3D printing acquires more territory every year, so it is no surprise that this process of creating 3-dimensional objects has so many trend followers. In this post, we will cover the main 3D printing trends for 2016, with a focus on consumer 3D printers, and will list their pros and cons.

Coming a long way, 3D printing technology has recorded some magnificent achievements in different areas of human life. However, it is expected that 3D printing will get new opportunities for growth in 2016.

Metal 3D Printing

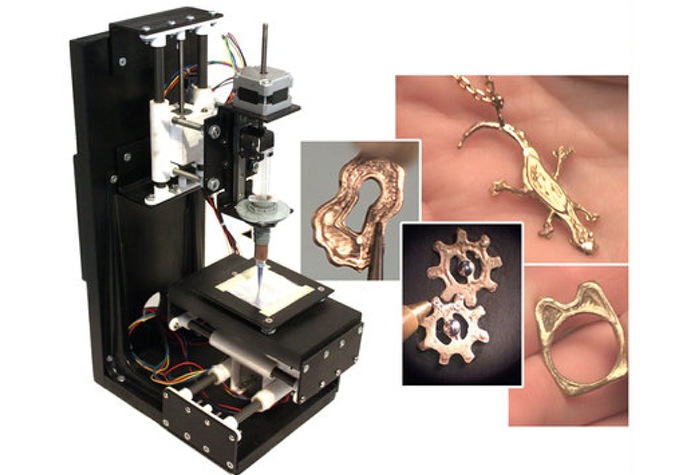

One of the most exciting things that can happen to 3D printing in 2016 is the advancement in metal printing.

It is already known that there are serious advancements in developing a home metal 3D printer. Such achievements were registered by a group of students from the Delft University of Technology. They state that they have built their own metal 3D printer.

The 3D Welder uses metal wire which is melted to bond with the metal structure. It is expected that starting this year, new 3D printers for home will be available for sale, which will be able to print in metal. This new possibility will revolutionize 3D technology. It is a big step in printing more solid and attractive models, with a more realistic look.

Currently, 3D printing technology makes use of powdered titanium, nickel, aluminum, and steel. It is considered that optimizing powdered metals for 3D printing might overcome a part of the burden and make additive manufacturing materials more cost-effective. Below you can already see how models, printed on metal 3D printers, look like.

Below you can already see how models, printed on metal 3D printers, look like.

Source: i.Materialise.com

A little sad Keanu Reeves.  Source: Shapeways.com

Source: Shapeways.com

Metal 3D Printing Technologies

Currently, there are only a few technologies that are used for metal-based printing: laser and binder jetting. Both imply a gradual and orderly extrusion of material, layer by layer, to build a predetermined object. Laser metal-based printing uses high power laser to fuse metallic powder together forming 3D shaped objects on the build platform. Binder jetting is different from other available 3D printing technologies in that it does not use heat during the printing process, thus avoiding residual stress in the parts. Also, this technology does not make use of the build plate, the object being created in the loose powder that is available in the box. It is believed that metal-based binder jetting technology is one of the most cost-effective additive manufacturing techniques.

Source: GeekyGadgets.com

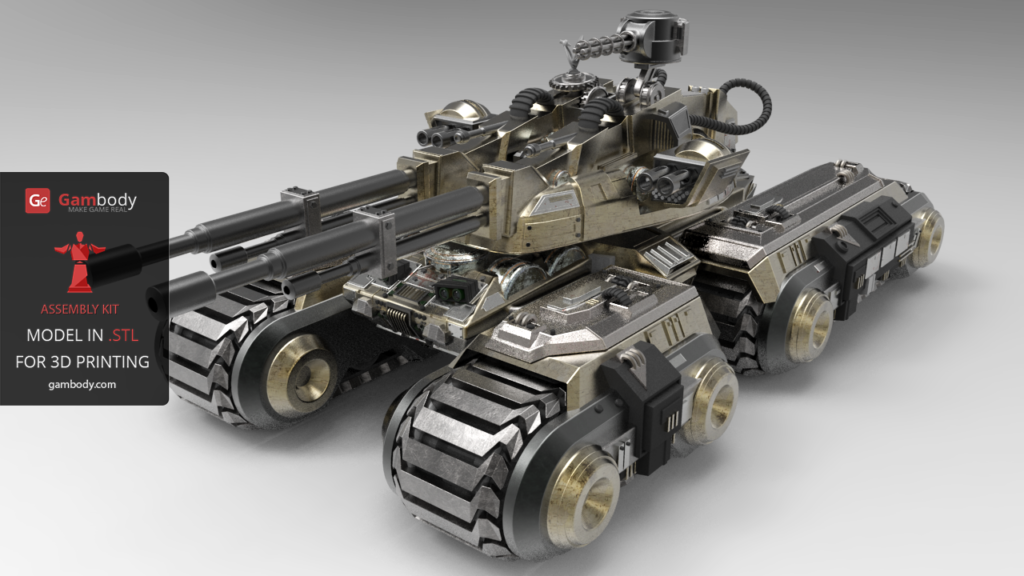

This is how the Mammoth Tank, designed by the Gambody team, would look like if printed on a metal 3D printer.

The metal-based 3D printing technology is truly here.

Pros:

- high quality of printed models;

- durability;

- wide choice range of materials (aluminum, bronze, gold, silver, and etc.).

Cons:

- high price, due to the fact that consumer-focused metal 3D printing technology development segment is still narrow;

- expensive material.

The Multicolor 3D Printing Trend

Although 3D printing has made pretty impressive advancements, printing an object in different colors and ensuring high quality of the object still remains one of the biggest challenges. Inability of 3D printers to shape an object in multiple colors is probably the one thing that keeps 3D printing success back. Even though home consumers have the opportunity to paint their printings in any color they want, people are eager to have the option of multiple color 3D printing, which will give them more freedom with 3D modeling.

Although 3D printing has made pretty impressive advancements, printing an object in different colors and ensuring high quality of the object still remains one of the biggest challenges. Inability of 3D printers to shape an object in multiple colors is probably the one thing that keeps 3D printing success back. Even though home consumers have the opportunity to paint their printings in any color they want, people are eager to have the option of multiple color 3D printing, which will give them more freedom with 3D modeling.

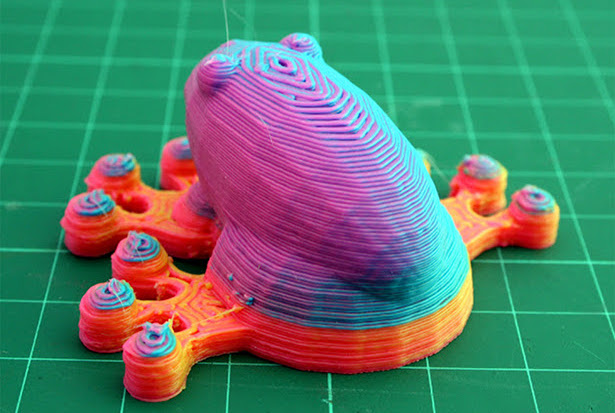

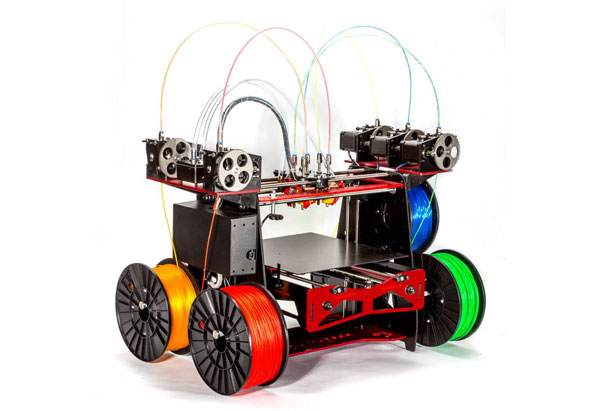

There are several methods available for multicolor printing, one of which is the Palette – a stand-alone box that can feed the multicolored filament to any monochrome 3D printer. The only thing that might be perceived as a problem is the slight increase in material use, every time the printer stops and changes color. Another method is the multicolors sandstone 3D printing. In this case, the sandstone is printed and fused together during printing process.

Source: i.Materialise.com

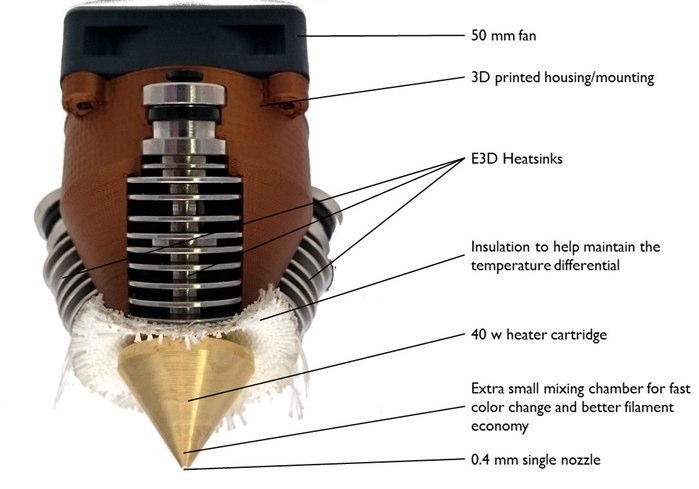

Currently, a team of 3D printing enthusiasts from Denmark developed the so-called “Diamond Hotend”, a 3D extruder that can mix and melt three filaments together and produce multiple colors. The entrepreneurs don’t want to stop here and are still in the process of developing and testing new color effects, to make multicolor 3D printing more colorful. With this new extruder, multicolor 3D printing technology will be reaching new heights.

Source: gizmag.com

Source: On 3D Printing

This is how Chaplain and TAU XV109 Y’Vahra 3D models from Warhammer 40K, designed by the Gambody team, look like when multicolor printed.

Pros:

- rainbow printing;

- limitless colors;

- simple adaptation of 3D printers to multicolor printing mode.

Cons:

- 3D printer setups;

- color solutions.

With the release of multicolor 3D printers, colorful printings become more reachable.

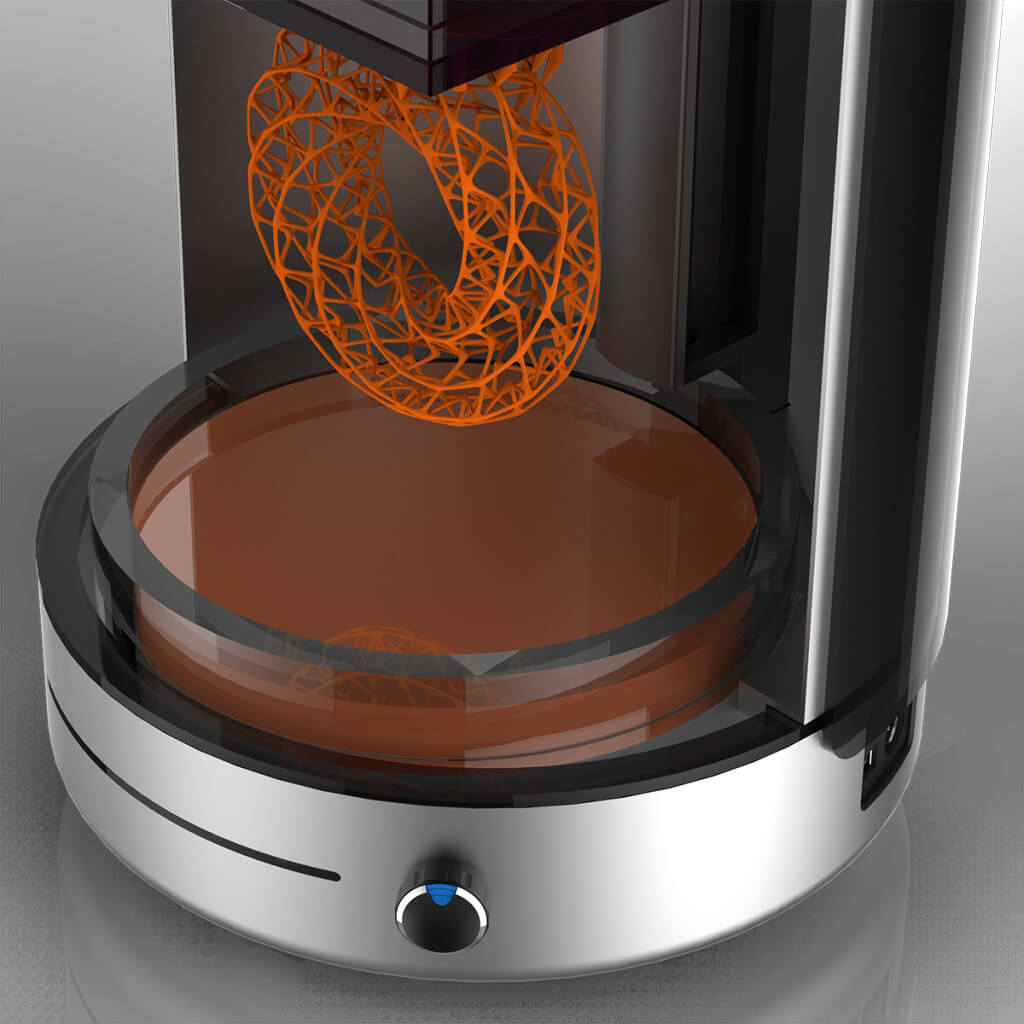

Faster 3D Printing

Time is money. Faster printing process will allow designers to test their models and parts in a shorter time and to improve or to design new patterns faster. Currently, it takes from several hours to even a couple of days (for more complex objects) to get printed out. In an age where everything is fast-forwarding, it is no surprise that 3D printing geniuses seek solutions to make the process work quicker.

Readybox 3D printer has already gained hype thanks to its ability to 3D print at an impressive speed of 400mm/s with 0.05mm layer thickness. This is probably the fastest consumer 3D printer on the market. If it is to compare the Readybox printing speed with that of the Ultimaker, which prints at a speed of 300mm/s, the difference is not that much, but you have to consider the fact that the Ultimaker developers recommend to cut the speed in half for 3D printing on their device.

Significant progress in terms of faster 3D printing has been registered by Carbon3D and HP. CLIP (Continuous Liquid Interface Production) – Carbon3D’s breakthrough technology, or Multi Jet Fusion (MJF) technique, developed by HP, are said to be from 25 to 100 faster, thus cutting considerably the production time.

Source: 3dprint.com

All the improvements made in faster 3D printing will be perceived as a relief for consumers, as they will no longer have to wait days on end to print their desired game 3D models. The gamers will print 3D large-scale models, like the AT-AT Walker designed by Gambody team, several times faster.

The faster 3D printers get, the more people will be keen to use them, thus contributing to the expansion of the market.

Pros:

- faster printing speed;

- smooth surface;

- printing of models of any complexity;

- no technical printing problems.

Cons:

- low durability of the 3D print object

- limited choice of materials (only special types of resin can be used)

- UV processing after printing, for final setting up of the material.

Conclusion

3D printing processes have made a lot of progress since they have entered the market. 2016, however, promises to be the breakthrough year for the technology, which has managed to form a large fan base, spread all around the world. These advancements will help 3D printing development to accelerate and become a trendsetter among 3D technology followers.