Files

3D model format

Stereolithography (.stl)

Total files

Slicer settings

not available

Mesh error check

not specified

Support

Lifetime support from Gambody team

Update requests

not specified

Model versions

FFF/FDM

Assembly method

not specified

Features

DLP/SLA

Assembly method

not specified

Features

Additional details

Part of diorama

No

Special pack included

No

You will get instant access to the STL files of MWO Phoenix Hawk 3D Printing Files | Assembly + Action after completing your purchase. Simply add the model to your cart and check out using PayPal, credit or debit card, Apple Pay, Google Pay, Alipay, or other available payment methods.

Watch the assembly video for MWO Phoenix Hawk 3D Printing Files | Assembly + Action, and explore more tutorials, behind-the-scenes content, 3D printing timelapses, and painting guides on the official Gambody YouTube channel.

This 3D model consists of files in StereoLithography (.Stl) format that have been optimized for 3D printing.

Before printing the files, we strongly recommend reading the PRINTING DETAILS section.

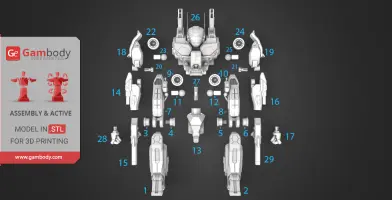

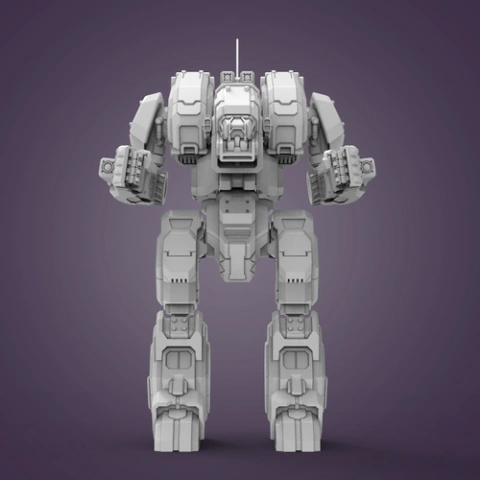

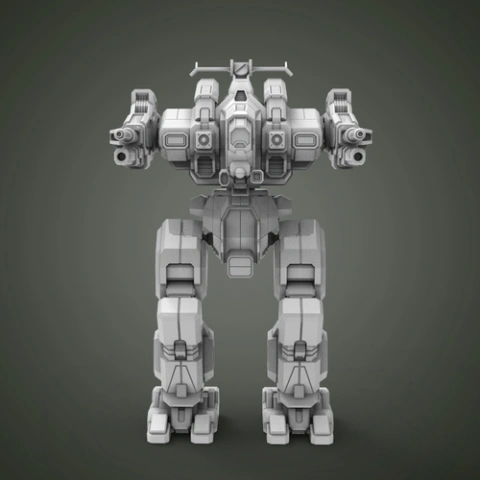

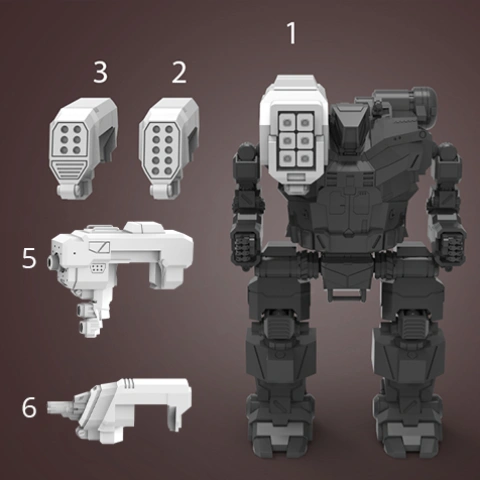

Version 1 and Version 2 are the files for Phoenix Hawk 3D model optimized for 3D printing, the preview pictures of which you see above.

It is recommended:

- to print Version 1 STL files on FDM/FFF 3D printers;

- to print Version 2 STL files on DLP/SLA/SLS 3D printers.

Before printing, take a look at Printing Details for recommended settings and tips to achieve better results.

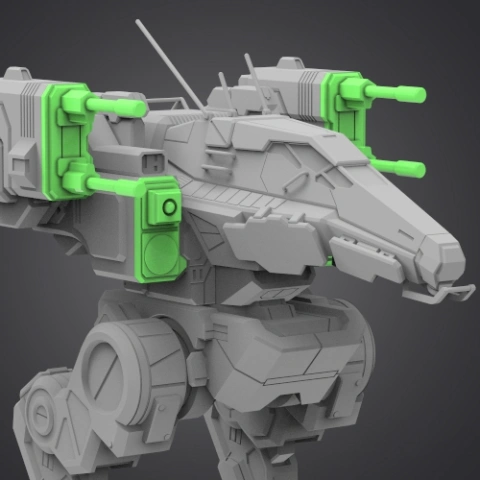

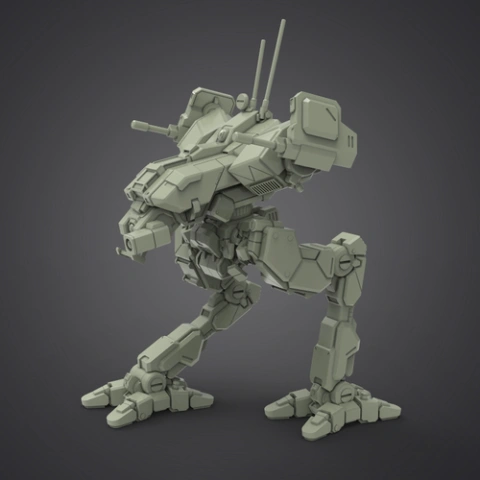

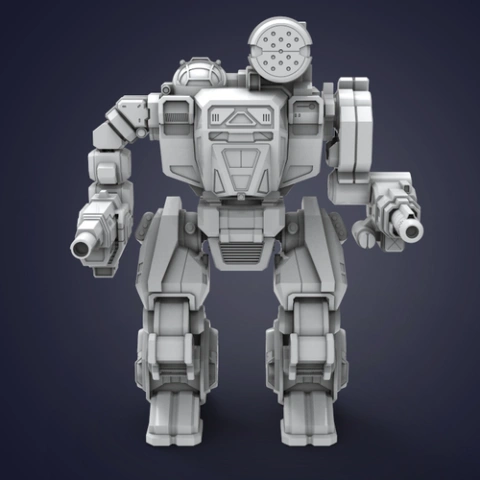

August at Gambody can surely be called MechWarrior Online month. Meet Phoenix Hawk Mech 3D Printing Miniature - new assembly and action model inspired by this game.

Phoenix Hawk was created and introduced by Terran Hegemony in year 2568. It pretends to be the most popular mech of Stinger class. Actually, it is considered to be a technically improved one. Phoenix Hawk combines the maneuverability, that is the feature of the class it belongs, with improved firepower and superior armor.

This mech can fight at different positions - in a front line, in command or in reconnaissance. As a weapon Phoenix Hawk uses two M100 Heavy Machine Guns. Its armouring is also a technical masterpiece, which is displayed in this design.

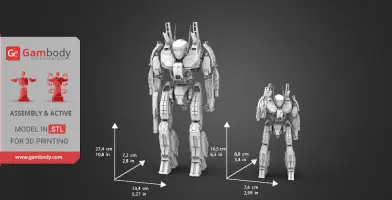

Both FDM and SLS/SLA versions are available. The real size of Phoenix Hawk is considered to be 14,5m without shoulder guns and 16,5m with them.

FDM version:

- Is 1:60 scale and after being printed will stand 241mm without shoulder guns and 275mm with them;

- Is designed to save almost all movable elements its prototype has;

- Has removable hinges that should be printed with 100% fill to make them solid.

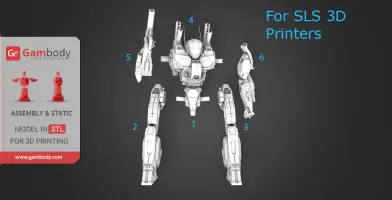

SLS/SLA version:

- Is 1:100 scale and will stand 145mm high if to print without antennas and 165mm if to print with them;

- Has as little details as possible to keep printing budget about 50-60 $.

Watch the tutorial video on how to assemble Phoenix Hawk Mech 3D Printing Miniature at Gambody YouTube channel.

Buy Phoenix Hawk Mech 3D Printing Miniature right now! Just click the green Buy button in the top-right corner of the model’s page. You can pay with PayPal or your credit card.

By the way, you can find male and female pilots 3d printing miniatures at Gambody, which will look awesome nearby your mech.

________________________

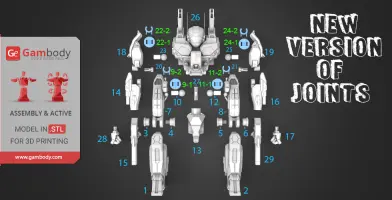

On 06.11.2017 new version of joints have been added.

To use new joints, you do not need to reprint the whole model of your Mech!

You can find detailed picture guidelines about how to use new joints in your modelHERE.

With the new joints you will get next advantages:

- Increases frictional force

- Possible to up scale or down scale the whole model

- Printable from any type of material

- Higher strength

- Material shrinkage does not affect at strength and friction

STL files are already available for download in “Source files” tab for Version 1 (FDM/FFF 3D printers). You can find them at the end of the list.

_______

FAQ:

Where can I print a model if I have no printer?

How to get started with 3D printing?

How to set up my 3D printer?

How to choose right 3D model print bed positioning?

How to paint printed figurine?

Average customer rating (5 reviews)

4.4

Ratings breakdown

Click a star rating to filter reviews

Overall experience

Level of detail in the model

4.4

Model cut quality and assembly guide

4.4

Clarity and accuracy of the model page

4.4

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

2

Model cut quality and assembly guide

2

Clarity and accuracy of the model page

2

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

To avoid printing issues and achieve the best quality, we highly recommend applying the following settings:

Generic

This model was tested in Cura 2.7.0. and print on an Ultimaker 2 in PLA material.

Note:

- You can print new joints with 20-30% infill.

- With the new joints you can up scale or down scale the whole model.

- All parts of connectors should be printed at 100% infill.

- You should print old joints with 100% infill.

- With the old joints do not try to up scale or down scale the whole model since it will not be assemble or movable after scale changes.

- Using the PLA material you should increase the scale of old joints at 2-3% in your slicing program.

- Using the ABS/CPE material you should increase the scale of old joints at 1% in your slicing program.

To avoid printing problems, we recommend the following settings:

Quality

Layer Height: 0.1 mm

Initial Layer Height: 0.3 mm

Line Width: 0.4 mm

Wall Line Width: 0.4 mm

Outer Wall Line Width: 0.4 mm

Inner Wall(s) Line Width: 0.4 mm

Top/Bottom Line Width: 0.4 mm

Infill Line Width: 0.4 mm

Skirt/Brim Line Width: 0.4 mm

Support Line Width: 0.4 mm

Initial Layer Line Width: 100%

Shell

Wall Thickness: 0.8 mm

Wall Line Count: 2

Outer Wall Wipe Distance: 0.2 mm

Top Surface Skin Layers: 0

Top/Bottom Thickness: 0.8 mm

Top Thickness: 0.8 mm

Top Layers: 8

Bottom Thickness: 0.8 mm

Bottom Layers: 8

Top/Bottom Pattern: Lines

Bottom Pattern Initial Layer: Lines

Top/Bottom Line Directions: [ ]

Outer Wall Inset: 0 mm

Compensate Wall Overlaps: Check

Compensate Outer Wall Overlaps: Check

Compensate Inner Wall Overlaps: Check

Fill Gaps Between Walls: Everywhere

Horizontal Expansion: 0 mm

Initial Layer Horizontal Expansion: 0 mm

Z Seam Alignment: Shortest

Ignore Small Z Gaps: Check

Infill

Infill Density: 20%

Infill Line Distance: 3.5 mm

Infill Pattern: Grid

Infill Line Directions: [ ]

Infill Overlap Percentage: 10%

Infill Overlap: 0.4 mm

Skin Overlap Percentage: 5%

Skin Overlap: 0.02 mm

Infill Wipe Distance: 0.1 mm

Infill Layer Thickness: 0.1 mm

Gradual Infill Steps: 0

Infill Before Walls: Check

Minimum Infill Area: 0 mm2

Material

Enable Retraction: Check

Retraction Extra Prime Amount: 0 mm3

Retraction Minimum Travel: 0.8 mm

Maximum Retraction Count: 90

Minimum Extrusion Distance Window: 6.5 mm

Nozzle Switch Retraction Distance: 20 mm

Nozzle Switch Retraction Speed: 20 mm/s

Nozzle Switch Retract Speed: 20 mm/s

Nozzle Switch Prime Speed: 20 mm/s

Speed

Print Speed: 50 mm/s

Infill Speed: 50 mm/s

Wall Speed: 40 mm/s

Outer Wall Speed: 30 mm/s

Inner Wall Speed: 40 mm/s

Top/Bottom Speed 20 mm/s

Support Speed: 30 mm/s

Support Infill Speed: 30 mm/s

Travel Speed: 120 mm/s

Initial Layer Speed: 30 mm/s

Initial Layer Print Speed: 30 mm/s

Initial Layer Travel Speed: 72 mm/s

Skirt/Brim Speed: 30 mm/s

Maximum Z Speed: 0 mm/s

Number of Slower Layers: 2

Travel

Combing Mode: All

Avoid Printed Parts when Traveling: Check

Travel Avoid Distance: 0.6562 mm

Cooling

Enable Print Cooling: Check

Fan Speed: 100%

Regular Fan Speed: 100%

Maximum Fan Speed: 100%

Regular/Maximum Fan Speed Threshold: 10 s

Initial Fan Speed: 0%

Regular Fan Speed at Height: 0.27 mm

Regular Fan Speed at Layer: 2

Minimum Layer Time: 5 s

Minimum Speed: 10 mm/s

Support

Enable Support: Check

Support Placement: Everywhere

Support Overhang Angle: 50°

Support Pattern: Zig Zag

Connect Support ZigZags: Check

Support Density: 15 %

Support Line Distance: 2.3333 mm

Support Z Distance: 0.15 mm

Support Top Distance: 0.15 mm

Support Bottom Distance: 0.15 mm

Support X/Y Distance: 0.8 mm

Support Distance Priority: Z overrides X/Y

Minimum Support X/Y Distance: 0.2 mm

Support Stair Step Height: 0.3 mm

Support Stair Step Maximum Width: 5.0 mm

Support Join Distance: 2.0 mm

Support Horizontal Expansion: 0.2 mm

Support Infill Layer Thickness: 0.1 mm

Use Towers: Check

Tower Diameter: 3.0 mm

Minimum Diameter: 3.0 mm

Tower Roof Angle: 65°

Build Plate Adhesion

Build Plate Adhesion Type: Brim

Skirt/Brim Minimum Length: 250 mm

Brim Width: 8.0 mm

Brim Line Count: 15

Brim Only on Outside: Check

Mesh Fixes

Union Overlapping Volumes: Check

Merged Meshes Overlap: 0.15 mm

Special Modes

Print Sequence: All at Once

Surface Mode: Normal

Experimental

Extra Skin Wall Count: 0

Disclaimer: This model will look outstanding if printed on SLA/SLS 3D printer. The accuracy of the model printed on FFF printer can vary from the result shown in the pictures.