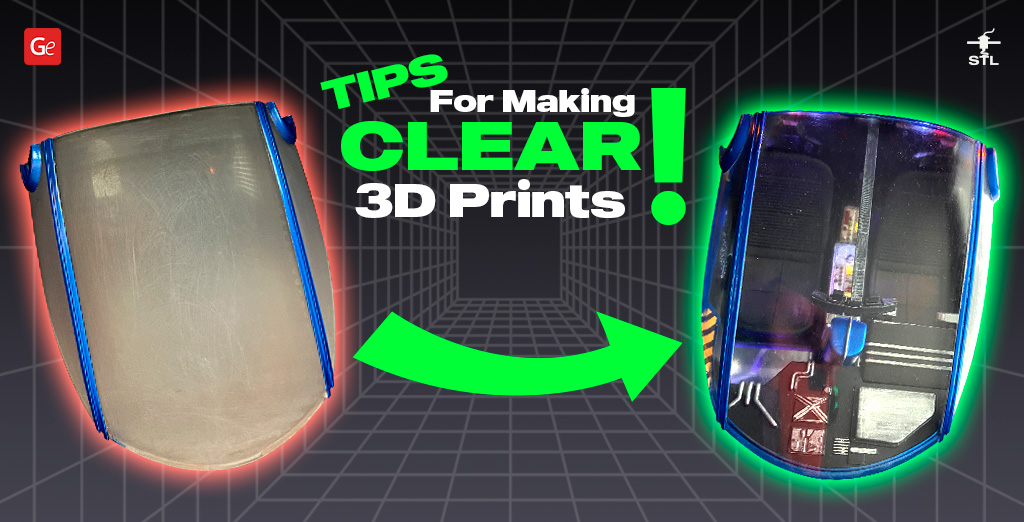

When working on the most impressive spaceships from Star Wars, Star Trek, Alien, and other galaxies, learning more about clear 3D printing is essential. Ships and cars must have windows, so follow Gambody’s instructions on creating transparent parts using clear 3D printer filament and resin.

Translucent and optically clear 3D printing can be handy for many great things. From transparent figures and water drops to complex dentist prototypes and realistic see-through pieces, whatever you wish to recreate will be simple after mastering some techniques and exploring the tips below.

Clear 3D Printing

Technology never stands still. Small and big companies take advantage of 3D printing and continue researching new engineering prospects that save time and money. Even if the company doesn’t make 3D printed cars, it can use clear 3D printing technology to test the efficiency of lubricant flow, as Chrysler did.

Some businesses started using clear 3D printer filament to make prescription lenses, both simple and integrated into AR/VR headsets. Luxexcel has already proven it to be a working solution.

Transparent 3D Printing

There are several methods of transparent 3D printing. Hobbyists can rely on clear plastics while working on any project with translucent parts. Below are tips for creating perfect models using clear resin 3D printing, FDM filaments, material jetting, and home materials.

Every method can lead to astonishing results. It’s only up to you which one to try or how to experiment to enjoy the best outcome. Each new clear 3D print will help you improve your skills and master the technique like a pro.

Clear Resin 3D Printing

Every clear resin print can look outstanding with the right technology and settings. Using exceptional materials and 100% infill density, you can make excellent transparent parts that look realistic after being cured in UV light.

Users who wish to achieve clear 3D prints with SLA should work hard while post-processing their parts. At first, the parts might look amazing, but the model can become yellowish and dull over time.

What are your choices?

- Method 1. Clean your clear resin prints before you cure the parts with UV light. Use isopropyl alcohol for this. Ensure you cure just the right amount of time and do not overdo it to avoid the yellowing effect in the future.

- Method 2. To simplify your experience, add some blue dye to your clear resin 3D print, neutralizing UV-curing’s yellowish effect. It might look perfect. But, in many situations, it can turn into a cloudy model.

- Method 3. You can find a 3D printing service that uses the Stratasys ProBleacher device and choose photobleaching as your post-processing. It might be expensive, but such clear resin 3D printing will be nearly perfect.

Transparent Resin Post-Processing Tips

After you cure your clear resin 3D printing parts, you should sand or polish them with 400-grit sandpaper, which you replace with other types through the 32,000-grit sandpaper.

Read also: Sanding and Painting 3D Prints (Easy Steps)

Spray on a transparent coat to protect the translucent 3D print, or finish it with lacquer. Also, you might want to dip a model into clear resin for a perfectly smooth finish effect.

Hobbyist Chris Kaniecki, for example, 3D printed Police Spinner transparent windshield in Dr.3D resin with ELEGOO Saturn, cured it with UV light, sanded the part starting with 800-grit and all the way to 32,000-grit sandpaper and then got rid of the cloudy effect by airbrushing the transparent windshield with Alclad Klear Kote. It took 5 or 6 clear coats to turn the cloudy piece into a glass-like crystal clear part.

Here is another stunning example of a clear resin 3D printing project made by Nathan Hartman, who sanded and polished the canopy for one afternoon:

When you wish to create a model with non-yellowing windows, try printing with Siraya Tech Craft Ultra Clear resin. Here is an example of how this material transforms into a stunning Gigahorse from Mad Max car:

Using the clear resin 3D printing method, you can also create a realistic tractor beam pulling a cow, as done by Alex Chiarelli, who transformed the Martian Flying Saucer model into a UFO:

Translucent 3D Printing with SLA Resin

If you are working on an expensive project, you can make the best clear resin 3D print using SLA for your machine. For projects in dentistry or another medical sphere, it is best to choose Nexa3D product, although its NXE xMEd 412 Clear resin costs nearly $2,000 per 11 lbs (5 kg).

You can use more affordable solutions for home display models, including Formlabs Clear Resin, Anycubic Clear, etc. They cost $26 to $149 per 2.2 lbs (1kg).

Other brands for stunning clear resin 3D printing results are Phrozen Aqua, SprintRay IDB 2 and Surgical Guide 3 Clear, Loctite 3D 3820 Ultra Clear, PhotoCentric DLP Flexible or Hard resin, and many others.

Read also: Free 3D Printing Software to Create 3D Prints

Clear 3D Printer Filament

When discussing FDM/FFF printers, you can turn a 3D printing clear plastic into a see-through piece if you use clear 3D printer filament and apply good post-processing work to remove visible ridges on the part edges and polish your plastic.

As you work with clear 3D printing filament, it is best to adjust your infill (make it lower), hot end temperature (make it higher), and layer height (it should be more significant) to achieve the optimal translucency effect.

X, Y, Z Tips

Keeping in mind your X-, Y-, and Z-axes is essential for the best clear 3D printing result. Here are some advice for hobbyists:

- If you need to 3D print a transparent window using clear 3D printer filament for a car or spaceship, ensure you achieve transparency perpendicular to your Z-axis;

- If you are making a 3D printed vase, it will look great with the clearness across its Y- and X-axes;

- If you wish to achieve the translucency in the Y- or X-axe, use a layer height that is at 75-90% or similar in size to your 3D printer nozzle diameter;

- If your whole project must be fully transparent, work in all your axes for the best result;

- Remember that bigger layers usually refract less light, resulting in an excellent clear 3D print;

- Ensure your 3D printing speed is lower by a third of the standard one;

- Increase the nozzle temperature to the maximum allowed by your clear 3D printer filament brand;

- Turn off the cooling or fan;

- Increase the flow rate to over 100% (it can be 105% or even slightly more).

Clear Filament Post-Processing Tips

After creating a transparent 3D print with an FDM printer, you should sand the parts really well and apply a clear coating. Different types of filament require specific treatments:

- If you are working with PolySmooth clear 3D printing material, you should spray the sanded parts with ethanol (give a few days for the project to completely dry), but too much of such a finish can make the parts less stable;

- Do not use a solvent on ABS filament to avoid getting a cloudy look;

- You can spray the polyurethane coating on your PLA and ABS 3D prints, which are known to create the best clear 3D prints among other filaments;

- Translucent PETG prints might not need any post-processing at all;

- If you use polycarbonate as your transparent 3D printing filament, print at high temperatures and finish the parts with acetone.

Here is an example of how clear 3D print made of PLA looks in a Thanos Infinity Gauntlet model:

Hobbyist Jérémie Bizart (Les Minutes Maker) used translucent PLA to recreate the Wasp figurine wings:

3D Print Clear Plastic via 3D Printing Service

While modern FDM and SLA 3D printers allow clear 3D printing with much post-processing work, some hobbyists think it is easier to use third-party 3D printing services once in a while. Such services often own industry-level printers that can flawlessly 3D print translucent and transparent parts in PLA, PETG, and other clear 3D printer filament or resin.

The best 3D printing services give you a choice of 3D printers, offering SLA, MSLA, and DLP machines that 3D print clear plastic and cure the models with UV light. Such a process is called vat polymerization.

Besides, a 3D printing service could offer you one of the Stratasys or Mimaki 3D printers that apply Polyjet technology or material jetting. They also use clear resin 3D printing technology (VeroClear, VeroUltraClear for Stratasys, and Pure Clear Ink for Mimaki) and cure parts with UV light. After being printed, such models are polished or covered with lacquer or go through photobleaching.

Custom Translucent Clear Parts

Your household items and some tricks can also do a miracle and help you create transparent parts for your 3D prints.

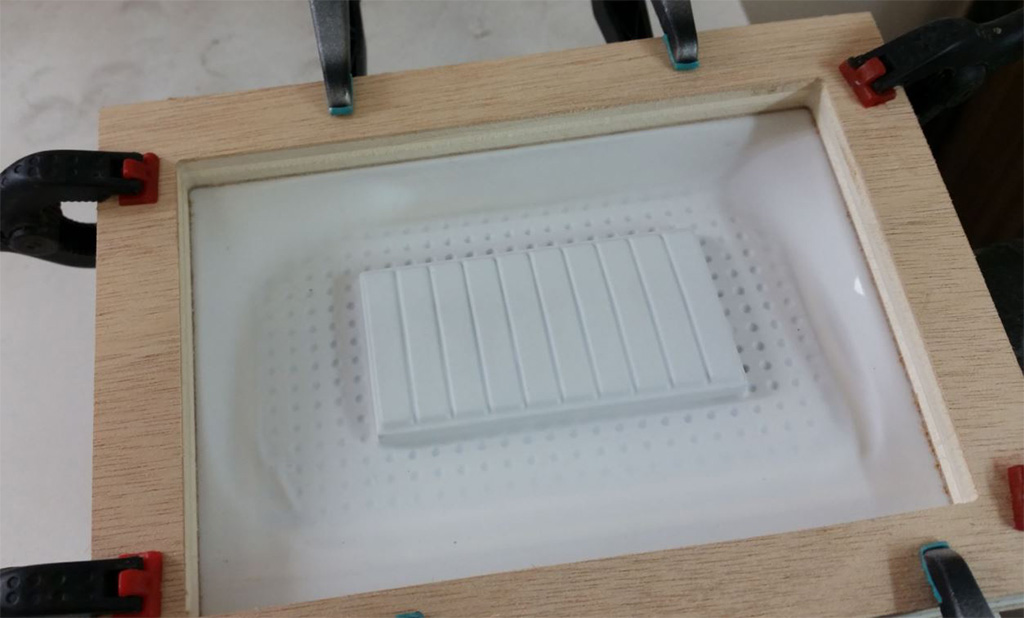

Enthusiast Guido Kehder suggests 3D printing the part you wish to be clear with PLA (or a different non-transparent filament), sand it very well, and thermoform it with a clear film. Or you can use it as your mold for forming a piece with epoxy resin.

Guide Kehder knows another method, too. Here is an example of a vacuum-drawn windshield fitted into the 3D printed Warthog M12B vehicle:

Enthusiast Liam Dillon also relied on the vacuum-forming method when working on his Mandalorian’s N-1 Starfighter:

Hobbyist Peter Rocco cuts the window shapes for his 3D prints from PET soft drink bottles.

Another enthusiast, Carlos Díaz, whose 3D printed DeLorean wows, used acetate sheets for car windows. However, he had to change the design to make it happen:

If you have a .030″ Lexan sheet, you can cut your clear windows from it as suggested by hobbyist Kym Ponik, whose 3D printed Type-11 Shuttlecraft amazes with details:

Enthusiast Roel Kroes is also very creative. While working on the Sentinel 3D print, the maker created many drops of hot glue for the monster’s eyes and introduced red LEDs to light them up.

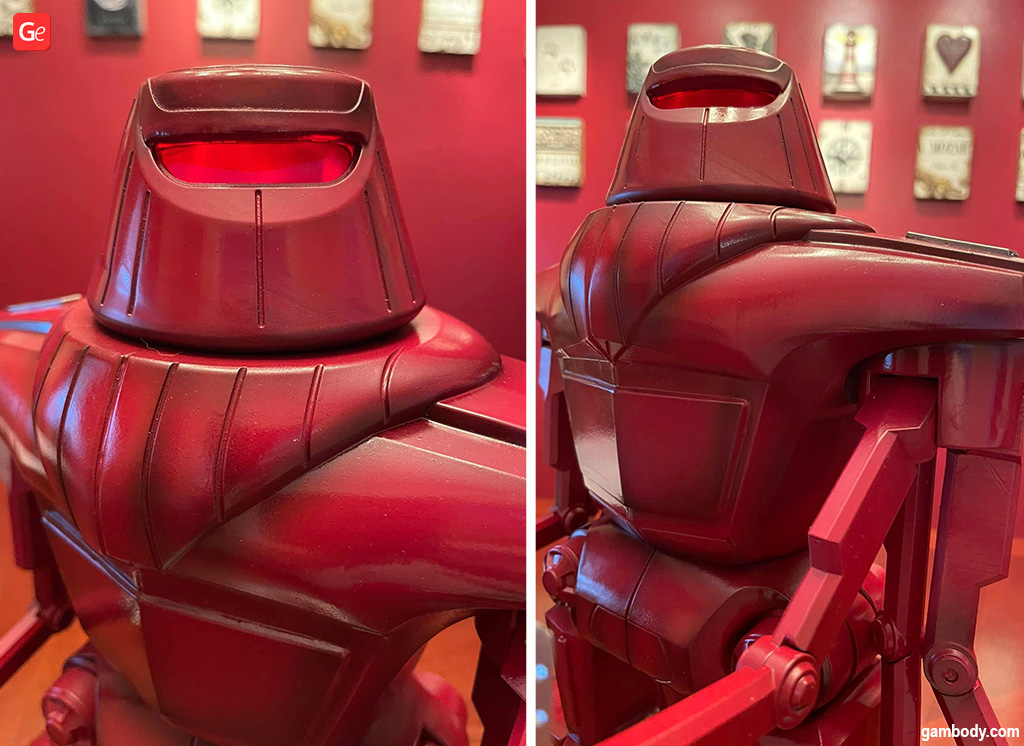

To create red “clear windows,” you can also rely on a method shared by Jerry Testa Jr., who used a piece of clear red acrylic for his Maximilian project:

Short vocabulary on 3D printing methods:

- SLA – stereolithography;

- MSLA – masked stereolithography;

- DLP – digital light processing;

- FDM – fused deposition modeling;

- FFF – fused filament fabrication;

- Polyjet – material jetting.

FAQ

Can you 3D print clear plastic?

Absolutely! Even average desktop 3D printers can print clear plastic. Thus, hobbyists can recreate transparent parts to make their clear 3D prints realistic.

However, turning PLA, ABS, and other plastic parts into transparent objects takes some setting tricks and much post-processing work. Only clear PETG prints often need no post-processing.