Files

3D model format

Stereolithography (.stl)

Total files

Slicer settings

not available

Mesh error check

not specified

Support

Lifetime support from Gambody team

Update requests

not specified

Model versions

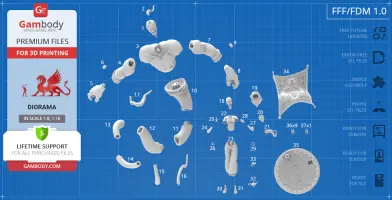

FFF/FDM

Assembly method

Connectors, Ge-Locks, Glue

Features

The assembly parts are connected using specially designed integrated connectors that fit securely into the corresponding slots. Some model parts use separate connectors (part "36_ge_lock_10H(x9)", requires 9 copies, and 37_ge_lock_7S(x1) needs to be printed once). Optionally, for added strength and rigidity, the static connections can be glued together;

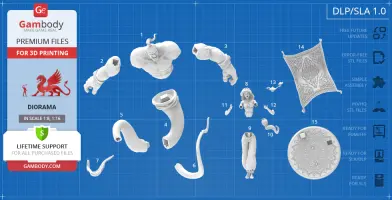

DLP/SLA

Assembly method

Connectors, Glue

Features

The assembly parts are connected using specially designed integrated connectors that fit securely into the corresponding slots. Optionally, for added strength and rigidity, the static connections can be glued together;

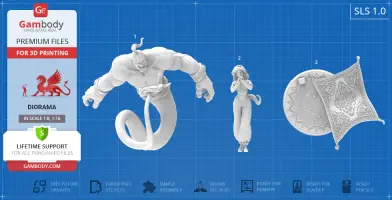

SLS

Assembly method

Connectors, Glue

Features

A one-piece Jasmine model and a solid Genie with the platform separated. The assembly parts are connected using specially designed integrated connectors that fit securely into the corresponding slots. Optionally, for added strength and rigidity, the static connections can be glued together;

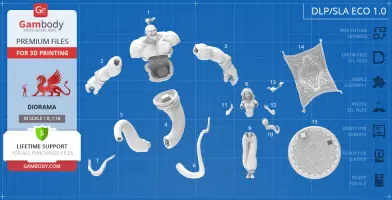

DLP/SLA

Assembly method

Connectors, Glue

Features

Some parts are hollowed out to save resin. The assembly parts are connected using specially designed integrated connectors that fit securely into the corresponding slots. Optionally, for added strength and rigidity, the static connections can be glued together;

Additional details

Part of diorama

No

Special pack included

No

You can get the STL files of Jasmine & Genie in Diorama immediately after the purchase! Just click the green Buy button in the top-right corner of the model’s page. You can pay with PayPal or your credit card.

Watch the tutorial on how to assemble the 3D printed Jasmine & Genie Diorama from the provided 3D Print Files at Gambody YouTube channel.

Also, you may like the other Cartoons 3D Printing Designs.

_______

FAQ:

This 3D model comes with StereoLithography (.STL) files optimized for 3D printing. You'll get digital files, not a physical product

Before printing, take a look at Printing Details for recommended settings and tips to achieve better results.

Jasmine & Genie in Diorama 3D Printer Files | Assembly includes 3 version(s) for the supported 3D printer type(s): FFF/FDM, DLP/SLA, SLS. Files are available for download after purchase.

See the Description and Specifications sections for more details about this model.

3D model history

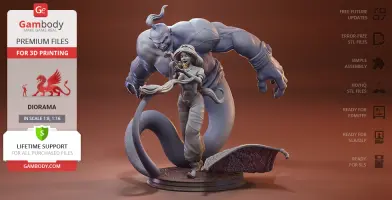

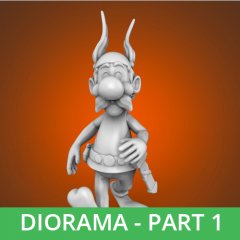

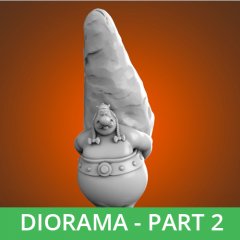

The 1992 Aladdin animated film made audiences of all ages fall in love with the adventures of a common thief, Sultan’s rebellious daughter and larger-than-life Genie. Loosely based on the character featured in the One Thousand and One Nights folk tale, Jasmine aspires to independence and dreams of seeing what's beyond her palace. Eccentric Genie, in his turn, possesses phenomenal cosmic power and longs to be freed from the magic lamp residence. The author of the Jasmine & Genie diorama got inspired by the Disney's well-loved classics. The 3D artists decided to capture the deuteragonists of the Aladdin franchise in 3D printing form and spent circa 180 hours sculpting the scene. The diorama depicts the beautiful Princess Jasmine holding the magic lamp whose prisoner seems to have been freed from the itty bitty living space mere moments ago. The rebellious princess of Agrabah looks astounded - the young lady clearly did not expect the wish-granting Genie to escape the simple oil lamp! The 3D printing Jasmine has her straight, lush hair pulled in a ponytail in two sections and wears the 1992 cartoon-inspired crop top, puffy pants and curled shoes. The usually kind-hearted Genie must have been in his mischievous mood while posing for the 3D printing diorama since the posture and the look on the model's face seem to aim at scaring the Princess. The flamboyant spirit for 3D printing spots the curly beard, high ponytail, wide waistband, and has his right ear pierced with an earring. Both 3D printing heroes are mounted on a simple round base that has an exquisite mandala pattern embossed on it. The whole dynamic scene is completed with a fine magic carpet, adorned with intricate patterns from both sides. We wonder what Jasmine’s first wish is going to be?

3D printing model features

Model-specific features:

- To conceal the places where the assembly parts of the model must be connected, the models were cut along the contour of both characters' clothes seams and they were properly separated from the platform;

- To ensure an excellent quality of the 3D printed result, such smaller parts as magic lamp, magic carpet, both models' hair, hands, jewels on Genie’s wrists, Jasmine's bracelets, lamp smokes, etc. are provided as separate assembly elements.

Printing & assembly details:

- Provided as error-free STL files compatible with most 3D printers;

- Optimized part division minimizes support material and ensures smooth surface detail;

- The assembly parts in the FFF/FDM version come in the recommended print orientations for easy bed placement;

- Assembly manual in PDF and video formats is included for both FFF/FDM and DLP/SLA versions;

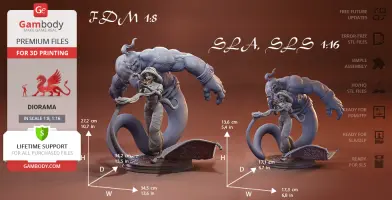

- The model is available in recommended scales of 1:8 for the FFF/FDM version and 1:16 for the DLP/SLA/SLS versions, based on approximate height of Jasmine (1700 mm).

What will you get after purchase?

- 4 versions of Jasmine & Genie STL files for FFF/FDM, DLP/SLA, DLP/SLA Eco, and SLS — files for all versions are available for download after the purchase;

- STL files of high-poly Jasmine & Genie diorama model for 3D printing consist of 70 files;

- Sizes for:

- FFF/FDM: 345 mm wide, 272 mm high, 342 mm deep;

- DLP/SLA/SLS: 173 mm wide, 136 mm high, 171 mm deep;

- Assembly Manual for FFF/FDM 1.0 and DLP/SLA 1.0 versions in PDF and video formats;

- Detailed settings that we provide as a recommendation for Bambu Studio, Cura, Orca Slicer, PrusaSlicer, Simplify3D, and Slic3r for the best print;

- Full technical support from the Gambody Support Team.

Average customer rating (5 reviews)

4.6

Ratings breakdown

Click a star rating to filter reviews

Overall experience

Level of detail in the model

4.6

Model cut quality and assembly guide

4.6

Clarity and accuracy of the model page

4.6

Level of detail in the model

3

Model cut quality and assembly guide

3

Clarity and accuracy of the model page

3

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

To avoid printing issues and achieve the best quality, we highly recommend applying the following settings:

Generic

Below you can find printing recommendations for Bambu Studio, Cura, Orca Slicer, PrusaSlicer, Simplify3D, and Slic3r software.

Disclaimer: The following printing settings are a recommendation, not an obligation. The parameters can vary depending on the peculiarities of your 3D printer, the material you use, and especially the particular assembly part you are working with. Each part that any model comprises often needs preliminary review, and you are free to tweak the settings the way you find suitable.

Note:

You can scale up the model (downscaling for FFF/FDM 3D printers is not recommended!);

All connectors should be printed at 100% Infill.

Bambu Lab printing recommendations:

These basic 3D printing settings recommendations for beginners were tested in Bambu Studio 1.9.1. Test models were printed on the Bambu Lab A1, Bambu Lab A1 Mini, Creality Ender 3 S1, Anycubic Kobra 2, and Anycubic Vyper using PLA and PETG filaments.

To avoid printing problems, we recommend the following settings:download

Cura printing recommendations:

These are averaged settings which were tested in the Cura 5.2.1 slicer. Test models were printed on Anycubic Vyper, Creality Ender 3 Pro with PLA filament.

To avoid printing problems, we recommend the following settings: download

Orca Slicer printing recommendations:

These basic 3D printing settings recommendations for beginners were tested in Orca Slicer 2.3.0. Test models were printed on Bambu Lab A1, Bambu Lab A1 Mini, Creality Ender 3 V3, and Anycubic Kobra 3 with PLA and PETG filament.

To avoid printing problems, we recommend the following settings: download

PrusaSlicer printing recommendations:

These basic 3D printing settings recommendations for beginners were tested in PrusaSlicer 2.3.1. Test models were printed on Ultimaker 2, Creality Ender 3, Creality Cr-10S pro v2, Anycubic I3 Mega, Anycubic I3 MegaS, Anycubic Vyper with PLA and PETG filaments.

To avoid printing problems, we recommend the following settings:download

Simplify3D printing recommendations:

These are averaged settings which were tested in the Simplify3D 5.0.0 slicer. Test models were printed on Anycubic Vyper, FLSUN v400, Ender3 S1 with PLA filament.

To avoid printing problems, we recommend the following settings:download

Slic3r printing recommendations:

These basic 3D printing settings recommendations for beginners were tested in Slic3r 1.3.0 software. Test models were printed on Ultimaker 2, Creality Ender 3, Creality Cr-10S pro v2, Anycubic I3 Mega, Anycubic I3 MegaS, Anycubic Vyper with PLA and PetG filaments.

To avoid printing problems, we recommend the following settings:download

SLS

A one-piece Jasmine model and a solid Genie with the platform separated. The assembly parts are connected using specially designed integrated connectors that fit securely into the corresponding slots. Optionally, for added strength and rigidity, the static connections can be glued together;

DLP/SLA

Some parts are hollowed out to save resin. The assembly parts are connected using specially designed integrated connectors that fit securely into the corresponding slots. Optionally, for added strength and rigidity, the static connections can be glued together;

DLP/SLA

The assembly parts are connected using specially designed integrated connectors that fit securely into the corresponding slots. Optionally, for added strength and rigidity, the static connections can be glued together;

FFF/FDM

The assembly parts are connected using specially designed integrated connectors that fit securely into the corresponding slots. Some model parts use separate connectors (part "36_ge_lock_10H(x9)", requires 9 copies, and 37_ge_lock_7S(x1) needs to be printed once). Optionally, for added strength and rigidity, the static connections can be glued together;