Files

3D model format

Stereolithography (.stl)

Total files

Slicer settings

not available

Mesh error check

not specified

Support

Lifetime support from Gambody team

Update requests

not specified

Model versions

FFF/FDM

Assembly method

not specified

Features

DLP/SLA

Assembly method

not specified

Features

Additional details

Part of diorama

No

Special pack included

No

You will get instant access to the STL files of Venator-class Star Destroyer 3D Printing Model | Assembly after completing your purchase. Simply add the model to your cart and check out using PayPal, credit or debit card, Apple Pay, Google Pay, Alipay, or other available payment methods.

Watch the assembly video for Venator-class Star Destroyer 3D Printing Model | Assembly, and explore more tutorials, behind-the-scenes content, 3D printing timelapses, and painting guides on the official Gambody YouTube channel.

This 3D Model of Venator-class Star Destroyer consists of files in StereoLithography (.Stl) format that is optimized for 3D printing.

Before printing the files, we strongly recommend reading the PRINTING DETAILS section.

WHAT WILL YOU GET AFTER PURCHASE?

- 2 versions of Venator-class Star Destroyer STL files for FFF/FDM and DLP/SLA - files for all versions are available for download after the purchase;

- STL files of high-poly Venator-class Star Destroyer’s 3D Model for 3D printing consist of 120 files;

Sizes for:

- FFF/FDM on the stand: 201 mm tall, 337 mm wide, 700 mm deep;

- FFF/FDM without the stand170 mm tall, 337 mm wide, 700 mm deep;

- DLP/SLA on the stand: 85 mm tall, 169 mm wide, 350 mm deep;

- DLP/SLA without the stand101mm tall, 169 mm wide, 350 mm deep;

- AssemblyManual for FFF/FDM 1.0 and DLP/SLA 1.0 versions in PDF and video formats;

- Detailed settings that we provide as a recommendation for Cura, Simplify3D, Slic3r and PrusaSlicer for the best print;

- Full technical support from the Gambody Support Team.

Detailed information about this 3D printing model is available in the DESCRIPTION section.

Before printing, take a look at Printing Details for recommended settings and tips to achieve better results.

ABOUT THIS 3D MODEL

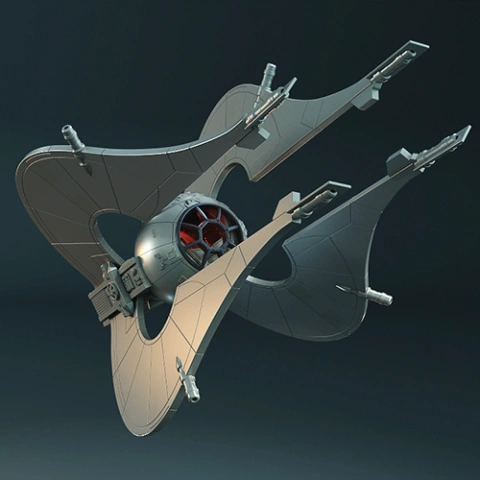

The Venator-class Star Destroyer is a type of capital ship used by the Galactic Republic during the Clone Wars. It was equipped with powerful weapons, including turbolasers, ion cannons, and tractor beams, making it a formidable opponent in battle. The ship was also equipped with hangar bays for starfighters, making it an effective carrier for supporting ground troops. The Venator was designed for a variety of missions, including combat, diplomacy, and exploration. The design was later adopted by the Galactic Empire, who used it as one of their primary warships in their naval forces.

ADAPTATION FOR 3D PRINTING

The Venator-class Star Destroyer for 3D printing is an active assembly model and its moderation and adaptation for different types of 3D printers took the Gambody team 55 hours in total.

For you to receive the cleanest 3D printing result possible, minimize the amount of filament needed for generated support, the spaceship was divided into convenient assembly parts.

All assembly parts in the FFF/FDM 1.0 version are provided in STL files in recommended positions that were worked out in order to ensure the smoothness of the details’ surfaces after printing and that the 3D printing beginners won't face difficulties when placing the parts on a build plate. When downloading any model's file you will also receive "Assembly Manual" for FFF/FDM 1.0 and DLP/SLA 1.0 versions in PDF format. We highly recommend that you get acquainted with the “Assembly video” and "Assembly Manual" before getting down to the Venator-class Star Destroyer.

The model is saved in STL files, a format supported by most 3D printers. All STL files for 3D printing have been checked in Netfabb and no errors were shown.

The model’s scale was calculated fromthe length of the Venator-class Star Destroyer The 3D printing model’s chosen scales are 1:1700 for the FFF/FDM version and 1:3400 for the DLP/SLA version.

VERSIONS’ SPECIFICATIONS

FFF/FDM 1.0 version features:

- Contains 78 parts;

- A printed model on the stand is 201 mm tall, 337 mm wide, 700 mm deep;

- A printed model without the stand is 170 mm tall, 337 mm wide, 700 mm deep;

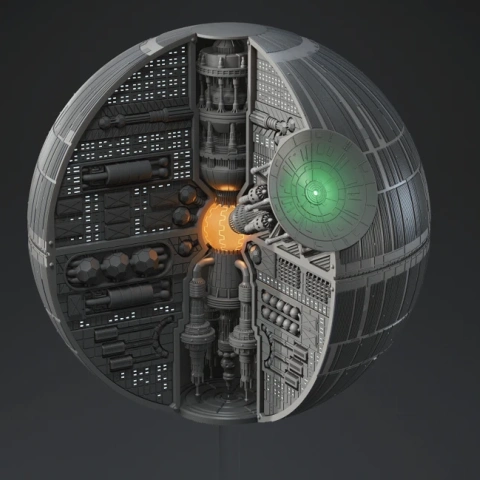

- Hangars doors can be installed in the closed or in the open position;

- The wings of the vessel are equipped with subsidiary reactors;

- The main reactor panel is hidden under the cover on the bridge tower;

- Rotating medium dual turbolasers along hull trench;

- Rotating heavy turbolaser turrets on either side of the bridge;

- Two window options - solid glass and frame with slots;

- Scaled LAAT/c, LAAT/i, and AT-TE can be stored in the hangar space;

- Articulated crane at the bottom;

- Tunnels for LED wiring;

- All parts are divided in such a way that you will print them with the smallest number of support structures.

DLP/SLA 1.0 version features:

- Contains 42 parts;

- A printed model without stand is 85 mm tall, 169 mm wide, 350 mm deep;

- A printed model on the stand is 101mm tall, 169 mm wide, 350 mm deep;

- Hangars doors can be installed in the closed or in the open position;

- The wings of the vessel are equipped with subsidiary reactors;

- The main reactor panel is hidden under the cover on the bridge tower;

- Two window options - solid glass and frame with slots;

- Scaled LAAT/c, LAAT/i, and AT-TE can be stored in the hangar space;

- Articulated crane at the bottom;

- Heavy turbolaser turrets can be set at 3 elevation angles;

- Tunnels for LED wiring;

- All parts are divided in such a way to fit the build plates and to ensure that support structures are generated where needed.

You can get the model of The Venator-class Star Destroyer for 3D Printing immediately after the purchase! Just click the green Buy button in the top-right corner of the model’s page. You can pay with PayPal or your credit card.

Watch the tutorial on how to assembleThe Venator-class Star Destroyer 3D Printing Model on Gambody YouTube channel.

Also, you may like the Star Destroyer and LAAT/i 3D Printing Models,andother Space Wars models for 3D Printing.

__________

FAQ:

Average customer rating (9 reviews)

5

Ratings breakdown

Click a star rating to filter reviews

Overall experience

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

To avoid printing issues and achieve the best quality, we highly recommend applying the following settings:

Generic

Below you can find printing recommendations for Cura, Bambu Lab, Simplify3D, Slic3r and PrusaSlicer software.

Disclaimer: The following printing settings are a recommendation, not an obligation. The parameters can vary depending on the peculiarities of your 3D printer, the material you use, and especially the particular assembly part you are working with. Each part that any model comprises often needs preliminary review, and you are free to tweak the settings the way you find suitable.

Note:

You can scale up the model (downscaling for FFF/FDM 3D printers is not recommended!);

All connectors should be printed at 100% Infill.

Bambu Lab printing recommendations:

These basic 3D printing settings recommendations for beginners were tested in Bambu Studio 1.9.5. Test models were printed on the Bambu Lab A1, Bambu Lab A1 Mini, Creality Ender 3 S1, Anycubic Kobra 2, and Anycubic Vyper using PLA and PETG filaments.

To avoid printing problems, we recommend the following settings:download

Cura printing recommendations:

These are averaged settings which were tested in the Cura 5.8.1 slicer. Test models were printed on Anycubic Vyper, Creality Ender 3 Pro with PLA filament.

To avoid printing problems, we recommend the following settings:download

Simplify3D printing recommendations:

These are averaged settings which were tested in the Simplify3D 5.0.0 slicer. Test models were printed on Anycubic Vyper, FLSUN v400, Ender3 S1 with PLA filament.

To avoid printing problems, we recommend the following settings:download

Slic3r printing recommendations:

These basic 3D printing settings recommendations for beginners were tested in Slic3r 1.3.0 software. Test models were printed on Ultimaker 2, Creality Ender 3, Creality Cr-10S pro v2, Anycubic I3 Mega, Anycubic I3 MegaS, Anycubic Vyper with PLA and PetG filaments.

To avoid printing problems, we recommend the following settings:download

PrusaSlicer printing recommendations:

These basic 3D printing settings recommendations for beginners were tested in PrusaSlicer 2.3.1. Test models were printed on Ultimaker 2, Creality Ender 3, Creality Cr-10S pro v2, Anycubic I3 Mega, Anycubic I3 MegaS, Anycubic Vyper with PLA and PETG filaments.

To avoid printing problems, we recommend the following settings:download