing technology that becomes more affordable year after year changes the life of crafters, designers, and sculptors. Even an affordable FDM 3D printer for beginners lets you build a stunning figurine right at your home. But it would upset anyone to experience 3D printing issues. Luckily, our 3D printer troubleshooting guide is here to help you fix the most common 3D printing problems people encounter in 2022.

This guide focuses on FDM 3D printers only. It mentions 3D printing problems and solutions for the Fused Deposition Modelling technique, also known as FDM.

Also, learn how to prevent 3D printer fire issues from our Is It Safe to Leave a 3D Printer on Overnight guide.

Issues with 3D Printing

A list of common 3D printing problems is not known to all enthusiasts with a 3D printer at home. Some hobbyists are lucky to experience no issues with their devices. However, this strip of luck can suddenly break for no apparent reason.

Here are some of the most common 3D printing issues with FDM technology:

- Filament-related 3D printer issues;

- Blocked nozzle problem;

- Nozzle too close to the bed;

- 3D printing setup issues;

- Bad 3D prints;

- 3D print not sticking to the bed;

- Messy first layer issues;

- 3D print supports breaking;

- 3D print gaps in layers;

- 3D Benchy troubleshooting;

- Other complications that require attention.

If you face any of the mentioned unpleasant 3D printer problems and cannot complete your project on time, follow Gambody – Premium 3D Printing Marketplace 3D printing troubleshooting guide on how to solve the issues.

Read also: 20+ Photos of Epic 3D Printing Fails

3D Printer Troubleshooting

Let us say you were excited to select a fantastic 3D printing model for beginners and began to craft it on your reasonably priced 3D printer. The project starts, and you cannot wait to see the final result, but something goes wrong and you come up with 3D print errors.

The great news is you can fix some of the most common 3D print problems yourself. Follow Gambody’s 3D printing troubleshooting guide that reflects solutions to 10 problems hobbyists face most often.

1. No Filament Coming Out of Extruder

Some FDM printers display the filament reel, and you can see when you are out of filament. But some devices have these reels hidden. So, when no filament is coming out of the extruder, you start to believe that your 3D printer is broken.

Just in case, double-check your filament reel and load some fresh material if this is the case of your 3D printer problems. The fix can be straightforward.

2. Nozzle Blocked 3D Printer

If you tried to insert a new filament because your 3D printing project would not start, and nothing works, you might be facing a blocked nozzle issue. It is one of the most common 3D printing problems.

It could be possible that you left a tiny piece of filament in your nozzle while replacing spools. Even a small piece can block the nozzle and prevent the new filament from extruding.

Such issues with 3D printing often occur when you are switching from ABS to PLA all the time. You can fix it by cleaning the nozzle with a needle. It is best to do this when you heat the nozzle to the correct temperature using your computer software. Make sure not to burn your figures, and check your 3D printer troubleshooting guide from the manufacturer that comes with the device.

Read also: Best Free 3D Modeling Software 2022

3. Nozzle Too Close to Bed

These are other issues with 3D printing to be aware of. Sometimes you have loaded your filament. You start the project and are happy to observe that your print head starts to move. But nothing comes out onto the bed.

The issue can be with the nozzle which is too close to the bed. A short distance can block the way for melting filament and prevent it from extruding. Try to slightly move the position of your nozzle away from your bed, or lower the print bed a little bit. These 3D printing tips can fix your problem.

4. 3D Printing Setup Issues

Let us say you are new to 3D printing and have just configured your device. You begin to make a cute cartoon character 3D printing model, for example, but hear a horrible noise and understand that something is not right. If you see that your print head gets to the side of your device and cannot produce a print, this 3D printing troubleshooting guide is for you.

Make sure you have chosen the current 3D printer from your dropdown list in slicer software. Double-check all your settings such as print volume (the printer has to understand its exact print platform). Make sure you are running the most recent firmware version. And if this is your first device, contact the manufacturer to be sure that there is no misconfiguration on their side.

Hopefully, the problems with bad 3D prints will be solved and you will enjoy working on your 3D printing projects.

5. Print Is Not Sticking to Bed

If you notice that your project is not sticking to your print bed, you probably need 3D printing help. Our 3D printer troubleshooting instructions will quickly fix this problem.

Many users experience issues with 3D printing when a model has little contact with a platform. If everything is fine with the project you are making, then the problem can be with the platform itself.

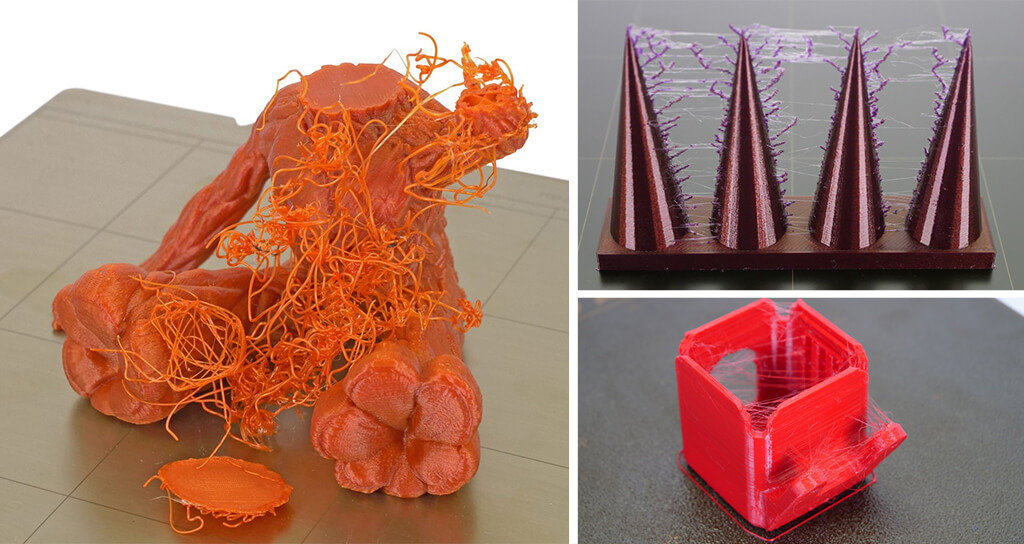

Firstly, the platform might be unleveled. You should make it even to solve these 3D print problems. Or you must adjust your nozzle height to get rid of the filament “spaghetti” bug. It is also possible to apply a layer of glue or other adhesion to the platform to help the print stick to the bed.

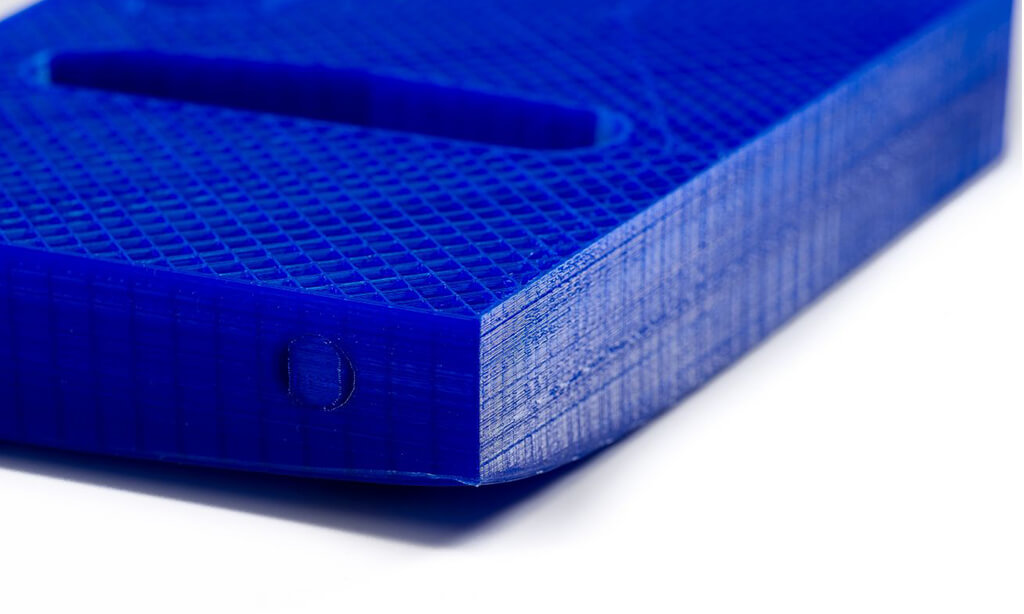

6. 3D Print Messy First Layer

One of the most common issues with 3D printing in 2022 is a problematic first layer or several layers of your print. It can happen for multiple reasons. Maybe the project cannot stick well to the platform, or the printing bed needs leveling. Or perhaps the problem is with the nozzle.

Anyways, you can follow our 3D printing troubleshooting guide to fix the problem yourself, and in many situations, you will succeed. Try to level your bed manually if your device does not support the auto-leveling option.

If this does not help, low down the temperature of the bed by a couple of degree increments. You will notice that once adhesion reaches the desired temperature, your project will nicely stick to the platform and you won’t need any 3D printing help in the future.

7. 3D Printer Failure

You are about to turn your favorite Marvel villain 3D printing model into a figurine, but the extrusion suddenly stops, and your project is screwed. In case your 3D print failed, there are several things that can help you fix such unpleasant 3D print errors.

Firstly, you should be sure that there is enough filament to complete the project. Secondly, double-check that your nozzle is not clogged. Thirdly, reread the 3D printer troubleshooting guide and instructions for your 3D printer device and search for fixes there.

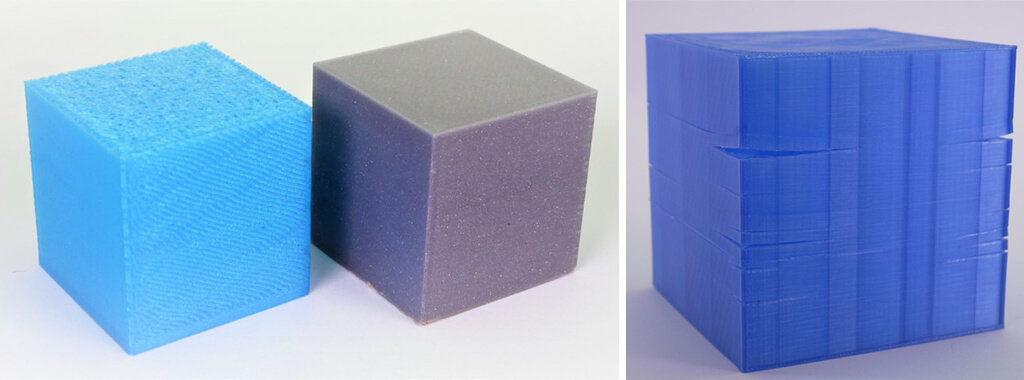

8. 3D Print Gaps in Layers

Let us imagine that you are making an outstanding World of Warcraft 3D printing character, but your project is upset with unpleasant holes between the walls and infill. Such 3D print gaps in layers and walls are among the most common 3D printing issues when you have not set the infill overlap feature in the slicing software.

You can fix the problem by adjusting the settings in the slicing program and increasing the value for the infill overlap to 25-35 percent but keeping it below 50 percent.

Sometimes issues with 3D printing can be fixed by starting to 3D print infill before your main shell is printed, or by working on lower print speeds.

Read also: Best Online 3D Printing Service for Hobbyists 2022

9. 3D Print Edges Curling

You can sometimes notice how your model’s base (first layers) is curling upwards and does not level with your bed. It does not matter if you test print 3D benchy or a different project. Our 3D benchy troubleshooting tips can help you because the problem can lead to further cracks in the model, and it is usually caused by the difference in temperatures of a cooling plastic and cold platform.

If you wish to prevent 3D print edges from curling, it is best to pre-heat your bed beforehand. Set it to a temperature that is 1-2 points below the recommended by your filament company.

If you cannot fix the 3D printing problems by playing with temperature settings, try to apply a layer of glue to your bed. When you reach a perfect adhesion, your project’s edges will stop lifting and you will thank this 3D benchy troubleshooting.

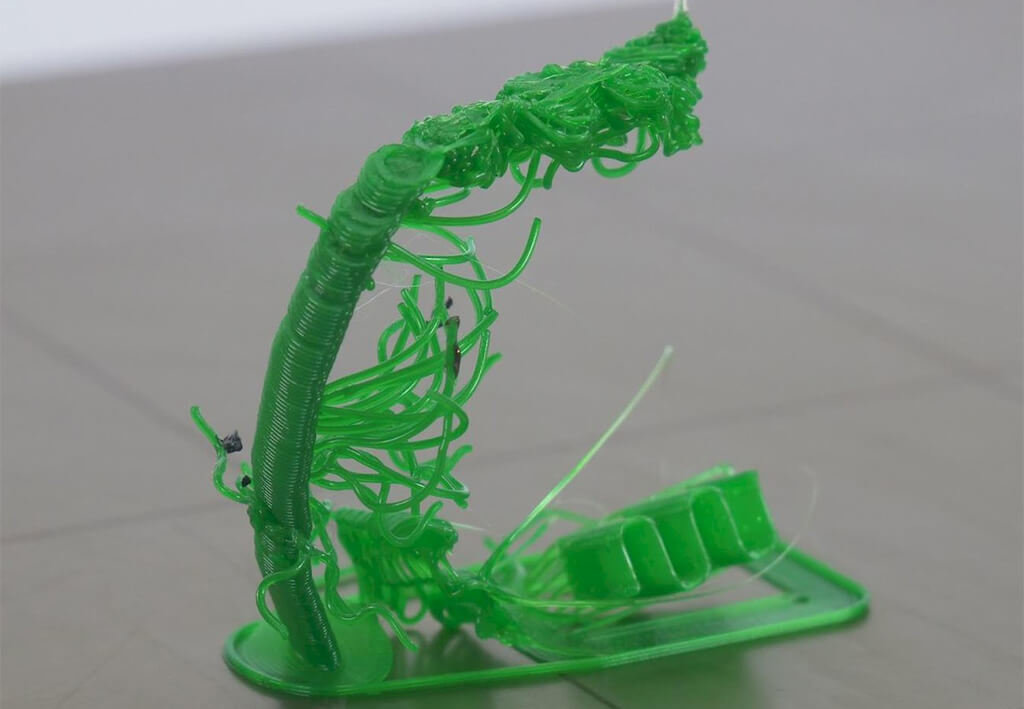

10. 3D Print Supports Breaking

When you wish to make complex 3D printing models like Halloween masks and costumes, you can experience issues with your supports falling apart. If a model that requires support is left unsupported, it will not print correctly.

Make sure you are choosing supports according to the type of your 3D printing model. For projects with overhangs, it is better to select zig-zag or line supports. If your model has minor contact with the platform, go with triangles or grids. You can also apply additional adhesion for the supports to not break them while 3D printing.

Read also: Incredible Stuff You Can Make with a 3D Printer

We hope that our list of the 10 most common 3D printing problems and solutions is handy. These 3D printer troubleshooting tips are meant to improve the quality of your figurines and statues, which you are welcome to post to Gambody Facebook Group to show your print quality, discuss errors and various issues and get help from other enthusiasts.