You don’t always need to 3D print with supports to craft incredible 3D prints. Still, many fantastic projects require these additional structures. Thus, Gambody wants you to look at the main types of 3D printing supports you can use, especially if you are a beginner and wish your figurine or statue to look professional.

Knowing how to 3D print supports also helps to avoid many common problems with 3D printers. Besides, when you select the correct type of additional structures, your model will be smoother, more comfortable to make, and quicker to remove the extras. It will also require less additional filament to save your money.

Once you discover everything you need to know about 3D print supports and patterns, it is best to learn how to 3D print without supports, discover the 45-degree rule and overhang 3D print secrets.

Table of contents:

- 3D Printing Supports;

- 3D Printer Supports Hard to Remove;

- Dissolvable Supports;

- Support Structure 3D Printing Rules;

- 3D Print with Supports: Pros & Cons.

FAQ:

- How to remove supports from 3D prints?

- How to add supports to 3D prints?

- When to use supports while 3D printing?

- What is the best support pattern in 3D printing?

- Do all 3D prints require supports?

- Why do my 3D printing supports fail?

3D Printing Supports

If you have an affordable FDM 3D printer, you will see how it deposits layer over layer of filament while at work. Layers support each other. And if there is an overhand or a bridge that lacks support below, new structures are added to lead to a great-looking 3D printed model.

Some 3D printing tips for beginners can assure you that sticking to the default settings in your slicer software is a good thing. However, such a method does not guarantee a fantastic result.

When you are not using supports in 3D printing that correspond with your model, you can come across failed overhangs and other unpleasant 3D printer issues. Thus, it is better to understand which are the main 3D printing support patterns and how they can lead to a steady, nicely supported print or bad-looking model (if misused).

Read also: Free STL Editor 2022: How to Edit and Repair STL Files

1. Linear 3D Print Supports

This 3D print support type is also called “accordion” and sometimes “lattice.” Most 3D printer beginners and professionals rely on it in the most significant number of prints.

Linear supports touch the whole underside of an overhang. They are great for angular, steep, and flat overhangs. They look like columns that grow at the platform and up to the overhang’s bottom.

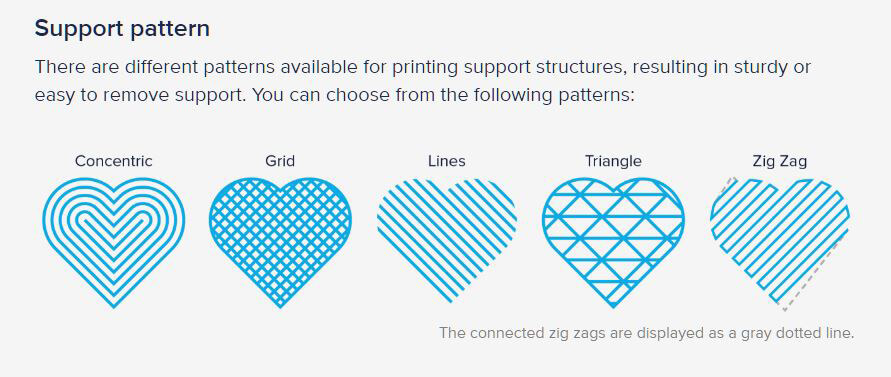

If you are using Cura software, the linear 3D printing supports will be set by default. Still, you can select between several “linear” patterns, including concentric for spheres, lines for simple shapes, zig-zag, grid, etc.

Their pros are:

- Reliable support for steep, flat, angular overhangs;

- Great support for bridges.

But they also have cons to mention. Firstly, the linear 3D printing support structures are often hard to remove because they touch the entire bottom of the bridge or overhang. Secondly, they can easily damage your 3D print surface during the removal process. Besides, they use much filament and take more time to print.

2. Tree-Like 3D Printer Supports

Models that have non-flat overhangs should use tree-like support structures. They do remind many of trees with branches. Their “trunk” grows at the print’s base, and their branches touch the overhang parts of the model at various points.

There are several pros to using tree-like supports in 3D printing:

- They are quicker and simpler to print and remove;

- They require less filament;

- They do not harm the overhangs’ underside that much.

Of course, there are also cons to consider. Tree-like structures are significant for 3D printing models that have non-flat overhangs.

If you are using Cura program, you will find tree-like structures in the “Experimental” menu. Please note that they take some time to generate, and it will be necessary to check the “tree support” box. They work great with printing fingertips, different parts of the human body that overhang, for making animals, organic shapes, etc. But they are not as reliable and stable when you use them with flat protrusions.

Here is a great video to understand the types of 3D printing support structures offered by Cura:

3D Printer Supports Hard to Remove

Regular support structures you manage via your 3D modeling software or slicer are usually made from the same material as the rest of your model. Thus, it could be a pain to remove supports from a 3D print.

You can follow these tips to ease your task:

- Do your best to first gently remove all the support structures that ease under your fingers and move with no additional tools. Try not to break anything too hard.

- You can try to carefully remove, slice, or scrap the rest of supports with a knife or a plier. Move slowly trying to leave the surface unbroken.

- If you still see the light remains of supports and wish to make the model smooth, use sandpaper of different grits and gently polish the surface.

- Often, as you get rid of supports that are hard to remove, the model is left with scratches and little holes. You can use clay, putty, or nail polish varnish to cover those minor issues.

Read also: Best Tips on How to Store 3D Printer Filament

Dissolvable Supports

These 3D printing support patterns are not typical because they are used only in dual-extruder printers. They are not available for one-extruder machines.

If you have a dual-extruder printer, you can make one nozzle to build your project in PLA filament and the other nozzle to work on supports with PVA or water-soluble filament.

Such 3D printed models are elementary to clean from the additional structures. Just soak your project into the water, and wait until the water-soluble filament dissolves.

Support Structure 3D Printing Rules

Not all bridges and overhangs in your 3D printing project require supports. There are magnificent “degree” rules to remember. They can save you much filament, time, and nerves.

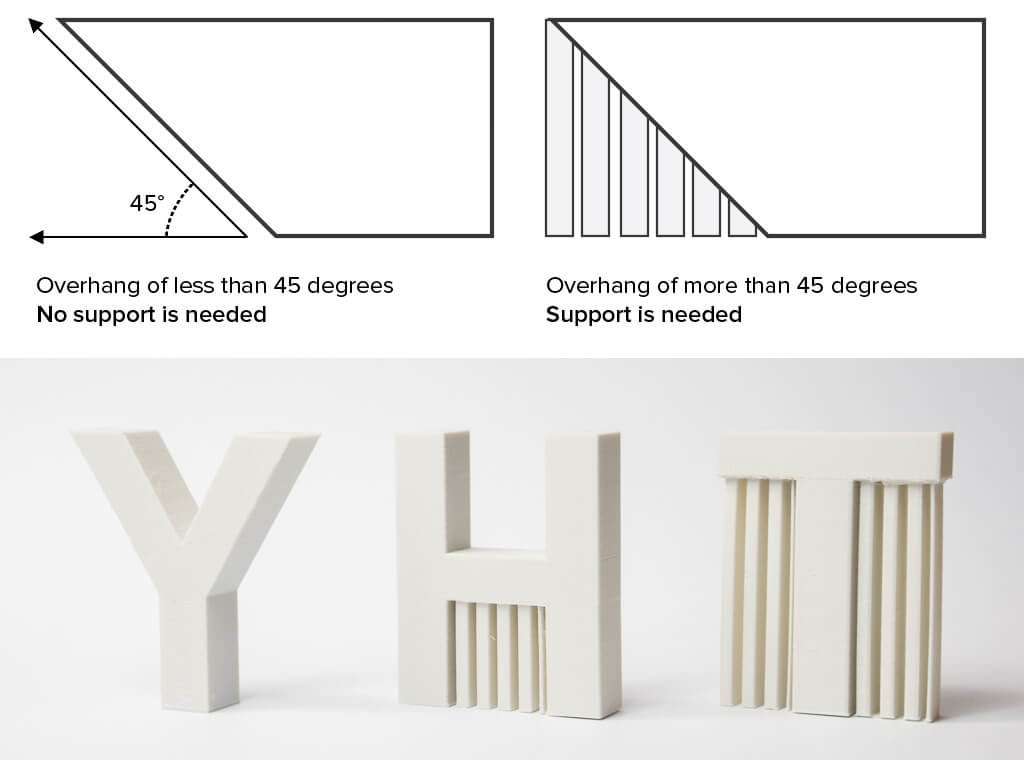

1. 45 Degree Rule for Overhangs

If your model has no overhangs that are over 45 degrees, you might need no 3D printing supports at all. It happens because the layers stack on top of each other with a small offset. It is how your machine can work with many overhangs with a fantastic result.

It is best to look at the illustration with T, H, and Y letters. They all come with overhangs. However, T and H require you to 3D print supports, and Y can be printed without these structures because its angel is under 45 degrees to the vertical line.

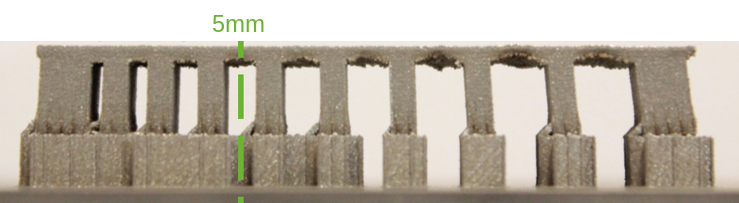

2. 5 MM Rule for Bridges

There is also an excellent rule for 3D printing bridges. It is known as the 5 mm or 0.2 inches trick. It is also simple to remember.

If your model has a tiny bridge with a length under 5 mm (0.2 inches), you can build it without adding any support structures. The modern 3D printers can stretch the hot filament for distances under 5 mm, and your project will have just a little sagging.

Of course, complex models with bridges that are 5 mm long or longer require using extra support patterns.

3. When to Use Supports in 3D Printing

No matter which 3D printer you are using, the software where you can see the model before it is actually built can show you which areas require support.

Those parts which need additional structures are usually highlighted in red. You can manually add and manage support patterns, rely on the default settings, or ask other 3D printing enthusiasts for advice.

3D Print with Supports: Pros & Cons

Even though many complicated and highly-detailed 3D models require you to 3D print them with supports, there are pros and cons to consider.

Pros of Using 3D Printing Support Patterns

Support for 3D printing can help you achieve a nicely built model with complex overhangs, holes, and bridges. Thanks to them, you can end up doing a professional-looking figurine or model you’ll be proud of.

Here are the main advantages of 3D printing with supports:

- You can bring to life a 3D model of any complexity, with bridges and severe overhangs;

- If you have a two-extruder 3D printer, you can enjoy using dissolvable supports that are fast to remove;

- Your 3D prints will look professional if you master support structure management.

Cons of Using 3D Supports

It is best to keep in mind all possible downsides of 3D printing supports. This way you can always rethink the way you position your 3D model on a bed or sculpt/model it.

These are the most common downsides of 3D printing with supports:

- Sometimes it is hard to remove supports from a 3D print;

- Adding support structure to your model makes you spend more on 3D printing material;

- It takes a long while to 3D print and remove supports from a figurine or model;

- You can damage the project while removing support structures;

- You should learn how to add and remove supports which takes time.

Gambody – Premium 3D printing marketplace, for example, recommends how to support a model before print. You can use these recommendations, or you can join Gambody community on Facebook to ask questions and get answers about the types of 3D printing supports you might need for your project.

FAQ:

How to remove supports from 3D prints?

There are two main types of 3D printing supports by how you remove them. They are break-away and dissolvable structures.

If you have a one-extruder printer, you might find 3D printing supports hard to remove because it is a must to break them away or use an additional tool (knife, plier, scraper) to cut off or scrape them.

If you have a machine with two extruders, you can use water-soluble 3D printing material for support. It could be PLA, HIPS, or something else. Such structures can be washed away in Limonene or water without issues.

How to add supports to 3D prints?

If you use Cura or another software to prepare your projects for 3D printing, you can let it generate the support patterns for you by default. Cura, for example, used to offer only linear supports until the 3.2 beta release. Starting from that version, you can choose either linear or tree-like support patterns for your models.

When to use supports while 3D printing?

Before adding support to a 3D print, evaluate it. If you see major overhangs and long bridges, you should choose 3D printing support patterns that meet your situation the best.

So, when there are unsupported areas and arches, rely on your 3D printing software and add 3D printer supports as suggested by the tool or manually.

What is the best support pattern in 3D printing?

If your project has too many non-flat overhangs, it is best to use tree-like support patterns while 3D printing. It is relatively easy to remove them and avoid damaging the well-visible surfaces of your model because such a pattern usually touches your overhangs from underneath.

If your model has many flat overhangs and severe bridges, you should use a linear support pattern. It provides good stability but is hard to remove and can damage the project’s surface.

Do all 3D prints require supports?

You don’t have to 3D print supports with every model you make. Many simple and quick projects require no support. Also, bridges shorter than 5 mm and most overhangs below 45 degrees need no support structures.

Still, a lot depends on how old and well-maintained your printer is. Some old machines fail to print overhangs at 35-40 degrees and make you always ensure you are 3D printing support structures.

Even though the 3D print supports add filament or resin costs to your project and require you to spend extra time removing the support structures, they can save your model, and make it professional-looking, and highly detailed. At the same time, supports might damage the project’s surface, so be careful when using them.

Why do my 3D printing supports fail?

Even when you follow the 45-degree and 5-mm bridge rules, your 3D printing supports may fail due numerous reasons. Your 3D model might have heavy bridges and grave overhangs, poor design, weak base. There could be issues with your 3D printer, slicer software, and 3D printing materials that warp, split, drop, curl, cause layer shifting, etc.

Sometimes it is best to test your 3D printer before working with complex projects. Find massive overhang testing models online and print them. You will learn if your machine works well with recreating 20-, 25-, 30-… 70-degree overhangs with no 3D printing supports or fails.