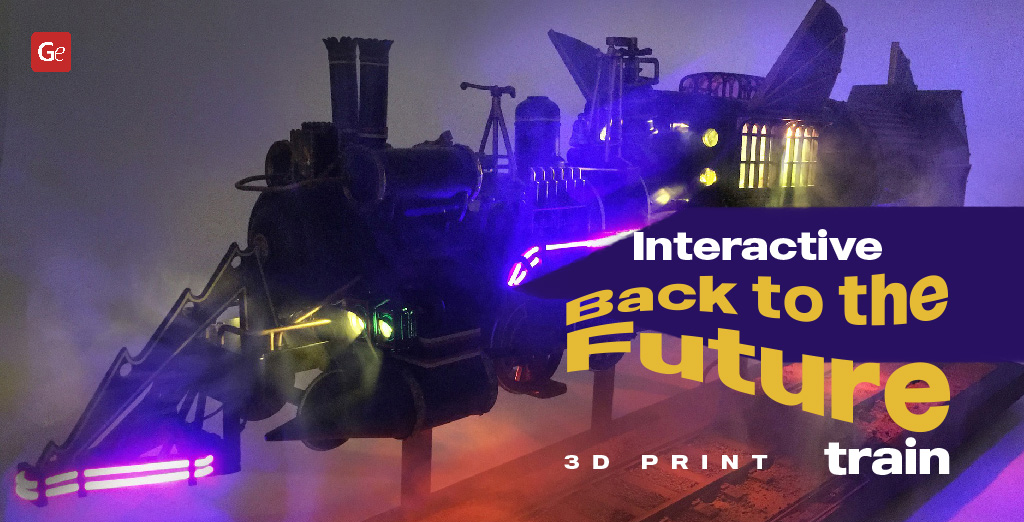

What do you do when your 3D printed DeLorean gets destroyed? Hopefully, this will never happen, but you can always become Dr. Emmett Brown and build a fantastic Back to the Future train from resin and filament. You can also add interactive elements and light up your 3D print to make it a valuable collectible, a jewel in your collection.

Enthusiast Seth has completed his BTTF train, which turned out magical, boasting a realistic railroad platform, removable wings that resemble parts of Jules Verne’s Victorian submarine, three electric motors, two smoke generators, and a lot of LED lights. Would you like to learn more about his incredible project?

Back to the Future Train: 3D Printing and Assembly Tips

The legendary time train can be yours. If you love 3D printing, explore the incredible Back to the Future STL files on Gambody marketplace and create a DeLorean 3D print (you can upgrade it with Engines, Active Suspension, Mr Fusion, as well as interior, wheels, and platforms), BTTF train, Back to the Future locomotive, and your beloved characters from science fiction films.

Your Jules Verne train can become a true masterpiece if you follow the tips shared by Seth, who spent several months redesigning and creating his own version of the legendary time train. His Back to the Future 3D print can inspire and motivate you to step beyond 3D printing and learn to redesign models, implement every idea that crosses your mind, wire the projects, add rotating elements, and have fun assembling what you have imagined yourself. Remember that “the future is what we make of it, so make it a good one!”

1. Hello, can you please introduce yourself to Gambody readers and recollect when you first learned about 3D printing and what made you fall in love with this hobby?

Hi, I’m Seth. I live in Belgium. I grew up in the 1980s as a sci-fi fan and model builder, as far back as I can remember. Back then, the toy industry was in its early stages, and many films had limited merchandising and toys. With only low-resolution VHS recordings and television broadcasts as references, a toy or model kit brought a 3D visualization of elements from my favorite films.

Back to the Future was one franchise with few toys available, especially action figures and vehicles. I remember repainting my Hot Wheels cars to resemble a DeLorean (learn how to paint and assemble a DeLorean 3D print). I’ve always loved being creative, painting, and modeling. When 3D printing emerged, I bought a machine and taught myself how to design models. After a few years of working on robotic projects, I gained expertise in electronics and mechanics. Combining my background as a graphic designer with electronics and the power of 3D printing, I started creating movie props and animated miniatures. My first project was the Luxor Cab from Back to the Future Part II, a 1/18 diecast car with 3D-printed parts, featuring four servos to fold the wheels and numerous lights. You can find many projects on my Instagram account @props_of_the_future.

First movie prop, Animatronic Luxor Cab BTTF:

2. What do you like about the Back to the Future trilogy the most?

I like a few things:

- The time travel narrative is written consistently and thoughtfully;

- The positivity of the franchise, encapsulated by the quote, “The future is what we make of it, so make it a good one;”

- Its authenticity — there was no Back to the Future Part IV. The franchise wasn’t diluted with excessive prequels or sequels.

3. How many models from the Back to the Future films have you 3D printed?

I’ve created around 20 models, including cars, buildings, and props, mostly using 3D printing and laser-cut parts.

4. What do you like the most about the Jules Verne’s Back to the Future Train design by Gambody?

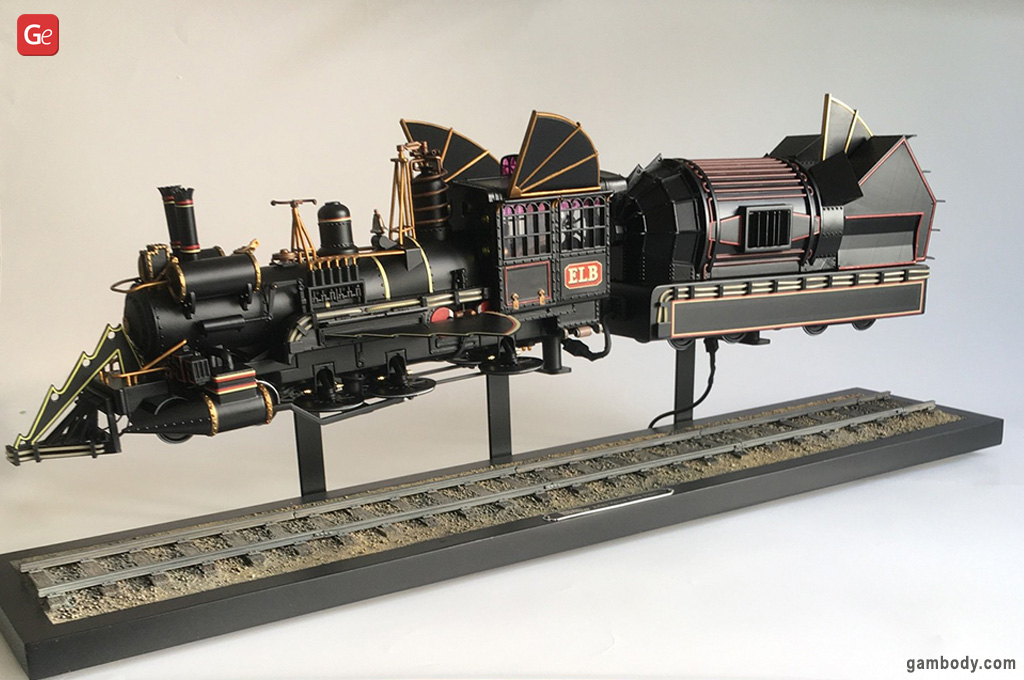

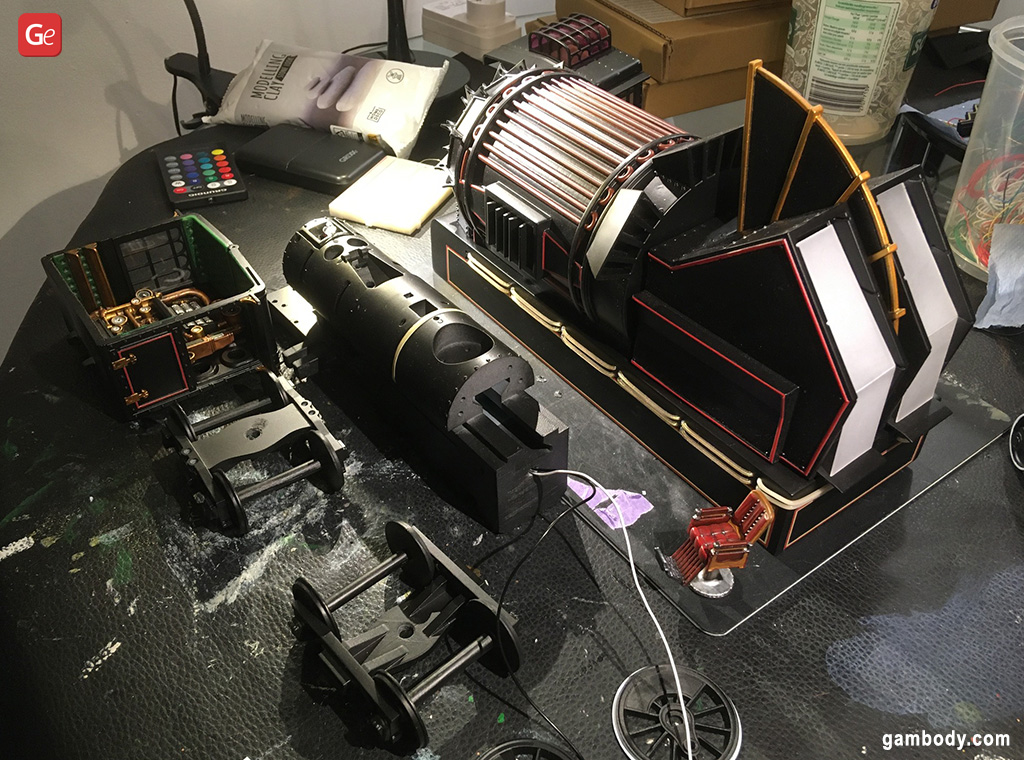

Back to the Future is rich with Easter eggs and references to culture and history. Figures like Einstein, Copernicus, Von Braun, and Jules Verne are woven into the story’s fabric. Themes of time, space, engineering, imagination, and “the power of love” create a compelling narrative. The Back to the Future train visually references the Nautilus from Twenty Thousand Leagues Under the Sea. The nose and wings of the train resemble parts of Verne’s Victorian submarine.

5. How much did you redesign this project? What needed your most attention according to your vision?

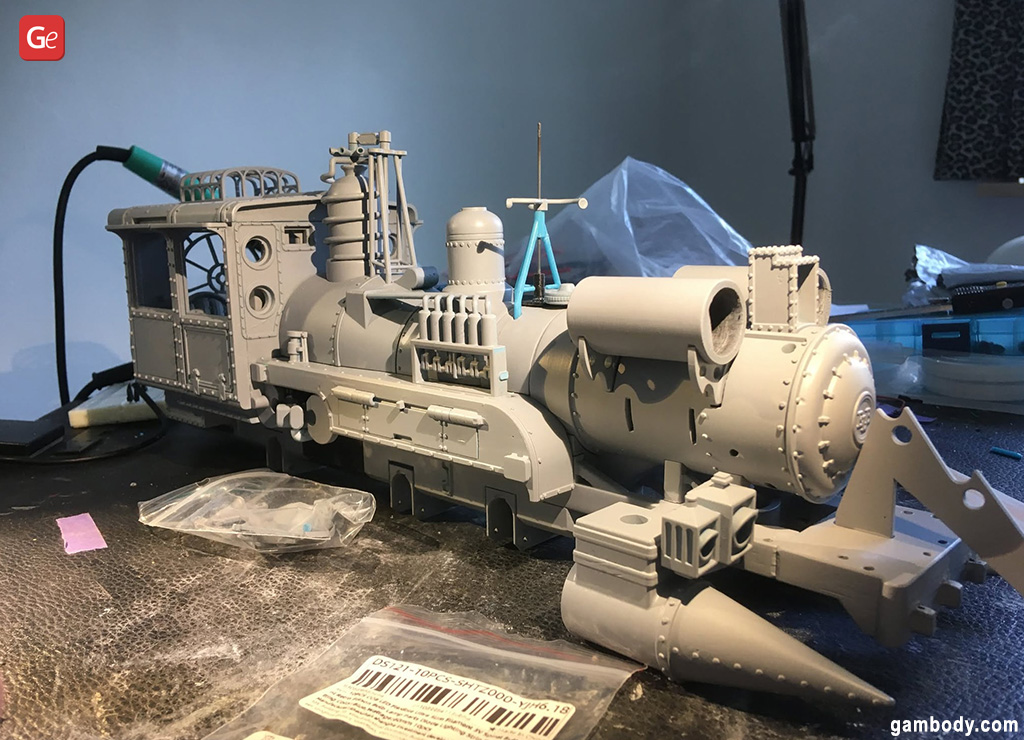

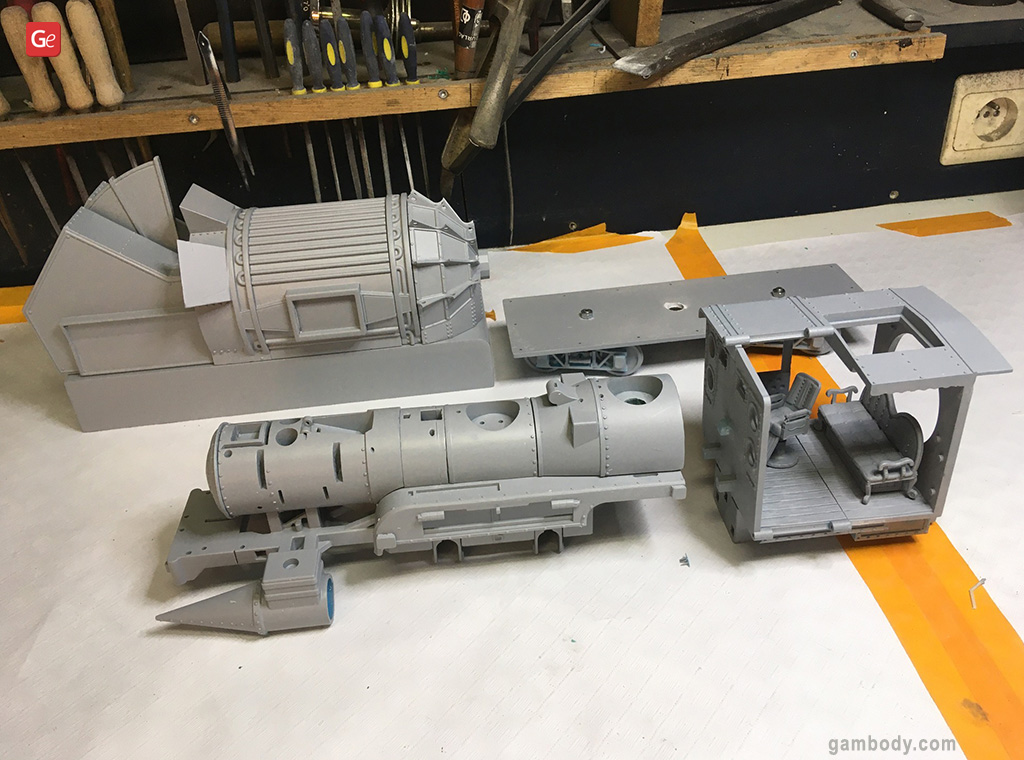

The design of the Back to the Future train parts was solid and logical to assemble. However, some tolerances, like the connectors for the trailer parts and cabin, were a bit tight. Since I used resin for 3D printing, sanding was straightforward.

I redesigned the railroad base for added realism and safety, incorporating metal supports to hold the train, as I didn’t trust the 3D printed rods included in the time train 3D model.

The Back to the Future locomotive’s internal channels for wiring from the lights could have been larger to accommodate more wires, as there’s enough space in the boiler barrels. I also added magnets to the locomotive’s wings (parts 1443-_16_side_hull_wing_R and 1443-_17_side_hull_wing_L) to secure them better and make them removable.

6. What animatronic features have you added to the BTTF train 3D model for printing? How hard was this process?

I integrated three electric motors, two smoke generators, and about 20 LEDs into the Back to the Future locomotive. I redesigned the barrel and chassis to house these components and their wiring.

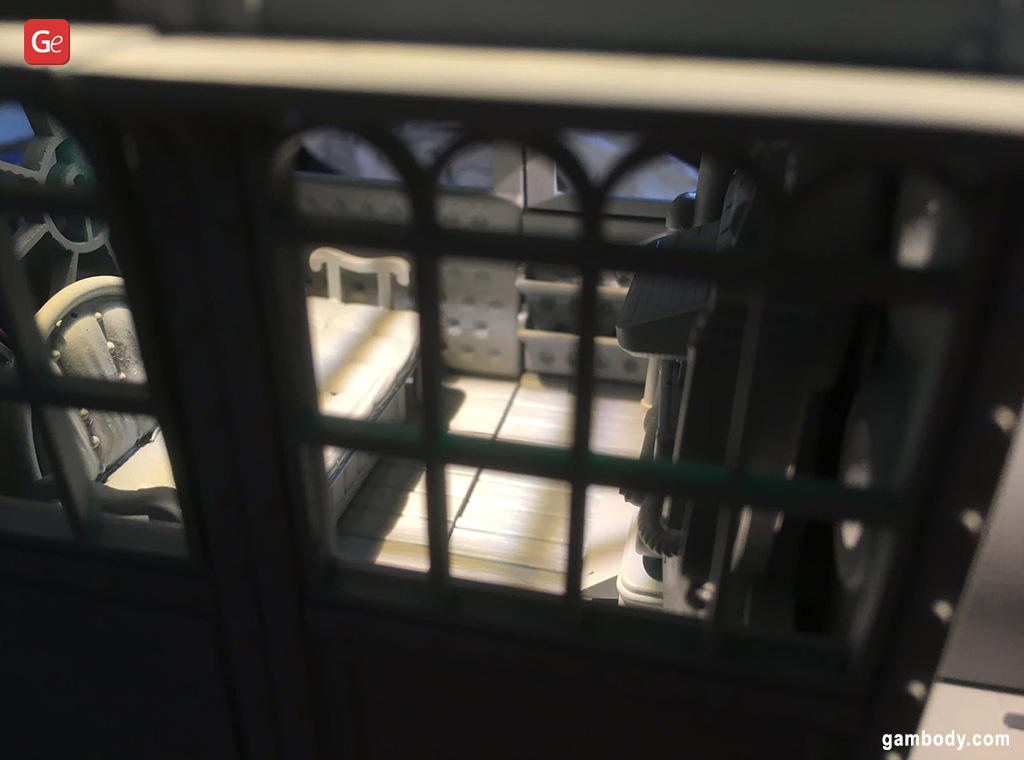

In the trailer, I added around 30 LEDs, a space for a microboard, and an LED strip.

Read also: How to Put Up LED Lights in a 3D Printed Model.

The trailer’s base was redesigned to be laser-cut from wood, which was faster than 3D printing and allowed space for electronics.

With my experience building animatronic miniatures, designing and integrating the motors was not particularly challenging.

7. Which 3D printers and how many machines did you use to print all the Jules Verne train model parts?

Prusa MK3, Creality LD06, an Xtools S1 laser, and maybe a few parts on my Anycubic Photon.

Read also: Best Cheap 3D Printer for a Beginner (Affordable Yet with Great Value).

8. You mentioned that your time train model has the 1/24 scale and is 80 cm long. How many spools of filament or liters of resin did this project require?

According to Gambody’s description, the FDM version of the Jules Verne train is listed as 1/32 scale, but when I measured the parts, it appeared closer to 1/24 scale. I used approximately 3 liters of resin and a bit of PLA.

9. How long did it take you to complete the Jules Verne train 3D print?

The printing process took about 60-70 hours (80% resin, 15% FDM, 5% wood and clay). The entire Back to the Future train model, including the base, took around two months to redesign and complete.

10. Can you describe your post-processing steps for preparing the parts of the time traveling train for painting?

- Adding primer and filler, sanding. Repeat this till the surfaces are smooth.

- Spraycan, airbrush, or handbrush for color.

- Adding decals.

- Adding a clear coat.

- Assembly.

Read also: Sanding and Painting 3D Prints (Easy Steps).

11. Which painting method did you use?

I used spray cans, airbrush, and handbrush techniques, inspired by the ’eavy metal’ style for color application.

12. Can you share more details about adding electronics to the 3D printed Back to the Future locomotive and train?

Designing a model with electronics is more complex than without. Without electronics, parts of the BTTF train can be glued together permanently after painting. With electronics, the model must be designed for disassembly to access components for testing or repairs. I also design internal wiring channels to hide wires, as exposed wiring detracts from the model’s appearance.

13. What parts of the train rotate and move?

- 1443-_31_parts_b_2_FDM (rotating spring on top of boiler barrel);

- 1443-_38_parts_c_2_FDM (rotating horns on top of boiler barrel);

- 1443-_21_parts_a_4_R_FDM (spools on the side of the Back to the Future locomotive).

14. What materials have you used for the time train cabin’s windows?

I used 0.8mm acrylic sheets in three colors: yellow, purple, and clear.

Read also: Tips for Making Clear 3D Prints in Transparent Filament and Resin.

15. What took you more time: printing, painting, and assembling, or adding and testing the electronics and LEDs?

Sanding and priming parts of the Jules Verne time train to get them smooth took the most time! I don’t like it when you see print layers in my finished models. Resin is easier to polish than the classic FDM-printed PLA.

16. You mentioned that the BTTF train has more lights than a Christmas tree. Have you counted how many LEDs you had to install in total?

Around 50 LEDs: filament LEDs and 3mm small LEDs. To be honest; I’m not sure how many lights are on an average Christmas tree :-).

17. What materials did you use to create the two onboard smoke generators?

I used oil-based smoke generators commonly found in train model brands like Märklin.

18. What did you like the most when working on this time travel train?

I enjoyed painting the interior by hand, drawing inspiration from the Warhammer “‘eavy metal” painting style. Adding color truly brings the model to life.

19. Where do you display the 3D printed Jules Verne Train?

In a display cabinet in a collection room.

20. Will your next 3D print be from Back to the Future?

Yes, I’m working on a 2015 Texaco station and a flying Ford Mustang. I’m also considering Doc’s 2015 binoculars and other stuff.

Gambody hopes that all enthusiasts who love BTTF films will add their 3D printed version of the Back to the Future train to their collection. Feel free to share the photos and videos of your Jules Verne time train and other projects on Gambody – 3D Printed Community Facebook page to inspire hobbyists from all over the world to take on new projects.