Files

3D model format

Stereolithography (.stl)

Total files

Slicer settings

Mesh error check

not specified

Support

Lifetime support from Gambody team

Update requests

not specified

Model versions

FFF/FDM

Assembly method

not specified

Features

DLP/SLA

Assembly method

not specified

Features

FFF/FDM

Assembly method

not specified

Features

FFF/FDM

Assembly method

not specified

Features

DLP/SLA

Assembly method

not specified

Features

Additional details

Part of diorama

No

Special pack included

No

You will get instant access to the STL files of BT-7274 Titanfall 3D Printer Files | Assembly + Action after completing your purchase. Simply add the model to your cart and check out using PayPal, credit or debit card, Apple Pay, Google Pay, Alipay, or other available payment methods.

Watch the assembly video for BT-7274 Titanfall 3D Printer Files | Assembly + Action, and explore more tutorials, behind-the-scenes content, 3D printing timelapses, and painting guides on the official Gambody YouTube channel.

This 3D printing design of BT-7274 3D model from the Titanfall 2 video gameconsists of files in StereoLithography (.Stl) format that is optimized for 3D printing.

Before printing the files, we strongly recommend reading the PRINTING DETAILS section.

WHAT WILL YOU GET AFTER PURCHASE?

- 5 versions of BT-7274 Titanfall STL files for FFF/FDM and DLP/SLA— files for all versions are available for download after the purchase;

- STL files of high-poly BT-7274 Titanfall model for 3D printing consist of 523 files;

- Sizes for:

- FFF/FDM: 415 mm tall, 329 mm wide, 359 mm deep;

- DLP/SLA: 208 mm tall, 164 mm wide, 180 mm deep;

- Assembly Manual for FFF/FDM 2.0 and DLP/SLA 2.0 versions in PDF and video formats;

- Detailed settings that we provide as a recommendation for Cura, Bambu Studio, Simplify3D, Slic3r and PrusaSlicer for the best print;

- Full technical support from the Gambody Support Team.

Detailed information about these 3D printer STL files is available in the DESCRIPTION section.

Before printing, take a look at Printing Details for recommended settings and tips to achieve better results.

ABOUT THIS 3D MODEL

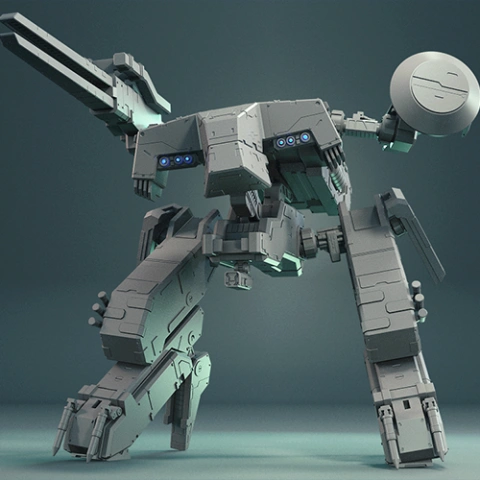

From the action-packed video games of Titanfall emerges BT-7274, the iconic Vanguard-class Titan and central character of Titanfall 2. More than just a machine, BT-7274, often referred to simply as BT, captivated players with its distinct personality, AI-driven dialogue, and unwavering loyalty to its pilot, Jack Cooper. Bound by the three protocols—Link to Pilot, Uphold the Mission, and Protect the Pilot—BT transcends the role of a mere combat vehicle, demonstrating independent thought and a deep connection to its human counterpart in the war-torn future of the Frontier. This extraordinary bond between Titan and the pilot has made Titanfall BT-7274 a fan-favorite figure within the gaming community.

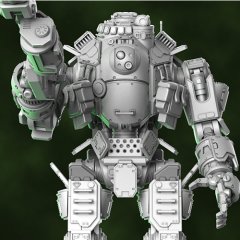

Showcase the legendary BT-7274 Titanfall in all its glory with this meticulously designed Titanfall 3D model. Featuring highly articulated joints, this model offers versatile posing options, letting you recreate BT's combat stances with precision. The articulated missile pods on its back add to its formidable appearance, while the opening cockpit provides a space for the pilot figure (available separately in the Titanfall Militia Pilot and Weapons Pack) Whether displayed on its themed platform or posed for battle, this 3D printing design is a prime addition to any collection celebrating the Titanfall universe.

ADAPTATION FOR 3D PRINTING

BT-7274 3D printing design is a highly articulated action assembly model and its moderation and adaptation for different types of 3D printers took Gambody team 62 hours in total. In order to ensure the Titan's multidirectional movement, it was divided into many assembly parts and special mechanisms were introduced into all model's joints to give you an opportunity to display BT in a variety of positions, i.e. robot's shoulders, elbows, wrists, knees, feet, every single finger's phalange, BT's eye etc. are movable and the missile pods on the mode's shoulders are fully extendable.

All assembly parts in the FFF/FDM versions are provided in STL files in recommended positions that were worked out in order to ensure the smoothness of the details’ surfaces after printing and that the 3D printing beginners won’t face difficulties when placing the parts on a build plate. When downloading any model’s file you will also receive "Assembly Manual" for 2.0 FFF/FDM and 2.0 DLP/SLA versions in PDF and video formats. We highly recommend that you get acquainted with the "Assembly Video" and "Assembly Manual" before getting down to the BT-7274.

The design is saved in STL files, a format supported by most 3D printers. All STL files for 3D printing have been checked in Netfabb and no errors were shown.

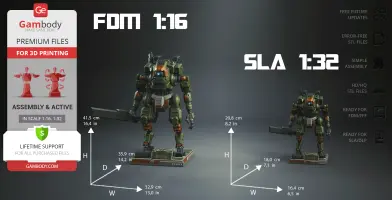

The 3D model's scale was calculated from the BT-7274's height, which is 6200 mm. The 3D printer design's chosen scales are 1:16 for the FFF/FDM version and 1:32 for the DLP/SLA version.

VERSIONS' SPECIFICATIONS

2.0 FFF/FDM version's features:

- Contains 108 parts;

- A printed model is 415 mm tall, 329 mm wide, 329 mm deep;

- Fully updated version with reworked joints and enhanced level of detail;

- The pilot's cockpit is accessible from the front and top;

- Two cockpit lamp options;

- Rotating torso;

- Articulated Titan's "eye";

- Articulated arm joints, including shoulders, elbows, wrists, and fingers;

- Movable hips and knees, as well as articulated lower legs and feet;

- Equipped with articulated read missile pods and optional weapon mount or placeholder cover;

- LED lighting tunnels for engines, cockpit, and headlights, plus a removable battery access cover;

- Comes with the platform that can accommodate a weapon case or a Pilot figure (sold separately);

- All parts are divided in such a way that you will print them with the smallest number of support structures.

2.0 DLP/SLA version's features:

- Contains 60 parts;

- A printed model is 208 mm tall, 164 mm wide, 180 mm deep;

- Fully updated version with reworked joints and enhanced level of detail;

- The pilot's cockpit is accessible from the from and top;

- Rotating torso;

- Articulated Titan's "eye";

- Articulated arm joints, including shoulders, elbows, wrists, and fingers;

- Movable hips and knees, as well as articulated lower legs and feet;

- Equipped with articulated read missile pods and optional weapon mount or placeholder cover;

- LED lighting tunnels for engines, cockpit, and headlights, plus a removable battery access cover;

- Comes with the platform that can accommodate a weapon case or a Pilot figure (sold separately);

- All parts are divided in such a way that you will print them with the smallest number of support structures.

1.1 FFF/FDM version's features:

- Contains 150 parts;

- A printed model is 378 mm tall, 204 mm wide, 164 mm deep;

- An updated version with improved connectors and joints that ensure articulation;

- Has new ratchet mechanism joints in shins, hips, waist (on each side), and elbows;

- Comes with an updated secure wrist fixation;

- Further specifications from the model's 1.0 FFF/FDM version are preserved in this version;

- All parts are divided in such a way that you will print them with the smallest number of support structures and to ensure the smoothness of the details' surfaces;

1.0 FFF/FDM version's features:

- Contains 128 parts;

- A printed model is 378 mm tall, 204 mm wide, 164 mm deep;

- Assembly kit includes locks to connect the parts without glue. One lock 124_Ge_lock_10H_x37 needs to be printed 37 times;

- Wires 28_pelvis_pipe_flexible_R_FDM and 31_pelvis_pipe_flexible_L_FDM that are to be inserted into the robot's pelvis are recommended to be printed with flexible filament to preserve leg's articulation; camera part 36_cam_for_stl_no_support_FDM is to be printed without supports (support parameter should be disable in your slicer);

- Made with several sets of special joints to ensure full articulation of the model's limbs and body;

- The front part of Titan can be fully opened for you to access highly-detailed cockpit;

- Made with opening hatches, fully extendable and spinning missile pods and movable eye socket;

- Titan is equipped with its primary XO16A2 Chaingun weapon;

- All parts are divided in such a way that you will print them with the smallest number of support structures and to ensure the smoothness of the details' surfaces;

1.0 DLP/SLA version's features:

- Contains 77 parts;

- A printed model is 189 mm tall, 102 mm wide, 82 mm deep;

- Made with several sets of special joints to ensure full articulation of the model's limbs and body;

- The front part of Titan can be fully opened for you to access highly-detailed cockpit;

- Made with opening hatches, fully extendable and spinning missile pods and movable eye socket;

- Titan is equipped with its primary XO16A2 Chaingun weapon;

- All parts are divided in such a way that you will print them with the smallest number of support structures and to ensure the smoothness of the details' surfaces;

You can get the STL files of BT-7274 3D print model immediately after the purchase! Just click the green Buy button in the top-right corner of the model’s page. You can pay with PayPal or your credit card.

Watch the tutorial on how to assemble the 3D printed BT-7274 model from the provided 3D print files on Gambody YouTube channel.

Also, you may like the Atlas Titan3D Print Model as well as other Robot3D printing designs.

________

FAQ:

Average customer rating (30 reviews)

4.1

Ratings breakdown

Click a star rating to filter reviews

Overall experience

Level of detail in the model

4.1

Model cut quality and assembly guide

4

Clarity and accuracy of the model page

4.1

Level of detail in the model

5

Model cut quality and assembly guide

1

Clarity and accuracy of the model page

3

Second, the assembly manual for the FDM 2.0 version lists a part 108 in step 45, but the parts only go to 107.

https://www.gambody.com/premium/bt-7274-titanfall#source-files.

We recommend redownloading the entire FFF/FDM 2.0 Fully upgraded folder to ensure you have the latest updated version.

Please don’t hesitate to let us know if you need further assistance with your Titanfall 3D print— we’re always happy to help!

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

2

Model cut quality and assembly guide

2

Clarity and accuracy of the model page

2

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

3

Model cut quality and assembly guide

3

Clarity and accuracy of the model page

3

Level of detail in the model

1

Model cut quality and assembly guide

1

Clarity and accuracy of the model page

1

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

1

Model cut quality and assembly guide

1

Clarity and accuracy of the model page

1

Level of detail in the model

4

Model cut quality and assembly guide

4

Clarity and accuracy of the model page

4

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

3

Model cut quality and assembly guide

3

Clarity and accuracy of the model page

3

Level of detail in the model

1

Model cut quality and assembly guide

1

Clarity and accuracy of the model page

1

Below you'll find detailed slicing settings for Bambu Studio 2.0+, Orca Slicer 2.0+, UltiMaker Cura 5.0+, PrusaSlicer 2.0+, Slic3r 1.3+, Simplify3D 5.0+ to help you get the best results when printing this model. These settings are optimized specifically for this 3D model, but please note they may need slight adjustments depending on your printer or filament. When in doubt, refer to your printer's user manual.

To avoid printing issues and achieve the best quality, we highly recommend applying the following settings:

For better quality use 0.12 mm layer height, for fast printing use 0.2 mm layer height. For pins and the Ge connectors, use 0.2 layer height.

120-150% of your Layer Height

But you can paint the seam if you want.

You have to calibrate this parameter

You have to calibrate this parameter

You have to calibrate this parameter

For pins and power elements of the structure, such as the vehicle frame, use 3 loop

Disabled for vehicles and enabled for characters

For 0,2 Layer Height

The parameters in this tab vary greatly, it all depends on the quality of your printer. For example, if you have a classic Ender3, stick to the minimum parameters, but if you have a newer printer, for example Anycubic cobra 3 v2, you can select the maximum recommended values

Settings for advanced users, change these parameters only if you have sufficient 3D printing expertise

Enable this parameter if your model requires supports

We also recommend placing and removing supports manually in some places using special button

1-2 loops for more thick support

Top Z distance = 1-1.3 layer Height. If the supports are hard to remove, try increasing this setting by 0.1-0,4 mm

Bottom Z distance = 1-1.3 layer Height. If the supports are hard to remove, try increasing this setting by 0.1-0,4 mm

You have to calibrate this parameter which one is better for your filament

Increase this parameter if the supports are hard to remove from walls

For PLA and PETG filament types

5-8 mm is optional for small prints that have bad adhesion to the build plate

You have to calibrate this parameter

Read the description on your filament roll

Read the description on your filament roll and increase this parameter for fast printers

Read the description on your filament roll and increase this parameter for fast printers

For better quality use 0.12 mm layer height, for fast printing use 0.2 mm layer height. For pins and the Ge connectors, use 0.2 layer height.

120-150% of your Layer Height

But you can paint the seam if you want.

0.01-0.05 You have to calibrate this parameter

0.01-0.05 You have to calibrate this parameter

0.1-0.2 You have to calibrate this parameter

For pins and power elements of the structure, such as the vehicle frame, use 3 loop

Disabled for vehicles and ships, enabled for characters

For 0,2 Layer Height

For 0,2 Layer Height

The parameters in this tab vary greatly, it all depends on the quality of your printer. For example, if you have a classic Ender3, stick to the minimum parameters, but if you have a newer printer, for example, Anycubic Kobra 3 Or Bambulab A1, you can select the maximum recommended values.

Settings for advanced users, change these parameters only if you have sufficient 3D printing expertise

Enable this parameter if your model requires supports

We also recommend placing and removing supports manually in some places using special button

Top Z distance = 1-1.3 layer Height. If the supports are hard to remove, try increasing this setting by 0.1-0,4 mm

Bottom Z distance = 1-1.3 layer Height. If the supports are hard to remove, try increasing this setting by 0.1-0,4 mm

Increase this parameter if the supports are hard to remove from walls

For PLA and PETG filament types

5-8 mm is optional for small prints that have bad adhesion to the build plate

Read the description on your filament roll

Read the description on your filament roll and increase this parameter for fast printers

You have to calibrate this parameter

Read the description on your filament roll and increase this parameter for fast printers

Read the description on your filament roll

This field is filled in according to your printer specifications when you add it to the slicer.

You can add custom G-code here for the start and end of the print. However, be careful - this is for advanced users only!

You have to calibrate your printer using Ge retraction test models

Retraction Length: For direct-drive setups use 0.5 mm to 2.5 mm; for Bowden extruders use 5 to 7 mm

This is how fast the filament is pulled back—40-60 mm/s for direct drive and 30-50 mm/s for Bowden setups.

You have to calibrate this parameter: Reduce it until the printer starts to hit the parts with the nozzle during printing, then increase it by 0.2.

For better quality use 0.12 mm layer height, for fast printing use 0.2 mm layer height. For pins and the Ge connectors, use 0.2 layer height.

120-150% of your Layer Height

To increase the strength of the print parts, use wall line count: 3

For pins and connectors use 50% Infill

These parameters are for standard PLA plastic. If you are using a different type of plastic, check the printing temperature recommended by the manufacturer. Also, read the description on your filament spool. For fast printers, add +30 °C to the current parameters.

The parameters in this tab vary greatly, it all depends on the quality of your printer. For example, if you have a classic Ender3, stick to the minimum parameters, but if you have a newer printer, for example Anycubic cobra 3 v3, you can select the maximum recommended values

Settings for advanced users, change these parameters only if you have sufficient 3D printing expertise.

You need to calibrate this parameter using Gambody test models. These values are average values for a Direct Drive extruder; for a Bowden extruder, the values should be increased.

You need to calibrate this parameter using Gambody test models. These values are average values for a Direct Drive extruder; for a Bowden extruder, the values should be increased.

Use this value other than 0 if your nozzle catches on the internal infill during travel moves. Try to keep this value as low as possible in height.

Use normal supports to support large, straight surfaces (most mechanical or technical parts).

You have to calibrate this parameter according to the capabilities of your printer and your filament, using a Gambody test models.

Use 1 instead of 0 if your supports are thin and tall. They will be harder to remove, but much stronger.

Top Z distance = 1-1.3 layer Height. If the supports are hard to remove, try increasing this setting by 0.1-0,4 mm

Increase this parameter if the supports are hard to remove from walls

Use tree supports to support complex objects, such as characters.

You have to calibrate this parameter according to the capabilities of your printer and your filament, using a Gambody test models.

Top Z distance = 1-1.3 layer Height. If the supports are hard to remove, try increasing this setting by 0.1-0,4 mm

Increase this parameter if the supports are hard to remove from walls

Use a skirt for all parts when printing on outdated printers.

Use a brim when printing thin but tall parts, as well as parts with a small bed adhesion area.

For better quality use 0.12 mm layer height, for fast printing use 0.2 mm layer height. For pins and the Ge connectors, use 0.2 layer height.

120-150% of your Layer Height

for 0.2 Layer Height

But you can paint the seam if you want.

(for PLA and PETG)

(5-8 mm is optional for small prints that have bad adhesion to the build plate)

Enable this parameter if your model requires supports

(45-50 degree)You have to calibrate this parameter according to the capabilities of your printer

and your filament, using a Gambody test models.

Top contact Z distance = 1-1.3 layer Height. If the supports are hard to remove, try

increasing this setting by 0.1-0,4 mm

Top contact Z distance = 1-1.3 layer Height. If the supports are hard to remove, try

increasing this setting by 0.1-0,4 mm

Increase this parameter if the supports are hard to remove from walls

The parameters in this tab vary greatly, it all depends on the quality of your printer. For example, if you have a classic Ender3, stick to the minimum parameters, but if you have a newer printer, for example Anycubic cobra 3 v3, you can select the maximum recommended values

Settings for advanced users, change these parameters only if you have sufficient 3D printing expertise. Use the minimum value for outdated printers without acceleration calibration, and the maximum value for modern printers if you need it.

These settings only work for 3D printers with multiple extruders

You can try setting all parameters in this section, except the First layer, to values between 0.75% of your nozzle diameter and 1.25% of your nozzle diameter. Adjusting them will help you work out the optimal parameters for the best quality for your print. As for the First layer, you can set it to 150% of the diameter of your nozzle for better adhesion to the build plate (for a nozzle with a diameter of 0.4 mm, the First layer extrusion width can be from 0.3 mm to 0.5 mm)

For better printing quality you have to calibrate this parameter using Gambody test model.

Check your filament manufacturer's temperature recommendations on the spool.

Cooling parameters depends on the material you use for printing.

*for PLA

For better quality use 0.12 mm layer height, for fast printing use 0.2 mm layer height. For pins and the Ge connectors, use 0.2 layer height.

120-150% of your Layer Height

For 0.12 Layer Height

For 0.12 Layer Height

For pins and connectors use 50% Infill

Use skirt for outdated 3d printers

(5-8 mm is optional for small prints that have bad adhesion to the build plate)

Enable this parameter if your model requires supports

(45-60 degree)You have to calibrate this parameter according to the capabilities of your printer and your filament, using a Gambody test models

Contact Z distance = 1-1.3 layer Height. If the supports are hard to remove, try increasing this setting by 0.1-0,4 mm

The parameters in this tab vary greatly, it all depends on the quality of your printer. For example, if you have a classic Ender3, stick to the minimum parameters, but if you have a newer printer, for example Anycubic cobra 3 v3, you can select the maximum recommended values

Settings for advanced users, change these parameters only if you have sufficient 3D printing expertise. Use the minimum value for outdated printers without acceleration calibration, and the maximum value for modern printers if you need it.

You have to calibrate this parameter from 0.9 to 1.1 according to the capabilities of your printer and your filament, using a Gambody test models.

Check your filament manufacturer's temperature recommendations on the spool.

Cooling parameters depends on the material you use for printing.

Calibrate this value if you need to reduce or improve the adhesion between the plastic and the heat bed

Your current nozzle diameter

You need to calibrate this parameter using Gambody test models. These values are average values for a Direct Drive extruder; for a Bowden extruder, the values should be increased.

Your current nozzle diameter

You have to calibrate this parameter using Gambody test models.

You need to calibrate this parameter using Gambody test models. These values are average values for a Direct Drive extruder; for a Bowden extruder, the values should be increased.

For better quality use 0.12 mm layer height, for fast printing use 0.2 mm layer height. For pins and the Ge connectors, use 0.2 layer height.

For 0,2 Layer Height

For 0,2 Layer Height

To increase the strength of the print parts, use Outline Perimeters: 3

You can enable this parameter to print rounded or spherical models, as well as character models.

Use this option only if your parts are too tight. but better calibrate your printer extrusion

Use this option only if your parts are too tight. but better calibrate your printer extrusion

Use 2 and more if you want to create skirt instead brim

1-2 for skirt and 10-20 for brim

Use for wipe nozzle if you need

Use For ABS filament

For pins and connectors use 50% Infill

Top Z distance = 1-1.3 layer Height. If the supports are hard to remove, try increasing this setting by 0.1-0,4 mm

Calibrate your filament and detect optimal temperature for it

Average temperature for PLA filament

The parameters in this tab vary greatly, it all depends on the quality of your printer. For example, if you have a classic Ender3, stick to the minimum parameters, but if you have a newer printer, for example Anycubic cobra 3 v3, you can select the maximum recommended values

Settings for advanced users, change these parameters only if you have sufficient 3D printing expertise.