Files

3D model format

Stereolithography (.stl)

Total files

Slicer settings

Mesh error check

not specified

Support

Lifetime support from Gambody team

Update requests

not specified

Model versions

FFF/FDM

Assembly method

not specified

Features

DLP/SLA

Assembly method

not specified

Features

Additional details

Part of diorama

No

Special pack included

No

You will get instant access to the STL files of James Bond's Aston Martin DB5 3D Printer Files | Assembly + Action after completing your purchase. Simply add the model to your cart and check out using PayPal, credit or debit card, Apple Pay, Google Pay, Alipay, or other available payment methods.

Watch the assembly video for James Bond's Aston Martin DB5 3D Printer Files | Assembly + Action, and explore more tutorials, behind-the-scenes content, 3D printing timelapses, and painting guides on the official Gambody YouTube channel.

This 3D model of James Bond's Aston Martin DB5 consists of files in StereoLithography (.Stl) format that is optimized for 3D printing.

Before printing the files, we strongly recommend reading the PRINTING DETAILS section.

WHAT WILL YOU GET AFTER PURCHASE?

- 2 versions of James Bond's Aston Martin DB5 STL files for FFF/FDM and DLP/SLA 3D printers — files for all versions are available for download after the purchase;

- STL files of high-polyJames Bond's Aston Martin DB5 model for 3D printing consist of 302 files;

- Sizes for:

- FFF/FDM without platform: 166 mm tall, 213 mm wide, 577 mm deep;

- FFF/FDM on a platform: 196 mm tall, 345 mm wide, 600 mm deep;

- DLP/SLA without platform: 83 mm tall, 107 mm wide, 289 mm deep;

- DLP/SLA on a platform: 98 mm tall, 173 mm wide, 300 mm deep;

- Assembly Manual for 1.0 FFF/FDM and 1.0 DLP/SLA versions in PDF and video formats;

- Detailed settings that we provide as a recommendation for Cura, Bambu Studio, Simplify3D, Slic3r and PrusaSlicer for the best print;

- Full technical support from the Gambody Support Team.

Detailed information about these 3D printer files is available in the DESCRIPTION section.

Before printing, take a look at Printing Details for recommended settings and tips to achieve better results.

ABOUT THIS 3D MODEL

The Aston Martin DB5 is arguably the most iconic car in cinematic history, forever associated with the legendary James Bond. First appearing in the groundbreaking movie Goldfinger, this elegant and powerful vehicle became synonymous with 007's sophisticated style and penchant for advanced gadgets. The Aston Martin DB5 has since made numerous appearances throughout the popular film franchise, solidifying its status as the quintessential James Bond vehicle and a dream car for fans worldwide. Its timeless design and array of unforgettable features have cemented its place in popular culture, making it a must-have for any fan of classic cars and thrilling spy movies.

Our contributing artist has masterfully translated this classic design into a highly detailed Aston Martin DB5 3D model, available as STL files for avid 3D printed car enthusiasts. This Aston Martin DB5 model is packed with impressive features, including rotating wheels with extendable tire-shredding blades and fully opening hood, doors, and trunk. Fans of the Goldfinger movie will be thrilled with the deployable battering rams, revolving license plates, and the option to swap the front lights for machine guns and the rear for an oil-slick delivery system. The James Bond Aston Martin DB5 model also offers customizable window glass, a detailed interior with movable elements like sun visors and an opening glove box, an onboard radar display, and even the option for backlighting. Perfect for any fan of the James Bond vehicle legacy, this model is a standout piece in the world of cars and movie memorabilia.

ADAPTATION FOR 3D PRINTING

James Bond's Aston Martin DB5 model for 3D printing is an active assembly model and its moderation and adaptation for different types of 3D printers took the Gambody team 104 hours in total.

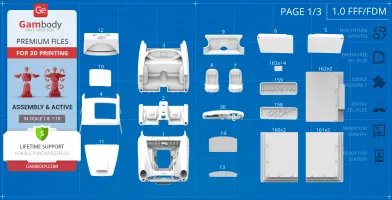

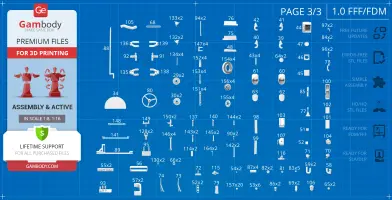

For you to receive the cleanest 3D printing result possible, minimize the amount of filament needed for generated support, and make use of the active elements designed by Gambody Engineers, the vehicle was divided into convenient assembly parts.

All assembly parts in the 1.0 FFF/FDM version are provided in STL files in recommended positions that were worked out in order to ensure the smoothness of the details’ surfaces after printing and that the 3D printing beginners won’t face difficulties when placing the parts on a build plate. When downloading any model’s file you will also receive “Assembly Manual” for 1.0 FFF/FDM and 1.0 DLP/SLA versions in PDF and video formats. We highly recommend that you get acquainted with the “Assembly Video” and “Assembly Manual” before getting down to the Aston Martin DB5 3D model.

The design is saved in STL files, a format supported by most 3D printers. All STL files for 3D printing have been checked in Netfabb and no errors were shown.

The 3D model’s scale was calculated from the length of the vehicle which is 4570 mm. The 3D printer design’s chosen scales are 1:8 for the FFF/FDM version, and 1:16 for the DLP/SLA version.

VERSIONS’ SPECIFICATIONS

FFF/FDM 1.0 version features:

- Contains 177 parts;

- A printed car model is 166 mm tall, 213 mm wide, 577 mm deep;

- A printed car on a platform is 196 mm tall, 345 mm wide, 600 mm deep;

- Rotating wheels with extendable tire-shredding blades (wheels on bearings);

- Tires with and without lettering (can be printed using TPU filament);

- The steering wheel rotates, turning the front wheels;

- Choose between static or active suspension; Static suspension uses pistons and a spring from a ballpoint pen (*two springs may be needed for sufficient elasticity);

- Authentic detailing of the engine and gearbox;

- The driveshaft can rotate (*does not drive the wheels);

- Fully opening hood, doors, and trunk;

- Deployable battering rams on the bumper;

- Revolving license plates;

- Option to print chrome inserts separately;

- Front lights can be replaced with machine guns; Rear lights can be swapped for an oil-slick delivery system;

- Customizable window glass: print with transparent filament or use custom frames (with special templates for cutting flexible transparent materials);

- Bullet-proof rear screen available in two options: lowered and raised;

- Trunk customization: install a case or use a placeholder cover; Spare tire stored under a removable cover;

- Removable trunk cover for battery access;

- Removable roof hatch for highly detailed interior access;

- Movable sun visors and an opening glove box;

- Opening compartment in the driver's door with a radio telephone;

- Onboard radar display with a removable protective cover;

- Two types of platform nameplates and an themed display platform;

- Removable trunk cover for battery access;

- Tunnels for LED wiring to illuminate the car's headlights, instrument panel, and radar (*for instrument panel and radar, it is recommended to print the dials on paper and glue them from the back);

- All parts are divided in such a way that you will print them with the smallest number of support structures.

DLP/SLA 1.0 version features:

- Contains 125 parts;

- A printed car model is 83 mm tall, 107 mm wide, 289 mm deep;

- A printed car on a platform is 98 mm tall, 173 mm wide, 300 mm deep;

- Body and suspension are merged for easier printing;

- Rotating wheels with extendable tire-shredding blades;

- Tires with and without lettering (can be printed using TPU on a filament 3D printer);

- The steering wheel rotates, turning the front wheels;

- Authentic detailing of the engine and gearbox;

- The driveshaft can rotate (*does not drive the wheels);

- Fully opening hood, doors, and trunk;

- Deployable battering rams on the bumper;

- Revolving license plates;

- Option to print chrome inserts separately;

- Front lights can be replaced with machine guns; Rear lights can be swapped for an oil-slick delivery system;

- Customizable window glass: print with transparent filament or use custom frames (with special templates for cutting flexible transparent materials);

- Bullet-proof rear screen available in two options: lowered and raised;

- Trunk customization: install a case or use a placeholder cover; Spare tire stored under a removable cover;

- Removable trunk cover for battery access;

- Removable roof hatch for highly detailed interior access;

- Movable sun visors and an opening glove box;

- Opening compartment in the driver's door with a radio telephone;

- Onboard radar display with a removable protective cover;

- Two types of platform nameplates and an themed display platform;

- Removable trunk cover for battery access;

- Tunnels for LED wiring to illuminate the car's headlights, instrument panel, and radar (*for instrument panel and radar, it is recommended to print the dials on paper and glue them from the back);

- All parts are divided in such a way that you will print them with the smallest number of support structures.

You can get the STL files of James Bond's Aston Martin DB5 for 3D printing immediately after the purchase! Just click the green Buy button in the top-right corner of the model’s page. You can pay with PayPal or your credit card.

Watch the tutorial on how to assemble the 3D printed James Bond's Aston Martin DB5 model from the provided 3D print files onGambody YouTube channel.

Also, you may like other Cars3D Printing Designs.

________

FAQ:

Average customer rating (5 reviews)

4

Ratings breakdown

Click a star rating to filter reviews

Overall experience

Level of detail in the model

4

Model cut quality and assembly guide

4

Clarity and accuracy of the model page

4

Level of detail in the model

4

Model cut quality and assembly guide

4

Clarity and accuracy of the model page

4

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

1

Model cut quality and assembly guide

1

Clarity and accuracy of the model page

1

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Below you'll find detailed slicing settings for Bambu Studio 2.0+, Orca Slicer 2.0+, UltiMaker Cura 5.0+, PrusaSlicer 2.0+, Slic3r 1.3+, Simplify3D 5.0+ to help you get the best results when printing this model. These settings are optimized specifically for this 3D model, but please note they may need slight adjustments depending on your printer or filament. When in doubt, refer to your printer's user manual.

To avoid printing issues and achieve the best quality, we highly recommend applying the following settings:

For better quality use 0.12 mm layer height, for fast printing use 0.2 mm layer height. For pins and the Ge connectors, use 0.2 layer height.

120-150% of your Layer Height

But you can paint the seam if you want.

You have to calibrate this parameter

You have to calibrate this parameter

You have to calibrate this parameter

For pins and power elements of the structure, such as the vehicle frame, use 3 loop

Disabled for vehicles and enabled for characters

For 0,2 Layer Height

The parameters in this tab vary greatly, it all depends on the quality of your printer. For example, if you have a classic Ender3, stick to the minimum parameters, but if you have a newer printer, for example Anycubic cobra 3 v2, you can select the maximum recommended values

Settings for advanced users, change these parameters only if you have sufficient 3D printing expertise

Enable this parameter if your model requires supports

We also recommend placing and removing supports manually in some places using special button

1-2 loops for more thick support

Top Z distance = 1-1.3 layer Height. If the supports are hard to remove, try increasing this setting by 0.1-0,4 mm

Bottom Z distance = 1-1.3 layer Height. If the supports are hard to remove, try increasing this setting by 0.1-0,4 mm

You have to calibrate this parameter which one is better for your filament

Increase this parameter if the supports are hard to remove from walls

For PLA and PETG filament types

5-8 mm is optional for small prints that have bad adhesion to the build plate

You have to calibrate this parameter

Read the description on your filament roll

Read the description on your filament roll and increase this parameter for fast printers

Read the description on your filament roll and increase this parameter for fast printers

For better quality use 0.12 mm layer height, for fast printing use 0.2 mm layer height. For pins and the Ge connectors, use 0.2 layer height.

120-150% of your Layer Height

But you can paint the seam if you want.

0.01-0.05 You have to calibrate this parameter

0.01-0.05 You have to calibrate this parameter

0.1-0.2 You have to calibrate this parameter

For pins and power elements of the structure, such as the vehicle frame, use 3 loop

Disabled for vehicles and ships, enabled for characters

For 0,2 Layer Height

For 0,2 Layer Height

The parameters in this tab vary greatly, it all depends on the quality of your printer. For example, if you have a classic Ender3, stick to the minimum parameters, but if you have a newer printer, for example, Anycubic Kobra 3 Or Bambulab A1, you can select the maximum recommended values.

Settings for advanced users, change these parameters only if you have sufficient 3D printing expertise

Enable this parameter if your model requires supports

We also recommend placing and removing supports manually in some places using special button

Top Z distance = 1-1.3 layer Height. If the supports are hard to remove, try increasing this setting by 0.1-0,4 mm

Bottom Z distance = 1-1.3 layer Height. If the supports are hard to remove, try increasing this setting by 0.1-0,4 mm

Increase this parameter if the supports are hard to remove from walls

For PLA and PETG filament types

5-8 mm is optional for small prints that have bad adhesion to the build plate

Read the description on your filament roll

Read the description on your filament roll and increase this parameter for fast printers

You have to calibrate this parameter

Read the description on your filament roll and increase this parameter for fast printers

Read the description on your filament roll

This field is filled in according to your printer specifications when you add it to the slicer.

You can add custom G-code here for the start and end of the print. However, be careful - this is for advanced users only!

You have to calibrate your printer using Ge retraction test models

Retraction Length: For direct-drive setups use 0.5 mm to 2.5 mm; for Bowden extruders use 5 to 7 mm

This is how fast the filament is pulled back—40-60 mm/s for direct drive and 30-50 mm/s for Bowden setups.

You have to calibrate this parameter: Reduce it until the printer starts to hit the parts with the nozzle during printing, then increase it by 0.2.

For better quality use 0.12 mm layer height, for fast printing use 0.2 mm layer height. For pins and the Ge connectors, use 0.2 layer height.

120-150% of your Layer Height

To increase the strength of the print parts, use wall line count: 3

For pins and connectors use 50% Infill

These parameters are for standard PLA plastic. If you are using a different type of plastic, check the printing temperature recommended by the manufacturer. Also, read the description on your filament spool. For fast printers, add +30 °C to the current parameters.

The parameters in this tab vary greatly, it all depends on the quality of your printer. For example, if you have a classic Ender3, stick to the minimum parameters, but if you have a newer printer, for example Anycubic cobra 3 v3, you can select the maximum recommended values

Settings for advanced users, change these parameters only if you have sufficient 3D printing expertise.

You need to calibrate this parameter using Gambody test models. These values are average values for a Direct Drive extruder; for a Bowden extruder, the values should be increased.

You need to calibrate this parameter using Gambody test models. These values are average values for a Direct Drive extruder; for a Bowden extruder, the values should be increased.

Use this value other than 0 if your nozzle catches on the internal infill during travel moves. Try to keep this value as low as possible in height.

Use normal supports to support large, straight surfaces (most mechanical or technical parts).

You have to calibrate this parameter according to the capabilities of your printer and your filament, using a Gambody test models.

Use 1 instead of 0 if your supports are thin and tall. They will be harder to remove, but much stronger.

Top Z distance = 1-1.3 layer Height. If the supports are hard to remove, try increasing this setting by 0.1-0,4 mm

Increase this parameter if the supports are hard to remove from walls

Use tree supports to support complex objects, such as characters.

You have to calibrate this parameter according to the capabilities of your printer and your filament, using a Gambody test models.

Top Z distance = 1-1.3 layer Height. If the supports are hard to remove, try increasing this setting by 0.1-0,4 mm

Increase this parameter if the supports are hard to remove from walls

Use a skirt for all parts when printing on outdated printers.

Use a brim when printing thin but tall parts, as well as parts with a small bed adhesion area.

For better quality use 0.12 mm layer height, for fast printing use 0.2 mm layer height. For pins and the Ge connectors, use 0.2 layer height.

120-150% of your Layer Height

for 0.2 Layer Height

But you can paint the seam if you want.

(for PLA and PETG)

(5-8 mm is optional for small prints that have bad adhesion to the build plate)

Enable this parameter if your model requires supports

(45-50 degree)You have to calibrate this parameter according to the capabilities of your printer

and your filament, using a Gambody test models.

Top contact Z distance = 1-1.3 layer Height. If the supports are hard to remove, try

increasing this setting by 0.1-0,4 mm

Top contact Z distance = 1-1.3 layer Height. If the supports are hard to remove, try

increasing this setting by 0.1-0,4 mm

Increase this parameter if the supports are hard to remove from walls

The parameters in this tab vary greatly, it all depends on the quality of your printer. For example, if you have a classic Ender3, stick to the minimum parameters, but if you have a newer printer, for example Anycubic cobra 3 v3, you can select the maximum recommended values

Settings for advanced users, change these parameters only if you have sufficient 3D printing expertise. Use the minimum value for outdated printers without acceleration calibration, and the maximum value for modern printers if you need it.

These settings only work for 3D printers with multiple extruders

You can try setting all parameters in this section, except the First layer, to values between 0.75% of your nozzle diameter and 1.25% of your nozzle diameter. Adjusting them will help you work out the optimal parameters for the best quality for your print. As for the First layer, you can set it to 150% of the diameter of your nozzle for better adhesion to the build plate (for a nozzle with a diameter of 0.4 mm, the First layer extrusion width can be from 0.3 mm to 0.5 mm)

For better printing quality you have to calibrate this parameter using Gambody test model.

Check your filament manufacturer's temperature recommendations on the spool.

Cooling parameters depends on the material you use for printing.

*for PLA

For better quality use 0.12 mm layer height, for fast printing use 0.2 mm layer height. For pins and the Ge connectors, use 0.2 layer height.

120-150% of your Layer Height

For 0.12 Layer Height

For 0.12 Layer Height

For pins and connectors use 50% Infill

Use skirt for outdated 3d printers

(5-8 mm is optional for small prints that have bad adhesion to the build plate)

Enable this parameter if your model requires supports

(45-60 degree)You have to calibrate this parameter according to the capabilities of your printer and your filament, using a Gambody test models

Contact Z distance = 1-1.3 layer Height. If the supports are hard to remove, try increasing this setting by 0.1-0,4 mm

The parameters in this tab vary greatly, it all depends on the quality of your printer. For example, if you have a classic Ender3, stick to the minimum parameters, but if you have a newer printer, for example Anycubic cobra 3 v3, you can select the maximum recommended values

Settings for advanced users, change these parameters only if you have sufficient 3D printing expertise. Use the minimum value for outdated printers without acceleration calibration, and the maximum value for modern printers if you need it.

You have to calibrate this parameter from 0.9 to 1.1 according to the capabilities of your printer and your filament, using a Gambody test models.

Check your filament manufacturer's temperature recommendations on the spool.

Cooling parameters depends on the material you use for printing.

Calibrate this value if you need to reduce or improve the adhesion between the plastic and the heat bed

Your current nozzle diameter

You need to calibrate this parameter using Gambody test models. These values are average values for a Direct Drive extruder; for a Bowden extruder, the values should be increased.

Your current nozzle diameter

You have to calibrate this parameter using Gambody test models.

You need to calibrate this parameter using Gambody test models. These values are average values for a Direct Drive extruder; for a Bowden extruder, the values should be increased.

For better quality use 0.12 mm layer height, for fast printing use 0.2 mm layer height. For pins and the Ge connectors, use 0.2 layer height.

For 0,2 Layer Height

For 0,2 Layer Height

To increase the strength of the print parts, use Outline Perimeters: 3

You can enable this parameter to print rounded or spherical models, as well as character models.

Use this option only if your parts are too tight. but better calibrate your printer extrusion

Use this option only if your parts are too tight. but better calibrate your printer extrusion

Use 2 and more if you want to create skirt instead brim

1-2 for skirt and 10-20 for brim

Use for wipe nozzle if you need

Use For ABS filament

For pins and connectors use 50% Infill

Top Z distance = 1-1.3 layer Height. If the supports are hard to remove, try increasing this setting by 0.1-0,4 mm

Calibrate your filament and detect optimal temperature for it

Average temperature for PLA filament

The parameters in this tab vary greatly, it all depends on the quality of your printer. For example, if you have a classic Ender3, stick to the minimum parameters, but if you have a newer printer, for example Anycubic cobra 3 v3, you can select the maximum recommended values

Settings for advanced users, change these parameters only if you have sufficient 3D printing expertise.