Files

3D model format

Stereolithography (.stl)

Total files

Slicer settings

Mesh error check

not specified

Support

Lifetime support from Gambody team

Update requests

not specified

Model versions

FFF/FDM

Assembly method

Connectors, Filament pieces

Features

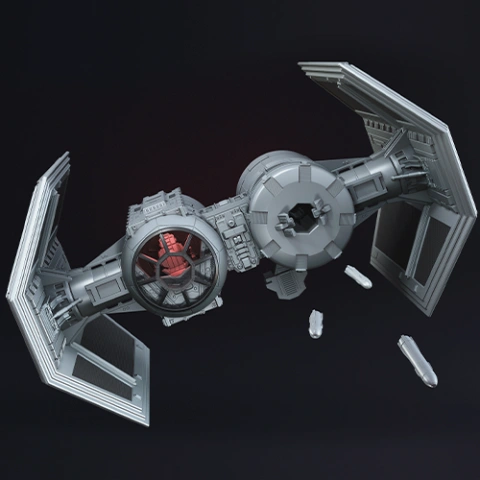

Improved FFF/FDM 3.0 version;

Modified to feature a pilot in the cockpit;

You can 3D print the pilot independently or as one piece with the seat;

The assembly of an articulated canopy requires an additional "pin" that can be made out of a short piece of regular 1.75mm filament;

DLP/SLA

Assembly method

Connectors, Paper Clip

Features

Improved DLP/SLA 1.0 version;

Modified to feature a pilot in the cockpit;

You can 3D print the pilot independently or as one piece with the seat;

Features canopy on the hinge and without it;

The canopy can be 3D printed as one piece or with insertable glass parts;

The pilot controls come separately for more a convenient painting process;

The assembly of an articulated canopy requires an additional "pin" that can be made out of a short piece of a regular paperclip;

FFF/FDM

Assembly method

Connectors, Filament pieces

Features

The assembly of an articulated canopy requires an additional "pin" that can be made out of a short piece of regular 1.75mm filament;

DLP/SLA

Assembly method

Connectors, Paper Clip

Features

The assembly of an articulated canopy requires an additional "pin" that can be made out of a short piece of a regular paperclip;

FFF/FDM

Assembly method

Connectors

Features

Outdated version of the T-65B X-Wing 3D printing model released in 2018;

The version's scale was calculated from the 12500 mm length of the craft;

FFF/FDM

Assembly method

Connectors

Features

Outdated version of the T-65B X-Wing 3D printing model released in 2017;

The version's scale was calculated from the 12500 mm length of the craft;

FFF/FDM

Assembly method

Connectors

Features

Outdated version of the T-65B X-Wing 3D printing model released in 2016;

The versions' scale was calculated from the 12500 mm length of the craft;

Additional details

Part of diorama

No

Special pack included

No

You can get the STL Fiels of T-65B X-Wing model immediately after the purchase! Just click the green Buy button in the top-right corner of the model’s page. You can pay with PayPal or your credit card.

Watch the tutorial on how to assemble the 3D Printed T-65B X-Wing model from the provided 3D Print Files at Gambody YouTube channel.

Also, you may like other Spacecrarft 3D Printing Designs.

_______

FAQ:

This 3D model comes with StereoLithography (.STL) files optimized for 3D printing. You'll get digital files, not a physical product

Before printing, take a look at Printing Details for recommended settings and tips to achieve better results.

T-65B X-Wing 3D Printer Files | Assembly includes 2 version(s) for the supported 3D printer type(s): FFF/FDM, DLP/SLA. Files are available for download after purchase.

See the Description and Specifications sections for more details about this model.

3D model history

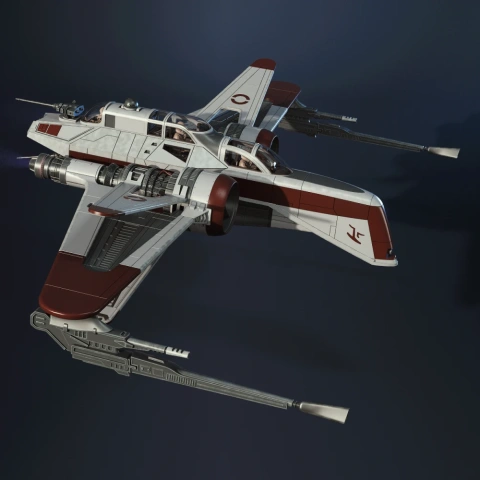

Several incredible victories in the struggle against the Galactic Empire earned the versatile X-wing the status of a symbol of the Rebellion. The fictional spacecraft boasts superior firepower, it is capable of long-range jumps with its hyperdrive, and it proved to be pretty manoeuvrable when acting in a cramped space! It was the T-65B X-wing starfighter that Luke Skywalker piloted to destroy the Death Star in 1977 Star Wars: A New Hope.

It is obvious that no 3D printing Star Wars fleet is complete without a T-65B X-wing. Fortunately, by the efforts of our talented contributing 3D artist, the iconic Incom Corporation spacecraft can be easily brought to life! The 3D printing T-65B X-wing starfighter carries articulated strike foils or "S-foils" (wings) for you to display the craft in an attack position. Also, the socket behind the cockpit houses a trusty astromech droid - R2-D2 or R4 - who are known to be super skilled at saving the day!

3D printing model features

Model-specific features:

- There are two alternative types of opening canopy - a solid canopy and a frame without glass parts;

- The highly detailed cockpit module is equipped with a pilot seat;

- There are two variants of astromech droid to fit into the socket behind the cockpit - R2-D2 or R4;

- There is a mechanism inside the ship that allows simultaneous movement of the wings up and down;

- Set the mechanism of “S-foils” (wings) in motion by rotating the head of the astromech droid;

- Display X-wing with extended landing gear or conceal its slots with caps, or mount the ship on a platform or conceal the slot with a cap;

- The model is made hollow for you to introduce LED wiring and light up the cockpit; the battery can be hidden inside the nose of the starfighter;

Printing & assembly details:

- Provided as error-free STL files compatible with most 3D printers;

- Optimized part division minimizes support material and ensures smooth surface detail;

- The assembly parts in the FFF/FDM version come in the recommended print orientations for easy bed placement;

- Assembly manual in PDF and video formats are included for 3.0 FFF/FDM and 3.0 DLP/SLA versions;

- The model is available in recommended scales of 1:34 for the FFF/FDM version and 1:68 for the DLP/SLA version, based on the 13400 mm length of the T-65B X-Wing.

What will you get after purchase?

- 4 updated + 3 initial versions of T-65B X-Wing Starfighter STL files for FFF/FDM and DLP/SLA — files for all versions are available for download after the purchase;

- STL files of high-poly T-65B X-Wing Starfighter model for 3D printing consist of 113 files;

- Sizes for:

- FFF/FDM: 329 mm wide, 189 mm high, 394 mm deep;

- DLP/SLA: 164 mm wide, 94 mm high, 197 mm deep;

- Assembly Manual for FFF/FDM 3.0 and DLP/SLA 1.0 versions in PDF format;

- Detailed settings that we provide as a recommendation for Bambu Studio, Cura, Orca Slicer, PrusaSlicer, Simplify3D, and Slic3r for the best print;

- Full technical support from the Gambody Support Team.

Average customer rating (51 reviews)

4.5

Ratings breakdown

Click a star rating to filter reviews

Overall experience

Level of detail in the model

4.5

Model cut quality and assembly guide

4.6

Clarity and accuracy of the model page

4.6

Level of detail in the model

4.6

Model cut quality and assembly guide

4.8

Clarity and accuracy of the model page

5

Thank you for your detailed feedback and for sharing your build photos! We’re really happy to hear the parts fit together perfectly and that you love the final result!

Regarding the S-foils mechanism (controlled via the astromech droid head): this feature was intentionally designed as a hidden internal mechanism to create a “wow” effect while keeping the exterior clean. It also helps prevent the wings from wobbling and provides a more stable, fixed position when opened or closed.

That said, we completely understand that some hobbyists may prefer a simpler manual approach — and your solution (leaving out one gear and moving the wings by hand) is a great practical alternative.

If you’re open to sharing one more detail, it would help us a lot: was the issue mainly related to print tolerances (too tight/too loose), smoothness of rotation, or just personal preference for a simpler mechanism?

Thanks again for your support and for taking the time to leave such a thoughtful review!

Level of detail in the model

2.1

Model cut quality and assembly guide

3.3

Clarity and accuracy of the model page

4.3

The model can be best described as "X-Wing like", because the details are nothing like the studio model. It is very toy-like. Now that I have printed and built it, I would not actually buy it again if I knew what the end result was.

Please note that all models on our marketplace are original creations made by Gambody’s contributing 3D artists. They are not exact copies of existing items or products. Each project is also carefully adapted for optimal 3D printing by our Moderation Team, which sometimes requires design decisions that differ from the on-screen version.

The T-65B X-Wing 3D model is continuously updated and refined with several versions currently available. It would be extremely helpful if you could specify which version you printed, along with the order details. We would also appreciate it if you could email us more information about the specific inaccuracies you noticed at support@gambody.com so we can forward them to the Moderation Team for detailed review.

Please also rest assured that once you purchase a model, you always have access to all future updates and newer versions. This means you are welcome to re-download and print the latest version of the model at any time.

Regarding the tolerances: slight inconsistencies in fit can occur when printing with resin due to factors like shrinkage, exposure settings, or individual printer calibration. Even with high-resolution machines, small variations in curing can cause tighter connections, which is why some light sanding or minor adjustment may be needed during assembly. It may also help to apply a small amount of oil when fitting certain parts together.

We appreciate your input in helping us improve the T-65B X-Wing 3D model to make it as accurate as possible. Please let us know if there's anything else we can assist you with!

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

4

Model cut quality and assembly guide

4

Clarity and accuracy of the model page

4

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

4

Model cut quality and assembly guide

4

Clarity and accuracy of the model page

4

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

4

Model cut quality and assembly guide

4

Clarity and accuracy of the model page

4

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

4

Model cut quality and assembly guide

4

Clarity and accuracy of the model page

4

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

4

Model cut quality and assembly guide

4

Clarity and accuracy of the model page

4

Level of detail in the model

4

Model cut quality and assembly guide

4

Clarity and accuracy of the model page

4

Level of detail in the model

4

Model cut quality and assembly guide

4

Clarity and accuracy of the model page

4

Below you'll find detailed slicing settings for Bambu Studio 2.0+, Orca Slicer 2.0+, UltiMaker Cura 5.0+, PrusaSlicer 2.0+, Slic3r 1.3+, Simplify3D 5.0+ to help you get the best results when printing this model. These settings are optimized specifically for this 3D model, but please note they may need slight adjustments depending on your printer or filament. When in doubt, refer to your printer's user manual.

To avoid printing issues and achieve the best quality, we highly recommend applying the following settings:

For better quality use 0.12 mm layer height, for fast printing use 0.2 mm layer height. For pins and the Ge connectors, use 0.2 layer height.

120-150% of your Layer Height

But you can paint the seam if you want.

You have to calibrate this parameter

You have to calibrate this parameter

You have to calibrate this parameter

For pins and power elements of the structure, such as the vehicle frame, use 3 loop

Disabled for vehicles and enabled for characters

For 0,2 Layer Height

The parameters in this tab vary greatly, it all depends on the quality of your printer. For example, if you have a classic Ender3, stick to the minimum parameters, but if you have a newer printer, for example Anycubic cobra 3 v2, you can select the maximum recommended values

Settings for advanced users, change these parameters only if you have sufficient 3D printing expertise

Enable this parameter if your model requires supports

We also recommend placing and removing supports manually in some places using special button

1-2 loops for more thick support

Top Z distance = 1-1.3 layer Height. If the supports are hard to remove, try increasing this setting by 0.1-0,4 mm

Bottom Z distance = 1-1.3 layer Height. If the supports are hard to remove, try increasing this setting by 0.1-0,4 mm

You have to calibrate this parameter which one is better for your filament

Increase this parameter if the supports are hard to remove from walls

For PLA and PETG filament types

5-8 mm is optional for small prints that have bad adhesion to the build plate

You have to calibrate this parameter

Read the description on your filament roll

Read the description on your filament roll and increase this parameter for fast printers

Read the description on your filament roll and increase this parameter for fast printers

For better quality use 0.12 mm layer height, for fast printing use 0.2 mm layer height. For pins and the Ge connectors, use 0.2 layer height.

120-150% of your Layer Height

But you can paint the seam if you want.

0.01-0.05 You have to calibrate this parameter

0.01-0.05 You have to calibrate this parameter

0.1-0.2 You have to calibrate this parameter

For pins and power elements of the structure, such as the vehicle frame, use 3 loop

Disabled for vehicles and ships, enabled for characters

For 0,2 Layer Height

For 0,2 Layer Height

The parameters in this tab vary greatly, it all depends on the quality of your printer. For example, if you have a classic Ender3, stick to the minimum parameters, but if you have a newer printer, for example, Anycubic Kobra 3 Or Bambulab A1, you can select the maximum recommended values.

Settings for advanced users, change these parameters only if you have sufficient 3D printing expertise

Enable this parameter if your model requires supports

We also recommend placing and removing supports manually in some places using special button

Top Z distance = 1-1.3 layer Height. If the supports are hard to remove, try increasing this setting by 0.1-0,4 mm

Bottom Z distance = 1-1.3 layer Height. If the supports are hard to remove, try increasing this setting by 0.1-0,4 mm

Increase this parameter if the supports are hard to remove from walls

For PLA and PETG filament types

5-8 mm is optional for small prints that have bad adhesion to the build plate

Read the description on your filament roll

Read the description on your filament roll and increase this parameter for fast printers

You have to calibrate this parameter

Read the description on your filament roll and increase this parameter for fast printers

Read the description on your filament roll

This field is filled in according to your printer specifications when you add it to the slicer.

You can add custom G-code here for the start and end of the print. However, be careful - this is for advanced users only!

You have to calibrate your printer using Ge retraction test models

Retraction Length: For direct-drive setups use 0.5 mm to 2.5 mm; for Bowden extruders use 5 to 7 mm

This is how fast the filament is pulled back—40-60 mm/s for direct drive and 30-50 mm/s for Bowden setups.

You have to calibrate this parameter: Reduce it until the printer starts to hit the parts with the nozzle during printing, then increase it by 0.2.

For better quality use 0.12 mm layer height, for fast printing use 0.2 mm layer height. For pins and the Ge connectors, use 0.2 layer height.

120-150% of your Layer Height

To increase the strength of the print parts, use wall line count: 3

For pins and connectors use 50% Infill

These parameters are for standard PLA plastic. If you are using a different type of plastic, check the printing temperature recommended by the manufacturer. Also, read the description on your filament spool. For fast printers, add +30 °C to the current parameters.

The parameters in this tab vary greatly, it all depends on the quality of your printer. For example, if you have a classic Ender3, stick to the minimum parameters, but if you have a newer printer, for example Anycubic cobra 3 v3, you can select the maximum recommended values

Settings for advanced users, change these parameters only if you have sufficient 3D printing expertise.

You need to calibrate this parameter using Gambody test models. These values are average values for a Direct Drive extruder; for a Bowden extruder, the values should be increased.

You need to calibrate this parameter using Gambody test models. These values are average values for a Direct Drive extruder; for a Bowden extruder, the values should be increased.

Use this value other than 0 if your nozzle catches on the internal infill during travel moves. Try to keep this value as low as possible in height.

Use normal supports to support large, straight surfaces (most mechanical or technical parts).

You have to calibrate this parameter according to the capabilities of your printer and your filament, using a Gambody test models.

Use 1 instead of 0 if your supports are thin and tall. They will be harder to remove, but much stronger.

Top Z distance = 1-1.3 layer Height. If the supports are hard to remove, try increasing this setting by 0.1-0,4 mm

Increase this parameter if the supports are hard to remove from walls

Use tree supports to support complex objects, such as characters.

You have to calibrate this parameter according to the capabilities of your printer and your filament, using a Gambody test models.

Top Z distance = 1-1.3 layer Height. If the supports are hard to remove, try increasing this setting by 0.1-0,4 mm

Increase this parameter if the supports are hard to remove from walls

Use a skirt for all parts when printing on outdated printers.

Use a brim when printing thin but tall parts, as well as parts with a small bed adhesion area.

For better quality use 0.12 mm layer height, for fast printing use 0.2 mm layer height. For pins and the Ge connectors, use 0.2 layer height.

120-150% of your Layer Height

for 0.2 Layer Height

But you can paint the seam if you want.

(for PLA and PETG)

(5-8 mm is optional for small prints that have bad adhesion to the build plate)

Enable this parameter if your model requires supports

(45-50 degree)You have to calibrate this parameter according to the capabilities of your printer

and your filament, using a Gambody test models.

Top contact Z distance = 1-1.3 layer Height. If the supports are hard to remove, try

increasing this setting by 0.1-0,4 mm

Top contact Z distance = 1-1.3 layer Height. If the supports are hard to remove, try

increasing this setting by 0.1-0,4 mm

Increase this parameter if the supports are hard to remove from walls

The parameters in this tab vary greatly, it all depends on the quality of your printer. For example, if you have a classic Ender3, stick to the minimum parameters, but if you have a newer printer, for example Anycubic cobra 3 v3, you can select the maximum recommended values

Settings for advanced users, change these parameters only if you have sufficient 3D printing expertise. Use the minimum value for outdated printers without acceleration calibration, and the maximum value for modern printers if you need it.

These settings only work for 3D printers with multiple extruders

You can try setting all parameters in this section, except the First layer, to values between 0.75% of your nozzle diameter and 1.25% of your nozzle diameter. Adjusting them will help you work out the optimal parameters for the best quality for your print. As for the First layer, you can set it to 150% of the diameter of your nozzle for better adhesion to the build plate (for a nozzle with a diameter of 0.4 mm, the First layer extrusion width can be from 0.3 mm to 0.5 mm)

For better printing quality you have to calibrate this parameter using Gambody test model.

Check your filament manufacturer's temperature recommendations on the spool.

Cooling parameters depends on the material you use for printing.

*for PLA

For better quality use 0.12 mm layer height, for fast printing use 0.2 mm layer height. For pins and the Ge connectors, use 0.2 layer height.

120-150% of your Layer Height

For 0.12 Layer Height

For 0.12 Layer Height

For pins and connectors use 50% Infill

Use skirt for outdated 3d printers

(5-8 mm is optional for small prints that have bad adhesion to the build plate)

Enable this parameter if your model requires supports

(45-60 degree)You have to calibrate this parameter according to the capabilities of your printer and your filament, using a Gambody test models

Contact Z distance = 1-1.3 layer Height. If the supports are hard to remove, try increasing this setting by 0.1-0,4 mm

The parameters in this tab vary greatly, it all depends on the quality of your printer. For example, if you have a classic Ender3, stick to the minimum parameters, but if you have a newer printer, for example Anycubic cobra 3 v3, you can select the maximum recommended values

Settings for advanced users, change these parameters only if you have sufficient 3D printing expertise. Use the minimum value for outdated printers without acceleration calibration, and the maximum value for modern printers if you need it.

You have to calibrate this parameter from 0.9 to 1.1 according to the capabilities of your printer and your filament, using a Gambody test models.

Check your filament manufacturer's temperature recommendations on the spool.

Cooling parameters depends on the material you use for printing.

Calibrate this value if you need to reduce or improve the adhesion between the plastic and the heat bed

Your current nozzle diameter

You need to calibrate this parameter using Gambody test models. These values are average values for a Direct Drive extruder; for a Bowden extruder, the values should be increased.

Your current nozzle diameter

You have to calibrate this parameter using Gambody test models.

You need to calibrate this parameter using Gambody test models. These values are average values for a Direct Drive extruder; for a Bowden extruder, the values should be increased.

For better quality use 0.12 mm layer height, for fast printing use 0.2 mm layer height. For pins and the Ge connectors, use 0.2 layer height.

For 0,2 Layer Height

For 0,2 Layer Height

To increase the strength of the print parts, use Outline Perimeters: 3

You can enable this parameter to print rounded or spherical models, as well as character models.

Use this option only if your parts are too tight. but better calibrate your printer extrusion

Use this option only if your parts are too tight. but better calibrate your printer extrusion

Use 2 and more if you want to create skirt instead brim

1-2 for skirt and 10-20 for brim

Use for wipe nozzle if you need

Use For ABS filament

For pins and connectors use 50% Infill

Top Z distance = 1-1.3 layer Height. If the supports are hard to remove, try increasing this setting by 0.1-0,4 mm

Calibrate your filament and detect optimal temperature for it

Average temperature for PLA filament

The parameters in this tab vary greatly, it all depends on the quality of your printer. For example, if you have a classic Ender3, stick to the minimum parameters, but if you have a newer printer, for example Anycubic cobra 3 v3, you can select the maximum recommended values

Settings for advanced users, change these parameters only if you have sufficient 3D printing expertise.

DLP/SLA

Improved DLP/SLA 1.0 version;

Modified to feature a pilot in the cockpit;

You can 3D print the pilot independently or as one piece with the seat;

Features canopy on the hinge and without it;

The canopy can be 3D printed as one piece or with insertable glass parts;

The pilot controls come separately for more a convenient painting process;

The assembly of an articulated canopy requires an additional "pin" that can be made out of a short piece of a regular paperclip;

FFF/FDM

Improved FFF/FDM 3.0 version;

Modified to feature a pilot in the cockpit;

You can 3D print the pilot independently or as one piece with the seat;

The assembly of an articulated canopy requires an additional "pin" that can be made out of a short piece of regular 1.75mm filament;

DLP/SLA

The assembly of an articulated canopy requires an additional "pin" that can be made out of a short piece of a regular paperclip;

FFF/FDM

The assembly of an articulated canopy requires an additional "pin" that can be made out of a short piece of regular 1.75mm filament;

FFF/FDM

Outdated version of the T-65B X-Wing 3D printing model released in 2018;

The version's scale was calculated from the 12500 mm length of the craft;