Files

3D model format

Stereolithography (.stl)

Total files

Slicer settings

not available

Mesh error check

not specified

Support

Lifetime support from Gambody team

Update requests

not specified

Model versions

FFF/FDM

Assembly method

not specified

Features

DLP/SLA

Assembly method

not specified

Features

SLS

Assembly method

not specified

Features

DLP/SLA

Assembly method

not specified

Features

Additional details

Part of diorama

No

Special pack included

No

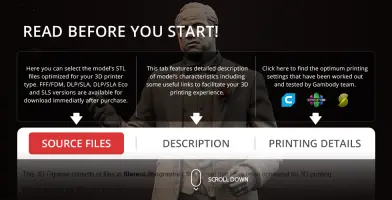

You will get instant access to the STL files of The Godfather 3D Printer Files | Assembly after completing your purchase. Simply add the model to your cart and check out using PayPal, credit or debit card, Apple Pay, Google Pay, Alipay, or other available payment methods.

Watch the assembly video for The Godfather 3D Printer Files | Assembly, and explore more tutorials, behind-the-scenes content, 3D printing timelapses, and painting guides on the official Gambody YouTube channel.

This 3D Figurine consists of files in StereoLithography (.Stl) format that is optimized for 3D printing.

Before printing the files, we strongly recommend reading the PRINTING DETAILS section.

The Godfather 3D Printing Figurine comes in 4 versions for each 3D printer type (FFF/FDM, DLP/SLA and SLS). Files for each version are available for download after the purchase.

Detailed information about this 3D printing figurine is available in the DESCRIPTION section.

Before printing, take a look at Printing Details for recommended settings and tips to achieve better results.

ABOUT THIS 3D MODEL

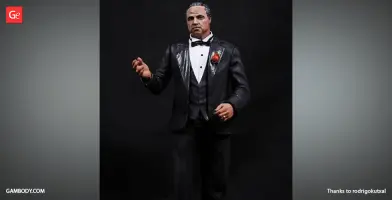

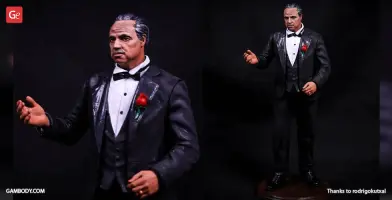

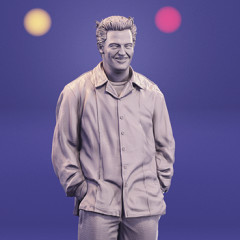

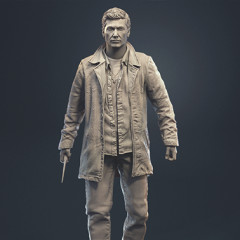

The fictional character of Vito Corleone that appeared for the first time in Mario Puzo's 1969 novel “The Godfather” seems to be the embodiment of the canonic mafia face. Later on, he was masterfully portrayed by Marlon Brando in the 1972 movie of the same name that achieved iconic status, setting the trends not only for the mafia-themed films but also for general cinematography for lots of years ahead. Delving into the criminal atmosphere of post-war times in “The Godfather”, the author of this 3D printing figurine spent circa 132 hours in order for any franchise fan to have an opportunity to 3D print the Don of the Corleone family. The first glimpse at the 3D printing Vito Corleone reveals the hidden overwhelming power of the character and smooth strength that allowed him to speak with no word pronounced - a gesture was enough. The author of the model depicted the patriarch sporting a formal tuxedo with slightly loose trousers that have a sharp center crease and a formal waistcoat. The classy Don for 3D printing is also portrayed wearing a non-adjustable bow tie and a wedding band on his left ring finger that represents his devotion to his wife Carmela. Last but not least, the author of the 3D printing figurine made sure to add a rosebud in the left lapel of Vito Corleone’s jacket that Don was wearing during his daughter’s wedding celebration. Seemingly menacing and ruthless, Vito is actually the man of a great heart, who obeys omertà, respects traditional Sicilian family values and even can adopt his son’s friend. The clan chieftain who knows how to do business, a family leader whose powers inspire awe not only within Long Island but make his rivals shiver hundreds of miles away. Yet the 3D printing Godfather figurine is going to make you an offer you can’t refuse - just print it and become closer to the mafia.

ADAPTATION FOR 3D PRINTING

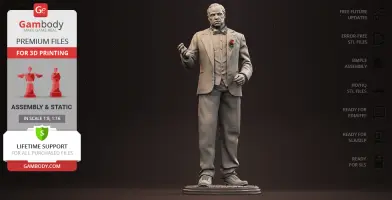

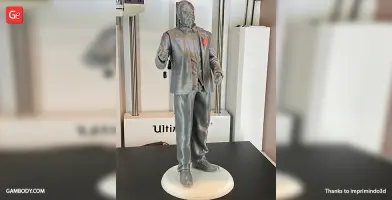

The Godfather figurine for 3D printing is a static assembly model and its moderation and adaptation for different types of 3D printers took Gambody team 35 hours in total. Figurine’s anatomy was thoroughly reviewed during the moderation process for the mafia Don to be depicted harmoniously in his sharp tuxedo and with his iconic restrainedbody language. The model’s cutting was chosen by our team to minimise the amount of filament needed for generated support and some of the parts were hollowed out for you to save resin in the figurine’s Eco version. In order to conceal the places where the assembly parts of the model must be connected, the figurine was cut along the contour of Vito Corleone’s suit seams. For you to achieve the cleanest 3D printed result, the Godfather’s head, hands and shoes were carefully separated, and even the rosebud was extracted from the left lapel of his jacket. All the assembly parts come in STL files in recommended positions that were worked out in order to ensure the smoothness of the details’ surfaces after printing and so that the 3D printing beginners won't face difficulties when placing the parts on a build plate. When downloading any figurine's file you will also receive "Assembly Manual" for FFF/FDM 1.0 and DLP/SLA 1.0 versions in PDF format.

The figurine is saved in STL files, a format supported by most 3D printers. All STL files for 3D printing have been checked in Netfabb and no errors were shown.

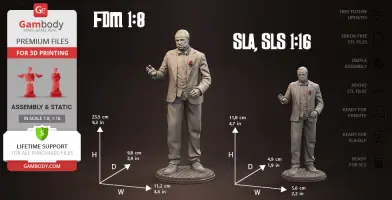

The model's scale was calculated from the actual height of Vito Corleone which is 1830 mm. The 3D printing figurine's chosen scale is 1/8 for the FFF/FDM version and 1/16 for the DLP/SLA/SLS versions.

VERSIONS' SPECIFICATIONS

FFF/FDM 1.0 version features:- Contains 14 parts;- A printed model is 235 mm tall, 112 mm wide, 98 mm deep;- Assembly kit includes lock 14_ge_lock_10H(x1) to attach the figurine's body to legs securely without glue that needs to be printed once;- All parts are divided in such a way that you will print them with the smallest number of support structures.

DLP/SLA 1.0 version features:- Contains 5 parts;- A printed model is 118 mm tall, 56 mm wide, 49 mm deep;- All parts are divided in such a way to fit the build plates and to ensure that support structures are generated where needed.

DLP/SLA Eco 1.0 version features:- Contains 5 parts;- A printed model is 118 mm tall, 56 mm wide, 49 mm deep;- Contains some hollowed out parts to save resin.

SLS 1.0 version features:- Made as a solid one-piece figurine;- A printed model is 118 mm tall, 56 mm wide, 49 mm deep;- Contains 3 parts - a one-piece model and the figurine with the platform separated.

WHAT WILL YOU GET AFTER PURCHASE?

- STL files of The Godfather 3D Figurine for 3D printing which consist of 27 parts;- 4 versions of files for this model for FFF/FDM, DLP/SLA, DLP/SLA Eco and SLS;- High-poly detailed figurine of The Godfather;- Assembly Manual for FFF/FDM 1.0 and DLP/SLA 1.0 versions in PDF format;- Detailed settings that we provide as a recommendation for Cura , Simplify3D and Slic3r for the best print;- Full technical support from the Gambody Support Team.

You can get the figurine of The Godfather for 3D Printing immediately after the purchase! Just click the green Buy button in the top-right corner of the model’s page. You can pay with PayPal or your credit card.

Watch the tutorial on how to assemble The Godfather 3D Printing Model at Gambody YouTube channel.

Also, you may like other Heroes 3D Printing Model.

_______FAQ: Where can I print a model if I have no printer?How to get started with 3D printing?How to set up my 3D printer?How to choose right 3D model print bed positioning? How to paint printed figurine?

Average customer rating (8 reviews)

4.9

Ratings breakdown

Click a star rating to filter reviews

Overall experience

Level of detail in the model

4.9

Model cut quality and assembly guide

4.9

Clarity and accuracy of the model page

4.9

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

4

Model cut quality and assembly guide

4

Clarity and accuracy of the model page

4

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

To avoid printing issues and achieve the best quality, we highly recommend applying the following settings:

Generic

Below you can find printing recommendations for Cura, Simplify3D and Slic3r software.

Cura printing recommendations:

These are basic settings that were tested in Cura 4.8.0 slicer.

The test models were printed on Ultimaker 2, Creality Ender 3, Creality CR-10S Pro V2, Anycubic I3 Mega, Anycubic I3 MegaS 3D printers with PLA and PETG filaments.

Disclaimer: The following printing settings are a recommendation, not an obligation. The parameters can vary depending on the peculiarities of your 3D printer, the material you use and especially the particular assembly part at hand. Each part that any model comprises often needs preliminary review and you are free to tweak the settings the way you find suitable.

Note:

- You can scale up the model (downscaling is not recommended!);

- All connectors should be printed at 100% Infill;

- For all parts of locks (“ge_lock” in “Source files”) you need to change "Brim" type to "Skirt" in Build Plate Adhesionsection.

Quality

Layer Height: 0.12 mm (you can also set Layer Height at 0.16 or 0.2mm for 0.4mm nozzles)

Initial Layer Height: 0.2 mm (carefully level the print bed and keep your Initial Layer Height the same as the main Layer Height)

Line Width: 0.4 mm

Wall Line Width: 0.4 mm

Outer Wall Line Width: 0.4 mm

Inner Wall(s) Line Width: 0.4 mm

Top/Bottom Line Width: 0.4 mm

Infill Line Width: 0.4 mm

Skirt/Brim Line Width: 0.4 mm

Support Line Width: 0.4 mm

Initial Layer Line Width: 100%

Shell

Wall Thickness: 0.8 mm

Wall Line Count: 2

Outer Wall Wipe Distance: 0.3 mm

Top Surface Skin Layers: 0

Top/Bottom Thickness: 0.6 mm

Top Thickness: 0.6 mm

Top Layers: 5

Bottom Thickness: 0.6 mm

Bottom Layers: 5

Initial Bottom Layers: 5

Top/Bottom Pattern: Lines

Bottom Pattern Initial Layer: Lines

Top/Bottom Line Directions: [ ]

Outer Wall Inset: 0 mm

Optimize Wall Printing Order: Check

Compensate Wall Overlaps: Check

Compensate Inner Wall Overlaps: Check

Minimum Wall Flow: 0%

Fill Gaps Between Walls: Everywhere

Filter Out Tiny Gaps: Check

Horizontal Expansion: 0 mm

Initial Layer Horizontal Expansion: 0 mm

Hole horizontal expansion: 0

Z Seam Alignment: User Specified

Z Seam Position: Back

Z Seam X: Average length of your printer’s plate (e.g.”150” if your plate is 300mmon the X-axis)

Z Seam Y: A value higher than the length of your plate on the Y-axis (e.g. 700)

Seam Corner Preference: Hide Seam

Extra Skin Wall Count: 1

Skin Overlap Percentage: 10%

Skin Overlap 0.04 mm

Infill

Infill Density: 20% (for all smaller parts and for all parts of connectors use 100% Infill)

Infill Pattern: Triangles

Connect Infill Lines: Check

Infill Line Directions: [ ]

Infill X Offset: 0 mm

Infill Y Offset: 0 mm

Infill Line Multiplier: 1

Extra Infill Wall Count: 0

Infill Overlap Percentage: 10-20%

Infill Overlap: 0.04 mm

Skin Overlap Percentage: 5%

Skin Overlap: 0.02 mm

Infill Wipe Distance: 0 mm

Infill Layer Thickness: 0.24 mm

Gradual Infill Steps: 0

Infill Before Walls: Check

Minimum Infill Area: 0 mm2

Skin Removal Width: 0.8 mm

Top Skin Removal Width: 0.8 mm

Bottom Skin Removal Width: 0.8 mm

Skin Expand Distance: 0.8

Top Skin Expand Distance: 0.8

Bottom Skin Expand Distance: 0.8

Maximum Skin Angle for Expansion: 90˚

Minimum Skin Width for Expansion: 0.0

Skin Edge Support Thickness: 0

Skin Edge Support Layers: 0

Material

Initial Layer Flow: 100%

Printing Temperature: See your filament settings

Initial Printing Temperature: Your filament settings

Final Printing Temperature: Your filament settings

Build Plate Temperature: Your filament settings

Build Plate Temperature Initial Layer: Your filament settings + 5°

Flow: 100% (Important! If you face difficulty printing the model, you may need to adjust the Flow parameter. You may research the topic using the Internet or seek assistance at our Customer Support Team at support@gambody.com)

Speed

You can increase the printing Speed by 20% when you print simple objects. For small/thin parts you need to decrease the Speed by 25% - 50%.

Print Speed: 50 mm/s

Infill Speed: 50 mm/s

Wall Speed: 25 mm/s

Outer Wall Speed:25 mm/s

Inner Wall Speed: 50 mm/s

Top/Bottom Speed: 25mm/s

Support Speed: 25 mm/s

Support Infill Speed: 45 mm/s

Support Interface Speed: 25 mm/s

Support Roof Speed: 25 mm/s

Support Floor Speed: 25 mm/s

Travel Speed: 80 mm/s

Initial Layer Speed: 80 mm/s

Initial Layer Print Speed: 20 mm/s

Initial Layer Travel Speed: 80 mm/s

Skirt/Brim Speed: 20 mm/s

Z Hop Speed: 5 mm/s

Number of Slower Layers: 2

Enable Acceleration Control: Check

When printing simple objects, you need to set all Acceleration parameters at 500 mm/s. For small/thin parts you need to decrease the Acceleration by 50% - 70%.

Travel

Enable Retraction: Check

Retraction Distance: 4-8 mm, 1-3 mm for Direct Extruder (This is the most important retraction parameter. You can find your optimal value of Retraction Distance by printing any test object, e.g. bridges, towers etc.)

Retraction Speed: 25mm/s

Retraction Retract Speed: 25 mm/s

Retraction Prime Speed: 25 mm/s

Retraction Extra Prime Amount: 0 mm3

Retraction Minimum Travel: 1.5 mm

Maximum Retraction Count: 100

Minimum Extrusion Distance Window: 6,5 - 10 mm

Limit Support Retractions: Check

Combing Mode: All

Max Comb Distance With No Retract: 30 mm

Retract Before Outer Wall: Check

Avoid Printed Parts When Travelling: Check

Avoid Supports When Travelling: Check

Travel Avoid Distance: 1 mm

Layer Start X: 0.0 mm

Layer Start Y: 0.0 mm

Z Hop When Retracted: Check

Z Hop Height: 0,3 mm

Cooling

Enable Print Cooling: Check

Fan Speed: 100%

Regular Fan Speed: 100%

Maximum Fan Speed: 100%

Regular/Maximum Fan Speed Threshold: 10 s

Initial Fan Speed: 0%

Regular Fan Speed at Height: 0.36 mm

Regular Fan Speed at Layer: 3

Minimum Layer Time: 10 s

Minimum Speed: 10 mm/s

Support

Generate Support: Check

Support Structure: Normal (you can try using Tree Support Structure if you have difficulty printing any particular assembly part)

Support Placement: Everywhere

Support Overhang Angle: 60° (this parameter can range from 30° to 70° depending on the part at hand)

Support Pattern: Zig Zag

Support Wall Line Count: 1 (stronger support that might be more difficult to remove) 0 (less strong support but is easier to remove)

Support Density: 15%

Support Line Distance: 2.6667 mm

Initial layer support line distance: 2.667 mm

Support Z Distance: 0.12 mm

Support Top Distance: 0.12 mm

Support Bottom Distance: 0.12 mm

Support X/Y Distance: 0.8-1 mm

Support Distance Priority: Z overrides X/Y

Support Stair Step Height: 0.3 mm

Support Stair Step Maximum Width: 5.0 mm

Support Stair Step Minimum Slope Angle: 10°

Support Join Distance: 2.0 mm

Support Horizontal Expansion: 0.2 mm

Support Infill Layer Thickness: 0.2 mm

Gradual Support Infill Steps: 0

Minimum Support Area: 2 mm

Enable Support Interface: Check (generates additional “pillow” on the support structure that leads to a more even surface, but can be difficult to remove in hard-to-reach areas)

Enable Support Roof: Check

Enable Support Floor: Check

Support Interface Thickness: 0.8 mm

Support Roof Thickness: 0.8 mm

Support Floor Thickness: 0.8 mm

Support Interface Resolution 0.2 mm

Support Interface Density: 50-100%

Support Roof Density: 50-100%

Support Roof Line Distance: 0.8 mm

Support Floor Density: 50-100%

Support Floor line Distance: 0.4mm

Support Interface Pattern: Grid

Support Roof Pattern: Grid (this parameter should differ from Bottom Pattern Initial Layer in “Shell” section)

Support Floor Pattern: Grid

Minimum Support Interface Area: 10mm

Minimum Support Roof Area: 10 mm

Minimum Support Floor Area: 10 mm

Support Interface Horizontal Expansion: 0.0 mm

Support Roof Horizontal Expansion: 0.0 mm

Support Floor Horizontal Expansion: 0.0 mm

Fan Speed Override: Check

Supported Skin Fan Speed: 100%

Use Towers: Check

Tower Diameter: 4 mm

Minimum Diameter: 3.0 mm

Tower Roof Angle: 65°

Build Plate Adhesion

Build Plate Adhesion Type: Skirt/Brim (For unsteady parts, and those parts that may come unstuck use “Brim”. For bigger assembly parts that have large adhesion area and for all parts of locks and claws that you want to come out clean use "Skirt")

Skirt/Brim Minimum Length: 250 mm

Brim Width: 8.0 mm

Brim Line Count: 10

Brim Only on Outside: Check

Mesh Fixes

Union Overlapping Volumes: Check

Merged Meshes Overlap: 0.15 mm

Special Modes

Print Sequence: All at Once

Surface Mode: Normal

Experimental

Slicing Tolerance: Middle

Maximum Resolution: 0.01 mm

Flow rate compensation max extrusion offset: 0 mm

Flow rate compensation factor: 100%

Simplify3D printing recommendations:

This model was tested with PLA material.

To avoid printing problems, we recommend the following settings:

Extruder

Nozzle Diameter: 0.4 mm

Extrusion Multiplier: 0.97

Extrusion Width: Auto

Retraction Distance: 5.00 mm

Extra Restart Distance: 0.00 mm

Retraction Vertical Lift: 0.08 mm

Retraction Speed: 5400.0 mm/min

Wipe Distance: 5.00 mm

Layer

Primary Layer Height: 0.2 mm

Top Solid Layers: 8

Bottom Solid Layers: 5

Outline/Perimeter Shells: 2

Outline Direction: Inside-Out

First Layer Height: 90%

First Layer Width: 100%

First Layer Speed: 20%

Additions

Use Skirt/Brim: Check

Skirt Layers: 1

Skirt Offset from Part: 6.00 mm

Skirt Outlines: 5

Infill

Internal Fill Pattern: Fast Honeycomb

External Fill Patern: Rectilinear

Interior Fill Percentage: 10%

Outline Overlap: 22%

Infill Extrusion Width: 100%

Minimum Infill Length: 5.00 mm

Combine Infill Every: 1 layers

External Infill Angle Offsets: 45/-45 deg

Support

Generate Support Material: Check

Support Infill Percentage: 15%

Extra Inflation Distance: 1.00 mm

Support Base Layers: 0

Combine Support Every: 1 layers

Dense Support Layers: 0

Dense Infill Percentage: 70%

Support Type: Normal

Support Pillar Resolution: 5.00 mm

Max Overhang Angle: 60 deg

Horizontal Offset From Part: 0.50 mm

Upper Vertical Separation Layers: 1

Lower Vertical Separation Layers: 1

Support Infill Angles: 45 deg

Temperature

Extruder 1 Temperature: 210

Heated Bed: 60

Cooling

Increase fan speed for layers below: 45.0 sec

Maximum Cooling fan speed: 50%

Bridging fan speed override: 100%

Speeds

Default Printing Speed: 4800.0 mm/min

Outline Underspeed: 50%

Solid Infill Underspeed: 80%

Support Structure Underspeed: 80%

X/Y Axis Movement Speed: 10800.0 mm/min

Z Axis Movemen Speed: 1002.0 mm/min

Adjust printing speed for layers below: 15.0 sec

Allow speed reduction down to: 20%

Other

Unsupported area threshold: 20.0 sq m

Slic3r printing recommendations:

Layer height

Layer height: 0.1 mm

First layer height: 90%

Vertical shells

Perimeters: 2

Horizontal shells

Soid layers:

Top: 8

Bottom: 5

Quality

Detect thin walls: Check

Detect bridging perimeters: Check

Advanced

Seam position: Random

Infill

Fill desity: 20%

Fill pattern: Honeycomb

Top/bottom fill pattern: Rectilinear

Reducing printing time

Combine infill every: 1 layers

Advanced

Solid infill every: 0 layers

Fill angle: 25 deg

Solid infill threshold area: 0mm

Skirt

Loops: 2

Distance from object: 6 mm

Skirt height: 1 layers

Minimum extrusion length: 4 mm

Brim

Brim width: 10 mm

Support material

Generate support material: Check

Overhang threshold: 45 deg

Enforce support for the first: 3 layers

Raft

Raft layers: 0 layers

Options for support material and raft

Contact Z distance: 0.1 mm

Pattern: Rectilinear

Patter spacing: 2 mm

Pattern angle: 0 deg

Interface layers: 2 layers

Interface pattern spacing: 0.2 mm

Speed for print moves

Perimeters: 60 mm/s

Small perimeters: 20 mm/s

External perimeters: 20 mm/s

Infill: 60 mm/s

Solid infill: 60 mm/s

Top solid infill: 30 mm/s

Support material: 50 mm/s

Support material interface: 100%

Bridges: 30 mm/s

Gap fill: 50 mm/s

Speed for non-print moves

Travel: 60 mm/s

Modifiers

First layer speed: 30 mm/s

Acceleration control

Perimeters: 800 mm/s

Infill: 1500 mm/s

Bridge: 1000 mm/s

First layer: 1000 mm/s

Default: 1000 mm/s

Autospeed

Max print speed: 100 mm/s

Max volumetrix speed: 0 mm/s

Extrusion width

Default extrusion width: 0.42 mm

First layer: 0.42 mm

Perimeters: 0.42 mm

External perimeters: 0.42 mm

Infill: 0.42 mm

Solid infill: 0.42 mm

Top solid infill: 0.42 mm

Support material: 0.42 mm

Overlap

Infill/Perimeters overlap: 20%

Flow

Bridge flow ratio: 0.95

Other

XY Size Compensation: 0 mm

Threds: 8

Resolution: 0 mm