Files

3D model format

Stereolithography (.stl)

Total files

Slicer settings

Mesh error check

not specified

Support

Lifetime support from Gambody team

Update requests

not specified

Model versions

FFF/FDM

Assembly method

not specified

Features

FFF/FDM

Assembly method

not specified

Features

FFF/FDM

Assembly method

not specified

Features

FFF/FDM

Assembly method

not specified

Features

FFF/FDM

Assembly method

not specified

Features

FFF/FDM

Assembly method

not specified

Features

Additional details

Part of diorama

No

Special pack included

No

You will get instant access to the STL files of Fun Face Masks for 3D Printing | Assembly after completing your purchase. Simply add the model to your cart and check out using PayPal, credit or debit card, Apple Pay, Google Pay, Alipay, or other available payment methods.

Watch the assembly video for Fun Face Masks for 3D Printing | Assembly, and explore more tutorials, behind-the-scenes content, 3D printing timelapses, and painting guides on the official Gambody YouTube channel.

The 3D Models consist of files in StereoLithography (.stl) format that is optimized for 3D printing and upon request can be additionally provided in Maya Binary scene (.mb) files that can be opened by AutoDesk Maya software.

Before printing the files, we strongly recommend reading the PRINTING DETAILS section.

Each 3D Printing Face Mask comes in a separate version for FFF/FDM 3D printer type. STL files for each 3D printing mask are available for download below. You can request .mb files of each mask by writing at support@gambody.com.

Detailed information about the 3D printing models is available in the DESCRIPTION section.

Before printing, take a look at Printing Details for recommended settings and tips to achieve better results.

ABOUT THIS 3D MODEL

In the time when the ongoing global pandemic is rapidly affecting all aspects of everyday life, it is of vital importance to stay socially responsible and preserve positive mindset for the sake of yourself and your dear ones. 3D printing community representatives from all across the globe have been demonstrating great initiatives to make a difference in the current situation. On our part, Gambody team wants to support and cheer up all 3D printing fans who are self-isolating at home, offering a fun way to entertain yourself and the ones you are is quarantining with. Fun face masks inspired by iconic fictional characters notable for their appearance may become an amusing pastime during social-distancing. You might have been puzzling over the theme Birthday party to throw in quarantine conditions with your folks or there might be an online video chat planned with your friends - the one-of-a-kind fun masks may, in fact, do their job in maintaining a good mood throughout the yet another day of quarantine. What is more, working on such a 3D printing project with your child will most likely result in an excellent quality time spend together. It is simply impossible to get bored while creating a life-size mask of a favourite video game hero! Last but not least, it is never to early to start your preparation for the next theme festival or even Comic-Con. The fun masks for 3D printing were prepared for all fans of our marketplace, all geeks, comic books enthusiasts and members of 3D printing community in order to show our support and to make sure all of you remember that you are never alone. Stay in the safety of your home, 3D print the mask of your beloved character and don’t let any blues into your quarantine!

DISCLAIMER: Please be aware that these 3D printing masks are non-medical, they have not been tested by medical professionals or verified by the appropriate regulatory. The design of these 3D printing masks is not intended to replace standard personal protective equipment as N-95 or surgical masks etc. but may become a basis for alternative protection in case of a nationwide shortage of PPE or if the conventional equipment becomes unavailable only if the maker is competent to undertake any modifications of this kind. These 3D printing masks are not meant to be worn as a protection during the pandemic but can be used as personal basic PPE by healthy people who are practising good social distancing and self-isolation in order to cheer up the household one is quarantining with. We strongly urge 3D printing enthusiasts not to use non-verified 3D printed masks as PPE in medical facilities and in crowded venues.

MASKS' DESIGN AND CHARACTERISTICS

Format. The masks are saved in STL files, a format supported by most 3D printers and in .mb format that one can open in AutoDesk Maya to modify the design (the latter are provided upon request being too large to come with STL files).

Material. You can print the masks using your regular PLA or PETG 3D printing filament or go for any flexible material of your choice to make the mask more comfortable to wear. We highly recommend that you avoid any toxic materials or filaments of questionable quality while printing your face mask.

Size and Adjustment. Each mask comes in 1:1 scale to fit an average adult face. Should you feel the need to adjust the shape of the mask to fit your face more snugly you can do it by applying high temperature and force (the masks are made 2-5mm thick to allow that), or contact us at support@gambody.com, indicating what particular areas feel wrong and our team will make the adjustments for you within the STL file. As mentioned above, there are also files in .mb format for you to modify the mask as you wish yourself that you can request by writing at support@gambody.com.

Ventilation and Hygiene. In order for one to freely breathe while wearing the mask, there were vent openings provided which have hollow areas meant for filters to make sure the air you are breathing is clean. Make sure you follow the personal hygiene rules while wearing the face mask!

N.B. If you choose to modify the design of any of these 3D printing face masks in order to use it as an alternative to the regular PPE, please, make sure you take into consideration the importance of the step-by-step processing of the 3D printed mask.

It is recommended to thoroughly (1) sand the surface of the mask under the tap water with progressively finer grits all the way to a smooth finish. (2) Add filler (spray or paste) all over the mask’s surface to make sure you fill all fine gaps between the layers. (3) Sand the mask again, this time without any water. (4) Cover the surface of the mask with thick coats of clear lacquer. (5) Use any rubber material (e.g. rubber window padding tape) to apply the rubber seal around the edge of the mask. Make sure you use non-toxic silicone or glue. (6) Seal the area around filters with re-usable o-rings, funky foam etc.

VERSIONS' SPECIFICATIONS

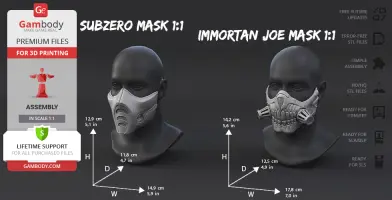

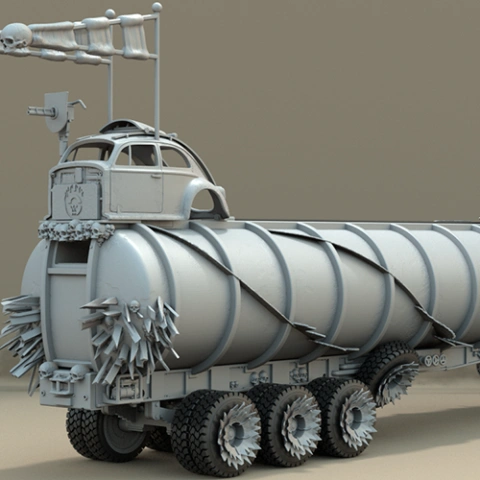

IMMORTAN JOE MASK 1.0 version features:- Contains 3 parts;- A printed mask is 142 mm tall, 178 mm wide, 125 mm deep;- Made to resemble character's trademark skeletal jawwith horse teeth and various metal areas;- Appears as if the hoses were removed and now the mask only has the respirator screws on either side of the teeth;

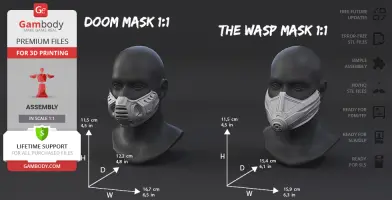

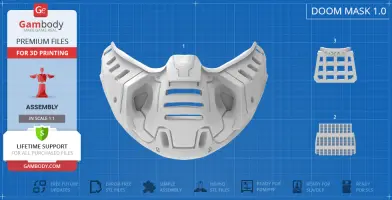

DOOM MASK 1.0 version features:- Contains 3 parts;- A printed model is 115 mm tall, 164 mm wide, 122 mm deep;- The helmet of Doom Slayer's 2016 Praetor Suit was used as a basis for the mask;

SUB-ZERO MASK 1.0 version features:- Contains 3 parts;- A printed model is 129 mm tall, 149 mm wide, 118 mm deep;- Made to resemble the character's iconic uniform mask inspired by his 2011 Mortal Kombat appearance;

THE WASP MASK 1.0 version features:- Contains 3 parts;- A printed model is 115 mm tall, 159 mm wide, 154 mm deep;- Made to resemble the bottom half of Wasp's oblong helmet inspired by 2018 Marvel Comics movie.

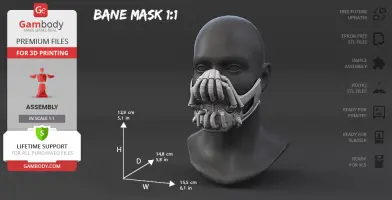

BANE MASK 1.0 version features:- Contains 4 parts;- A printed model is 129 mm tall, 155 mm wide, 148 mm deep;- Made to resemble the character's iconic mask inspired by Tom Hardy's performance in “The Dark Knight Rises”.

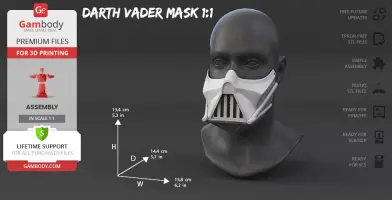

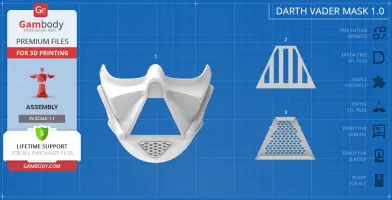

DARTH VADER MASK 1.0 version features:- Contains 3 parts;- A printed model is 134 mm tall, 158 mm wide, 144 mm deep;- Made to resemble the bottom half of the signature helmet of Darth Vader.

All Fun Face Masks for 3D Printing are Open Source Designs. You just need to add the item to your shopping cart and follow the free of the charge purchase procedure. Immediately after completing it, you can get the model of 3D Printing Fun Face Masks in the "Source files" tab! Just choose the version you prefer in the combo box. You can download all the STL files in a single action, or you can download each file separately. You can request .mb files of each mask by writing at support@gambody.com.

Watch the tutorial on how to assemble 3D Printing Fun Face Masks at Gambody YouTube channel.

_______FAQ: Where can I print a model if I have no printer?How to get started with 3D printing?How to set up my 3D printer?How to choose right 3D model print bed positioning? How to paint printed figurine?

Average customer rating (162 reviews)

4.5

Ratings breakdown

Click a star rating to filter reviews

Overall experience

Level of detail in the model

4.5

Model cut quality and assembly guide

4.5

Clarity and accuracy of the model page

4.5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

4

Model cut quality and assembly guide

4

Clarity and accuracy of the model page

4

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

3

Model cut quality and assembly guide

3

Clarity and accuracy of the model page

3

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

1

Model cut quality and assembly guide

1

Clarity and accuracy of the model page

1

Level of detail in the model

3

Model cut quality and assembly guide

3

Clarity and accuracy of the model page

3

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

4

Model cut quality and assembly guide

4

Clarity and accuracy of the model page

4

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

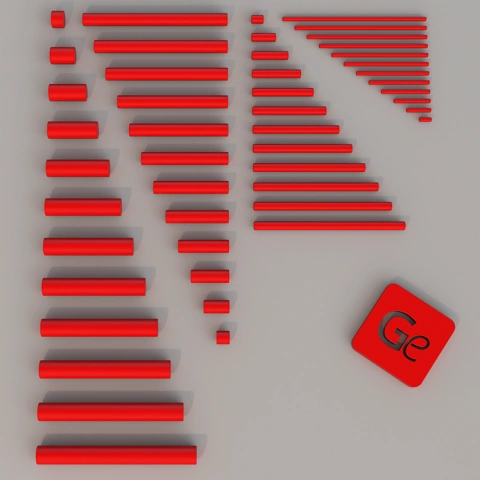

Below you'll find detailed slicing settings for Bambu Studio 2.0+, Orca Slicer 2.0+, UltiMaker Cura 5.0+, PrusaSlicer 2.0+, Slic3r 1.3+, Simplify3D 5.0+ to help you get the best results when printing this model. These settings are optimized specifically for this 3D model, but please note they may need slight adjustments depending on your printer or filament. When in doubt, refer to your printer's user manual.

To avoid printing issues and achieve the best quality, we highly recommend applying the following settings:

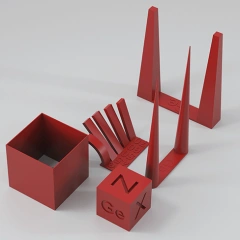

For better quality use 0.12 mm layer height, for fast printing use 0.2 mm layer height. For pins and the Ge connectors, use 0.2 layer height.

120-150% of your Layer Height

But you can paint the seam if you want.

You have to calibrate this parameter

You have to calibrate this parameter

You have to calibrate this parameter

For pins and power elements of the structure, such as the vehicle frame, use 3 loop

Disabled for vehicles and enabled for characters

For 0,2 Layer Height

The parameters in this tab vary greatly, it all depends on the quality of your printer. For example, if you have a classic Ender3, stick to the minimum parameters, but if you have a newer printer, for example Anycubic cobra 3 v2, you can select the maximum recommended values

Settings for advanced users, change these parameters only if you have sufficient 3D printing expertise

Enable this parameter if your model requires supports

We also recommend placing and removing supports manually in some places using special button

1-2 loops for more thick support

Top Z distance = 1-1.3 layer Height. If the supports are hard to remove, try increasing this setting by 0.1-0,4 mm

Bottom Z distance = 1-1.3 layer Height. If the supports are hard to remove, try increasing this setting by 0.1-0,4 mm

You have to calibrate this parameter which one is better for your filament

Increase this parameter if the supports are hard to remove from walls

For PLA and PETG filament types

5-8 mm is optional for small prints that have bad adhesion to the build plate

You have to calibrate this parameter

Read the description on your filament roll

Read the description on your filament roll and increase this parameter for fast printers

Read the description on your filament roll and increase this parameter for fast printers

For better quality use 0.12 mm layer height, for fast printing use 0.2 mm layer height. For pins and the Ge connectors, use 0.2 layer height.

120-150% of your Layer Height

But you can paint the seam if you want.

0.01-0.05 You have to calibrate this parameter

0.01-0.05 You have to calibrate this parameter

0.1-0.2 You have to calibrate this parameter

For pins and power elements of the structure, such as the vehicle frame, use 3 loop

Disabled for vehicles and ships, enabled for characters

For 0,2 Layer Height

For 0,2 Layer Height

The parameters in this tab vary greatly, it all depends on the quality of your printer. For example, if you have a classic Ender3, stick to the minimum parameters, but if you have a newer printer, for example, Anycubic Kobra 3 Or Bambulab A1, you can select the maximum recommended values.

Settings for advanced users, change these parameters only if you have sufficient 3D printing expertise

Enable this parameter if your model requires supports

We also recommend placing and removing supports manually in some places using special button

Top Z distance = 1-1.3 layer Height. If the supports are hard to remove, try increasing this setting by 0.1-0,4 mm

Bottom Z distance = 1-1.3 layer Height. If the supports are hard to remove, try increasing this setting by 0.1-0,4 mm

Increase this parameter if the supports are hard to remove from walls

For PLA and PETG filament types

5-8 mm is optional for small prints that have bad adhesion to the build plate

Read the description on your filament roll

Read the description on your filament roll and increase this parameter for fast printers

You have to calibrate this parameter

Read the description on your filament roll and increase this parameter for fast printers

Read the description on your filament roll

This field is filled in according to your printer specifications when you add it to the slicer.

You can add custom G-code here for the start and end of the print. However, be careful - this is for advanced users only!

You have to calibrate your printer using Ge retraction test models

Retraction Length: For direct-drive setups use 0.5 mm to 2.5 mm; for Bowden extruders use 5 to 7 mm

This is how fast the filament is pulled back—40-60 mm/s for direct drive and 30-50 mm/s for Bowden setups.

You have to calibrate this parameter: Reduce it until the printer starts to hit the parts with the nozzle during printing, then increase it by 0.2.

For better quality use 0.12 mm layer height, for fast printing use 0.2 mm layer height. For pins and the Ge connectors, use 0.2 layer height.

120-150% of your Layer Height

To increase the strength of the print parts, use wall line count: 3

For pins and connectors use 50% Infill

These parameters are for standard PLA plastic. If you are using a different type of plastic, check the printing temperature recommended by the manufacturer. Also, read the description on your filament spool. For fast printers, add +30 °C to the current parameters.

The parameters in this tab vary greatly, it all depends on the quality of your printer. For example, if you have a classic Ender3, stick to the minimum parameters, but if you have a newer printer, for example Anycubic cobra 3 v3, you can select the maximum recommended values

Settings for advanced users, change these parameters only if you have sufficient 3D printing expertise.

You need to calibrate this parameter using Gambody test models. These values are average values for a Direct Drive extruder; for a Bowden extruder, the values should be increased.

You need to calibrate this parameter using Gambody test models. These values are average values for a Direct Drive extruder; for a Bowden extruder, the values should be increased.

Use this value other than 0 if your nozzle catches on the internal infill during travel moves. Try to keep this value as low as possible in height.

Use normal supports to support large, straight surfaces (most mechanical or technical parts).

You have to calibrate this parameter according to the capabilities of your printer and your filament, using a Gambody test models.

Use 1 instead of 0 if your supports are thin and tall. They will be harder to remove, but much stronger.

Top Z distance = 1-1.3 layer Height. If the supports are hard to remove, try increasing this setting by 0.1-0,4 mm

Increase this parameter if the supports are hard to remove from walls

Use tree supports to support complex objects, such as characters.

You have to calibrate this parameter according to the capabilities of your printer and your filament, using a Gambody test models.

Top Z distance = 1-1.3 layer Height. If the supports are hard to remove, try increasing this setting by 0.1-0,4 mm

Increase this parameter if the supports are hard to remove from walls

Use a skirt for all parts when printing on outdated printers.

Use a brim when printing thin but tall parts, as well as parts with a small bed adhesion area.

For better quality use 0.12 mm layer height, for fast printing use 0.2 mm layer height. For pins and the Ge connectors, use 0.2 layer height.

120-150% of your Layer Height

for 0.2 Layer Height

But you can paint the seam if you want.

(for PLA and PETG)

(5-8 mm is optional for small prints that have bad adhesion to the build plate)

Enable this parameter if your model requires supports

(45-50 degree)You have to calibrate this parameter according to the capabilities of your printer

and your filament, using a Gambody test models.

Top contact Z distance = 1-1.3 layer Height. If the supports are hard to remove, try

increasing this setting by 0.1-0,4 mm

Top contact Z distance = 1-1.3 layer Height. If the supports are hard to remove, try

increasing this setting by 0.1-0,4 mm

Increase this parameter if the supports are hard to remove from walls

The parameters in this tab vary greatly, it all depends on the quality of your printer. For example, if you have a classic Ender3, stick to the minimum parameters, but if you have a newer printer, for example Anycubic cobra 3 v3, you can select the maximum recommended values

Settings for advanced users, change these parameters only if you have sufficient 3D printing expertise. Use the minimum value for outdated printers without acceleration calibration, and the maximum value for modern printers if you need it.

These settings only work for 3D printers with multiple extruders

You can try setting all parameters in this section, except the First layer, to values between 0.75% of your nozzle diameter and 1.25% of your nozzle diameter. Adjusting them will help you work out the optimal parameters for the best quality for your print. As for the First layer, you can set it to 150% of the diameter of your nozzle for better adhesion to the build plate (for a nozzle with a diameter of 0.4 mm, the First layer extrusion width can be from 0.3 mm to 0.5 mm)

For better printing quality you have to calibrate this parameter using Gambody test model.

Check your filament manufacturer's temperature recommendations on the spool.

Cooling parameters depends on the material you use for printing.

*for PLA

For better quality use 0.12 mm layer height, for fast printing use 0.2 mm layer height. For pins and the Ge connectors, use 0.2 layer height.

120-150% of your Layer Height

For 0.12 Layer Height

For 0.12 Layer Height

For pins and connectors use 50% Infill

Use skirt for outdated 3d printers

(5-8 mm is optional for small prints that have bad adhesion to the build plate)

Enable this parameter if your model requires supports

(45-60 degree)You have to calibrate this parameter according to the capabilities of your printer and your filament, using a Gambody test models

Contact Z distance = 1-1.3 layer Height. If the supports are hard to remove, try increasing this setting by 0.1-0,4 mm

The parameters in this tab vary greatly, it all depends on the quality of your printer. For example, if you have a classic Ender3, stick to the minimum parameters, but if you have a newer printer, for example Anycubic cobra 3 v3, you can select the maximum recommended values

Settings for advanced users, change these parameters only if you have sufficient 3D printing expertise. Use the minimum value for outdated printers without acceleration calibration, and the maximum value for modern printers if you need it.

You have to calibrate this parameter from 0.9 to 1.1 according to the capabilities of your printer and your filament, using a Gambody test models.

Check your filament manufacturer's temperature recommendations on the spool.

Cooling parameters depends on the material you use for printing.

Calibrate this value if you need to reduce or improve the adhesion between the plastic and the heat bed

Your current nozzle diameter

You need to calibrate this parameter using Gambody test models. These values are average values for a Direct Drive extruder; for a Bowden extruder, the values should be increased.

Your current nozzle diameter

You have to calibrate this parameter using Gambody test models.

You need to calibrate this parameter using Gambody test models. These values are average values for a Direct Drive extruder; for a Bowden extruder, the values should be increased.

For better quality use 0.12 mm layer height, for fast printing use 0.2 mm layer height. For pins and the Ge connectors, use 0.2 layer height.

For 0,2 Layer Height

For 0,2 Layer Height

To increase the strength of the print parts, use Outline Perimeters: 3

You can enable this parameter to print rounded or spherical models, as well as character models.

Use this option only if your parts are too tight. but better calibrate your printer extrusion

Use this option only if your parts are too tight. but better calibrate your printer extrusion

Use 2 and more if you want to create skirt instead brim

1-2 for skirt and 10-20 for brim

Use for wipe nozzle if you need

Use For ABS filament

For pins and connectors use 50% Infill

Top Z distance = 1-1.3 layer Height. If the supports are hard to remove, try increasing this setting by 0.1-0,4 mm

Calibrate your filament and detect optimal temperature for it

Average temperature for PLA filament

The parameters in this tab vary greatly, it all depends on the quality of your printer. For example, if you have a classic Ender3, stick to the minimum parameters, but if you have a newer printer, for example Anycubic cobra 3 v3, you can select the maximum recommended values

Settings for advanced users, change these parameters only if you have sufficient 3D printing expertise.