Files

3D model format

Stereolithography (.stl)

Total files

Slicer settings

not available

Mesh error check

not specified

Support

Lifetime support from Gambody team

Update requests

not specified

Model versions

FFF/FDM

Assembly method

not specified

Features

DLP/SLA

Assembly method

not specified

Features

FFF/FDM

Assembly method

not specified

Features

DLP/SLA

Assembly method

not specified

Features

Additional details

Part of diorama

No

Special pack included

No

You will get instant access to the STL files of USS Discovery NCC-1031 3D Printing Model | Assembly after completing your purchase. Simply add the model to your cart and check out using PayPal, credit or debit card, Apple Pay, Google Pay, Alipay, or other available payment methods.

Watch the assembly video for USS Discovery NCC-1031 3D Printing Model | Assembly, and explore more tutorials, behind-the-scenes content, 3D printing timelapses, and painting guides on the official Gambody YouTube channel.

This 3D Model of USS Discovery NCC-1031 consists of files in StereoLithography (.Stl) format that is optimized for 3D printing.

Before printing the files, we strongly recommend reading the PRINTING DETAILS section.

WHAT WILL YOU GET AFTER PURCHASE?

- 4 versions of USS Discovery STL files for FFF/FDM and DLP/SLA/SLS - files for all versions are available for download after the purchase

- STL files of high-poly Star Trek USS Discovery ship 3D Model for 3D printing consist of 88 parts

- Sizes:

FFF/FDM: 127 mm tall, 218 mm wide, 535 mm deep

DLP/SLA/SLS: 64 mm tall, 109 mm wide, 267 mm deep

- Assembly Manual for FFF/FDM 1.0 and DLP/SLA/SLS 1.0 versions in PDF format

- Detailed settings that we provide as a recommendation for Cura, Simplify3D and Slic3r for the best print

- Full technical support from the Gambody Support Team

Detailed information about this 3D printing model is available in the DESCRIPTION section.

Before printing, take a look at Printing Details for recommended settings and tips to achieve better results.

ABOUT THIS 3D MODEL

As it befits all Crossfield-class starships of the Federation Starfleet, USS Discovery was initially designated as a science vessel. However, following the outbreak of the Federation-Klingon War, the namesake ship of the Star Trek: Discovery series was re-classified as a warship under the command of Captain Gabriel Lorca. Distinguished by the experimental “spore” propulsion drive, the beautiful Discovery is able to jump from realm to realm and once even time-jumped 1000 years into the future!

Today, the Crossfield-class vessel from one of the most popular sci-fi television shows of all time joins Gambody’s catalogue of 3D printing starships! The USS Discovery model for 3D printing features a highly detailed saucer section that comprises three thin rings with elaborate patterns. The author of the model paid careful attention to the peculiarities of the starship’s construction in order to ensure the sophisticated design of the 3D printing saucer, secondary hull and the nacelles of the Discovery.

ADAPTATION FOR 3D PRINTING

USS Discovery for 3D printing is a static assembly model and its moderation and adaptation for different types of 3D printers took Gambody team 37 hours in total. The model’s cutting into assembly parts was made in such a way for you to receive the cleanest 3D printing result possible, to minimize the amount of filament needed for generated support and to ensure the seamless assembly of the spacecraft model.

All assembly parts are provided in STL files of the FFF/FDM version in recommended positions that were worked out to ensure the smoothness of the details’ surfaces after printing and that the 3D printing beginners won't face difficulties when placing the parts on a build plate. When downloading any model's file you will also receive "Assembly Manual" for FFF/FDM 1.0 and DLP/SLA/SLS 1.0 versions in PDF format. We highly recommend that you get acquainted with the “Assembly video” and "Assembly Manual" before getting down to the USS Discovery model.

The model is saved in STL files, a format supported by most 3D printers. All STL files for 3D printing have been checked in Netfabb and no errors were shown.

The model’s scale was calculated from the length of the original USS Discovery which is 750000 mm. The 3D printing model’s chosen scale is 1:1400 for the FFF/FDM version and 1:2800 for the DLP/SLA/SLS version.

VERSIONS' SPECIFICATIONS

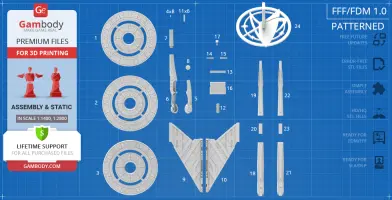

FFF/FDM Smooth 1.0 + FFF/FDM Patterned 1.0 versions feature:

- Each version contains 24 parts;

- Both printed versions stand 127 mm tall, 218 mm wide, 535 mm deep;

- As prompt the titles, two versions differ in the level of detail on the ship's saucer;

- There are two variants of the upper hull - with or without ship’s name USS Discovery (NCC-1031);

- You can mount the ship on a special platform with Star Trek logo or conceal the designated slot with a cap;

- There are tunnels inside the ship for you to introduce LED wiring and light up the heart of the saucer and the nacelles; a spot to hide the battery is provided inside the secondary hull;

- All parts are divided in such a way that you will print them with the smallest number of support structures.

DLP/SLA/SLS Smooth 1.0 + DLP/SLA/SLS Patterned 1.0 versions feature:

- Each version contains 20 parts;

- Both printed versions stand 64 mm tall, 109 mm wide, 267 mm deep;

- As prompt the titles, two versions differ in the level of detail on the ship's saucer;

- There are two variants of the upper hull - with or without ship’s name USS Discovery (NCC-1031);

- You can mount the ship on a special platform with Star Trek logo or conceal the designated slot with a cap;

- There are tunnels inside the ship for you to introduce LED wiring and light up the heart of the saucer and the nacelles; a spot to hide the battery is provided inside the secondary hull;

- All parts are divided in such a way to fit the build plates and to ensure that support structures are generated where needed.

You can get the model of USS Discovery NCC-1031 for 3D Printing immediately after the purchase! Just click the green Buy button in the top-right corner of the model’s page. You can pay with PayPal or your credit card.

Watch the tutorial on how to assemble the USS Discovery NCC-1031 3D Printing Model at Gambody YouTube channel.

Also, you may like USS Enterprise NCC-1701 3D Printing Model and Spock 3D Printing Figurine, as well as other Space Ships 3D Printing Models.

_______

FAQ:

Where can I print a model if I have no printer?

How to get started with 3D printing?

How to set up my 3D printer?

How to choose right 3D model print bed positioning?

How to paint printed figurine?

Average customer rating (5 reviews)

5

Ratings breakdown

Click a star rating to filter reviews

Overall experience

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

To avoid printing issues and achieve the best quality, we highly recommend applying the following settings:

Generic

Below you can find printing recommendations for Cura, Bambu Studio, Simplify3D, Slic3r and PrusaSlicer software.

Disclaimer: The following printing settings are a recommendation, not an obligation. The parameters can vary depending on the peculiarities of your 3D printer, the material you use, and especially the particular assembly part you are working with. Each part that any model comprises often needs preliminary review, and you are free to tweak the settings the way you find suitable.

Note:

You can scale up the model (downscaling for FFF/FDM 3D printers is not recommended!);

All connectors should be printed at 100% Infill.

Bambu Lab printing recommendations:

These basic 3D printing settings recommendations for beginners were tested in Bambu Studio 1.9.1. Test models were printed on the Bambu Lab A1, Bambu Lab A1 Mini, Creality Ender 3 S1, Anycubic Kobra 2, and Anycubic Vyper using PLA and PETG filaments.

To avoid printing problems, we recommend the following settings:download

Cura printing recommendations:

These are averaged settings which were tested in the Cura 5.2.1 slicer. Test models were printed on Anycubic Vyper, Creality Ender 3 Pro with PLA filament.

To avoid printing problems, we recommend the following settings:download

Simplify3D printing recommendations:

These are averaged settings which were tested in the Simplify3D 5.0.0 slicer. Test models were printed on Anycubic Vyper, FLSUN v400, Ender3 S1 with PLA filament.

To avoid printing problems, we recommend the following settings:download

Slic3r printing recommendations:

These basic 3D printing settings recommendations for beginners were tested in Slic3r 1.3.0 software. Test models were printed on Ultimaker 2, Creality Ender 3, Creality Cr-10S pro v2, Anycubic I3 Mega, Anycubic I3 MegaS, Anycubic Vyper with PLA and PetG filaments.

To avoid printing problems, we recommend the following settings:download

PrusaSlicer printing recommendations:

These basic 3D printing settings recommendations for beginners were tested in PrusaSlicer 2.3.1. Test models were printed on Ultimaker 2, Creality Ender 3, Creality Cr-10S pro v2, Anycubic I3 Mega, Anycubic I3 MegaS, Anycubic Vyper with PLA and PETG filaments.

To avoid printing problems, we recommend the following settings:download