Files

3D model format

Stereolithography (.stl)

Total files

Slicer settings

not available

Mesh error check

not specified

Support

Lifetime support from Gambody team

Update requests

not specified

Model versions

DLP/SLA

Assembly method

Connectors

Features

Comes with a stand;

Contains some hollowed-out parts to save resin;

The assembly parts are connected using specially designed integrated connectors that fit securely into the corresponding slots. Optionally, for added strength and rigidity, the static assembly joints can be glued together;

FFF/FDM

Assembly method

Connectors

Features

Comes with a stand to resemble the grounds of Fangorn Forest;

The assembly parts are connected using specially designed integrated connectors that fit securely into the corresponding slots;

SLS

Assembly method

Connectors

Features

Comes with a stand;

Contains 3 parts: a solid one-piece model with the stand integrated, and an alternative Merry Brandybuck model with a separate platform;

The assembly parts are connected using specially designed integrated connectors that fit securely into the corresponding slots. Optionally, for added strength and rigidity, the static assembly joints can be glued together;

DLP/SLA

Assembly method

Connectors

Features

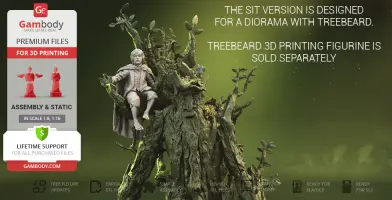

Designed for Treebeard diorama integration (Treebeard and Pippin Took 3D print models are sold separately);

Contains some hollowed out parts to save resin;

The assembly parts are connected using specially designed integrated connectors that fit securely into the corresponding slots. Optionally, for added strength and rigidity, the static assembly joints can be glued together;

FFF/FDM

Assembly method

Connectors

Features

Designed for Treebeard diorama integration (Treebeard and Pippin Took 3D print models are sold separately);

The assembly parts are connected using specially designed integrated connectors that fit securely into the corresponding slots;

SLS

Assembly method

Connectors

Features

Designed for Treebeard diorama integration (Treebeard and Pippin Took 3D print models are sold separately);

Made as a solid one-piece STL file;

The assembly parts are connected using specially designed integrated connectors that fit securely into the corresponding slots. Optionally, for added strength and rigidity, the static assembly joints can be glued together;

Additional details

Part of diorama

No

Special pack included

No

You can get the STL files of Merry Brandybuck for 3D Printing immediately after the purchase! Just click the green Buy button in the top-right corner of the model’s page. You can pay with PayPal or your credit card.

Watch the tutorial on how to assemble the 3D Printed Merry Brandybuck from the provided 3D Print Files at Gambody YouTube channel.

Also, you may like Treebeard and Pippin Took 3D Printing Models to complete the diorama, as well as other LOTR 3D Printing Designs.

_______

FAQ:

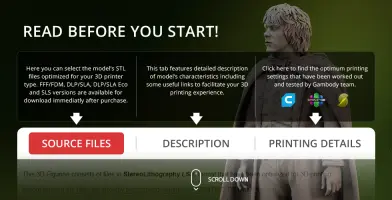

This 3D model comes with StereoLithography (.STL) files optimized for 3D printing. You'll get digital files, not a physical product

Before printing, take a look at Printing Details for recommended settings and tips to achieve better results.

Merry Brandybuck 3D Printer Files | Assembly includes 3 version(s) for the supported 3D printer type(s): FFF/FDM, DLP/SLA, SLS. Files are available for download after purchase.

See the Description and Specifications sections for more details about this model.

3D model history

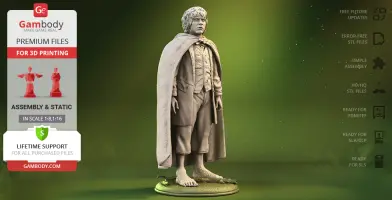

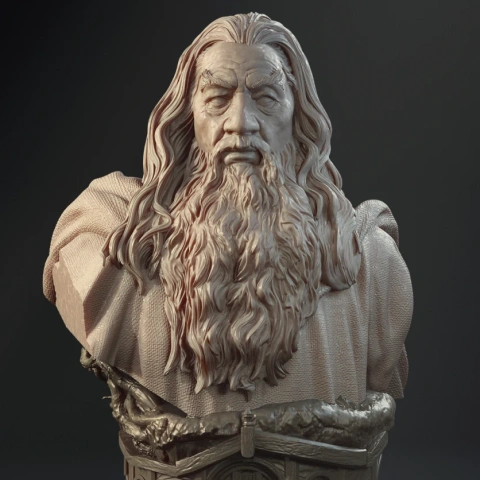

Meriadoc Brandybuck, known as Merry, is the character from the Middle-earth legendarium who participates in the Quest to destroy the One Ring, helps to defeat Witch-king of Angmar, and simply has fun together with his inseparable friend Pippin. We are delighted to welcome the cheerful and brave Master of Buckland to join our The Lord of the Ringsselection! Being a true LotR fan, the author of the 3D printer model kept his word and prepared a friendly hobbit for 3D printing to accompany Treebeard in its Last March of the Ents. Even more so!

The 3D artist behind the Merry Brandybuck model reportedly spent circa 150 hours in order for the loyal hobbit to be featured in two scenarios at the least! Thus, the Meriadoc 3D model can be displayed either standing still on a small decorative platform or sitting on top of Treebeard’s branches. The member of the Fellowship of the Ring is depicted with careful attention both to the peculiarities of hobbits’ appearance and their customary clothes. Merry model is barefooted, his longishhairstyle is naturally curly and the look on his face is rather concerned. The latter is quite understandable - after all, Merry, his dear friend Pippin and the Shepherd of the Trees are on their way to fight the Orcs of Isengard! Just like most hobbits do, Meriadoc Brandybuck 3D print wears breeches, a waistcoat, a jacket, and a cloak with a large hood. The cloak is fastened with a brooch known as the Leave of Lorien which is the distinctive symbol worn by all members of the Fellowship of the Ring. The cheerful star of the LotR trilogy is a caring and resourceful hobbit who knows everything needed about the second breakfast! We can’t think of a more joyful addition to your J.R.R. Tolkien-inspired 3D printing design collection!

3D printing model features

Model-specific features:

- Comes in both independent Stand pose with a Fangorn Forest-themed base, and a Sit pose specifically designed to integrate with the Treebeard 3D print model (sold separately);

- The Sit option's body is expertly carved to fit the texture of Treebeard's branches, ensuring harmonious assembly of the diorama;

- Model parts are thoroughly cut along the clothing seams and cape contours, effectively hiding the connection points and giving it a seamless appearance.

Printing & assembly details:

- Provided as error-free STL files compatible with most 3D printers;

- Optimized part division minimizes support material and ensures smooth surface detail;

- The assembly parts in the FFF/FDM version come in the recommended print orientations for easy bed placement;

- Assembly manual in video format is included for both FFF/FDM and DLP/SLA versions;

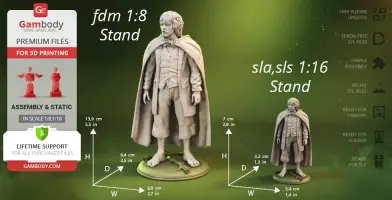

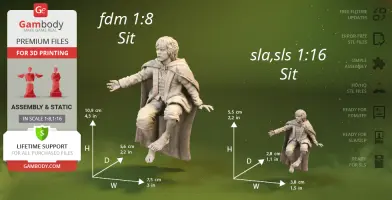

- The model is available in recommended scales of 1:8 for the FFF/FDM version and 1:16 for the DLP/SLA/SLS versions, based on the 1060 mm height of Merry Brandybuck.

What will you get after purchase?

- 6 versions of Merry Brandybuck STL files for FFF/FDM, DLP/SLA and SLS - files for each version are available for download after the purchase;

- STL files of high-poly Merry Brandybuck 3D printer model consist of 40 parts;

- Sizes:

- FFF/FDM Stand: 68 mm wide, 139 mm high, 64 mm deep;

- FFF/FDM Sit: 75 mm wide, 109 mm high, 56 mm deep;

- DLP/SLA + Eco, and SLS Stand: 34 mm wide, 70 mm high, 32 mm deep;

- DLP/SLA + Eco, and SLS Sit: 38 mm wide, 55 mm high, 28 mm deep;

- Detailed settings that we provide as a recommendation for Bambu Studio, Cura, Orca Slicer, PrusaSlicer, Simplify3D, and Slic3r for the best print;

- Full technical support from the Gambody Support Team.

Average customer rating (3 reviews)

5

Ratings breakdown

Click a star rating to filter reviews

Overall experience

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

To avoid printing issues and achieve the best quality, we highly recommend applying the following settings:

Generic

Below you can find printing recommendations for Bambu Studio, Cura, Orca Slicer, PrusaSlicer, Simplify3D, and Slic3r software.

Disclaimer: The following printing settings are a recommendation, not an obligation. The parameters can vary depending on the peculiarities of your 3D printer, the material you use, and especially the particular assembly part you are working with. Each part that any model comprises often needs preliminary review, and you are free to tweak the settings the way you find suitable.

Note:

You can scale up the model (downscaling for FFF/FDM 3D printers is not recommended!);

All connectors should be printed at 100% Infill.

Bambu Lab printing recommendations:

These basic 3D printing settings recommendations for beginners were tested in Bambu Studio 1.9.1. Test models were printed on the Bambu Lab A1, Bambu Lab A1 Mini, Creality Ender 3 S1, Anycubic Kobra 2, and Anycubic Vyper using PLA and PETG filaments.

To avoid printing problems, we recommend the following settings:download

Cura printing recommendations:

These are averaged settings which were tested in the Cura 5.2.1 slicer. Test models were printed on Anycubic Vyper, Creality Ender 3 Pro with PLA filament.

To avoid printing problems, we recommend the following settings: download

Orca Slicer printing recommendations:

These basic 3D printing settings recommendations for beginners were tested in Orca Slicer 2.3.0. Test models were printed on Bambu Lab A1, Bambu Lab A1 Mini, Creality Ender 3 V3, and Anycubic Kobra 3 with PLA and PETG filament.

To avoid printing problems, we recommend the following settings: download

PrusaSlicer printing recommendations:

These basic 3D printing settings recommendations for beginners were tested in PrusaSlicer 2.3.1. Test models were printed on Ultimaker 2, Creality Ender 3, Creality Cr-10S pro v2, Anycubic I3 Mega, Anycubic I3 MegaS, Anycubic Vyper with PLA and PETG filaments.

To avoid printing problems, we recommend the following settings:download

Simplify3D printing recommendations:

These are averaged settings which were tested in the Simplify3D 5.0.0 slicer. Test models were printed on Anycubic Vyper, FLSUN v400, Ender3 S1 with PLA filament.

To avoid printing problems, we recommend the following settings:download

Slic3r printing recommendations:

These basic 3D printing settings recommendations for beginners were tested in Slic3r 1.3.0 software. Test models were printed on Ultimaker 2, Creality Ender 3, Creality Cr-10S pro v2, Anycubic I3 Mega, Anycubic I3 MegaS, Anycubic Vyper with PLA and PetG filaments.

To avoid printing problems, we recommend the following settings:download

SLS

Designed for Treebeard diorama integration (Treebeard and Pippin Took 3D print models are sold separately);

Made as a solid one-piece STL file;

The assembly parts are connected using specially designed integrated connectors that fit securely into the corresponding slots. Optionally, for added strength and rigidity, the static assembly joints can be glued together;

SLS

Comes with a stand;

Contains 3 parts: a solid one-piece model with the stand integrated, and an alternative Merry Brandybuck model with a separate platform;

The assembly parts are connected using specially designed integrated connectors that fit securely into the corresponding slots. Optionally, for added strength and rigidity, the static assembly joints can be glued together;

DLP/SLA

Designed for Treebeard diorama integration (Treebeard and Pippin Took 3D print models are sold separately);

Contains some hollowed out parts to save resin;

The assembly parts are connected using specially designed integrated connectors that fit securely into the corresponding slots. Optionally, for added strength and rigidity, the static assembly joints can be glued together;

DLP/SLA

Comes with a stand;

Contains some hollowed-out parts to save resin;

The assembly parts are connected using specially designed integrated connectors that fit securely into the corresponding slots. Optionally, for added strength and rigidity, the static assembly joints can be glued together;

FFF/FDM

Designed for Treebeard diorama integration (Treebeard and Pippin Took 3D print models are sold separately);

The assembly parts are connected using specially designed integrated connectors that fit securely into the corresponding slots;