Files

3D model format

Stereolithography (.stl)

Total files

Slicer settings

Mesh error check

not specified

Support

Lifetime support from Gambody team

Update requests

not specified

Model versions

FFF/FDM

Assembly method

not specified

Features

DLP/SLA

Assembly method

not specified

Features

FFF/FDM

Assembly method

not specified

Features

DLP/SLA

Assembly method

not specified

Features

Additional details

Part of diorama

No

Special pack included

No

You will get instant access to the STL files of USS Enterprise NCC-1701-E 3D Printing Model | Assembly after completing your purchase. Simply add the model to your cart and check out using PayPal, credit or debit card, Apple Pay, Google Pay, Alipay, or other available payment methods.

Watch the assembly video for USS Enterprise NCC-1701-E 3D Printing Model | Assembly , and explore more tutorials, behind-the-scenes content, 3D printing timelapses, and painting guides on the official Gambody YouTube channel.

This 3D model of USS Enterprise NCC-1701-E inspired by the Star Trek universe consists of files in StereoLithography (.Stl) format that is optimized for 3D printing.

Before printing the files, we strongly recommend reading the PRINTING DETAILS section.

WHAT WILL YOU GET AFTER PURCHASE?

- 4 versions of the NCC-1701-E STL files for FFF/FDM, DLP/SLA 3D printers - files for each version are available for download after the purchase;

- STL files of high-poly Enterprise-E 3D Model for 3D printing consist of 164 parts;

- Sizes:

- FFF/FDM: 59 mm tall, 170 mm wide, 490 mm deep;

- FFF/FDM (on the platform): 121 mm tall, 170 mm wide, 490 mm deep;

- DLP/SLA: 30 mm tall, 85 mm wide, 245 mm deep;

- DLP/SLA (on the platform): 60 mm tall, 85 mm wide, 245 mm deep;

- Assembly Manual for FFF/FDM and DLP/SLA versions in PDF format;

- Detailed settings that we provide as a recommendation for Cura, Simplify3D and Slic3r for the best print- Full technical support from the Gambody Support Team.

Detailed information about this 3D printing figurine is available in the DESCRIPTION section.

Before printing, take a look at Printing Details for recommended settings and tips to achieve better results.

ABOUT THIS 3D MODEL

The graceful NCC-1701-E is the sixth successor of the name “Enterprise” and the pinnacle of the Federation Starfleet ship design and armament configuration. Although longer than previous units seen in Star Trek, its internal space is significantly more compact and hosts a smaller crew dispatched on special missions. The cutting-edge ship is not to be used lightly in battles, but it would be perfect for your collection of 3D prints!

Our contributing 3D artist designed the impressive Enterprise NCC-1701-E in the form of a 3D model for you to recreate its advanced beauty at home. The oblong ship with the swept-back nacelle configuration is illuminated by hundreds of viewports and powerful engines that cut through the fabric of space. The 3D printing model allows you to install lots of LEDs and create an incredibly realistic display of your favourite starship.

ADAPTATION FOR 3D PRINTING

USS Enterprise NCC-1701-E for 3D printing is an static assembly model and its moderation and adaptation for different types of 3D printers took the Gambody team 35 hours in total.

For you to receive the cleanest 3D printing result possible and minimize the amount of filament needed for generated support, the USS Enterprise NCC-1701-E was divided into convenient assembly parts.All assembly parts in the FFF/FDM 1.0 version are provided in STL files in recommended positions that were worked out in order to ensure the smoothness of the details’ surfaces after printing and that the 3D printing beginners won't face difficulties when placing the parts on a build plate. After downloading any model's file you will also receive "Assembly Manual" for FFF/FDM 1.0 and DLP/SLA 1.0 versions in PDF format. We highly recommend that you get acquainted with the “Assembly video” and "Assembly Manual" before getting down to the USS Enterprise NCC-1701-E model.

The model is saved in STL files, a format supported by most 3D printers. All STL files for 3D printing have been checked in Netfabb and no errors were shown.The model’s scale was calculated from the approximate length of the USS Enterprise NCC-1701-E - 685 700 mm. The 3D printing model’s chosen scales are 1/1400 for the FFF/FDM version and 1/1800 for the DLP/SLA version.

VERSIONS' SPECIFICATIONS

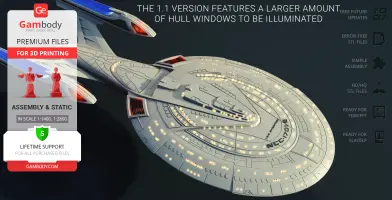

FFF/FDM 1.1 version features:

- Contains 41 parts;

- A printed model is 59 mm tall, 170 mm wide, 490 mm deep;

- A printed model on the platform is 121 mm tall, 170 mm wide, 490 mm deep;

- New hull cutting;

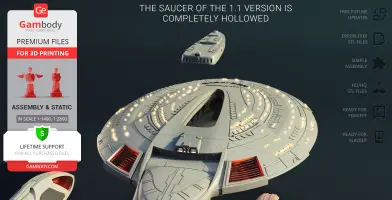

- The saucer of 1.1 version is completely hollowed;

- Larger amount of hull windows to be illuminated;

- All parts are divided in such a way that you will print them with the smallest number of support structures.

DLP/SLA 1.1 version features:

- Contains 39 parts;

- A printed model is 30 mm tall, 85 mm wide, 245 mm deep;

- A printed model on the platform is 60 mm tall, 85 mm wide, 245 mm deep;

- New hull cutting;

- The saucer of 1.1 version is completely hollowed;

- Larger amount of hull windows to be illuminated;

- All parts are divided in such a way to fit the build plates and to ensure that support structures are generated where needed.

FFF/FDM 1.0 version features:

- Contains 48 parts;

- A printed model is 59 mm tall, 170 mm wide, 490 mm deep;

- A printed model on the platform is 121 mm tall, 170 mm wide, 490 mm deep;

- You can choose between parts with raised markings and patterns and clean parts;

- Tunnels for LED wiring to light up the engine ports, nacelle pylons, viewports; the battery can be hidden in the head of the craft;

- Parts titled “new_LED” are custom parts with edited tunnels for LED wiring for 3D printing in larger scales;

- All parts are divided in such a way that you will print them with the smallest number of support structures.

DLP/SLA 1.0 version features:

- Contains 36 parts;

- A printed model is 30 mm tall, 85 mm wide, 245 mm deep;

- A printed model on the platform is 60 mm tall, 85 mm wide, 245 mm deep;

- You can choose between parts with raised markings and patterns and clean parts; the battery can be hidden in the head of the craft;- Tunnels for LED wiring to light up the engine ports, nacelle pylons, viewports;

- All parts are divided in such a way to fit the build plates and to ensure that support structures are generated where needed.

You can get the model of USS Enterprise NCC-1701-E for 3D Printing immediately after the purchase! Just click the green Buy button in the top-right corner of the model’s page. You can pay with PayPal or your credit card.

Watch the tutorial on how to assemble USS Enterprise NCC-1701-E 3D Printing Model at Gambody YouTube channel.

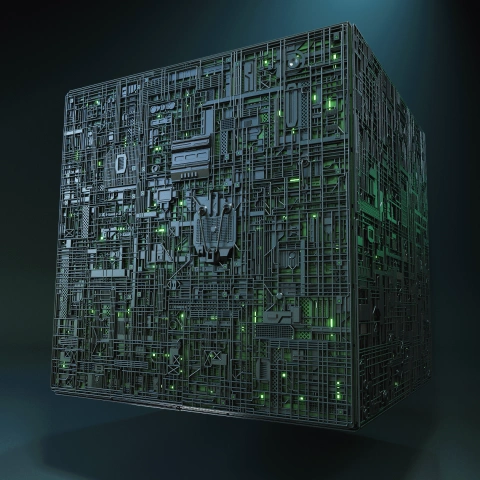

Also, you may like other Star Trek models and Space Ships for 3D Printing.

_______

FAQ:

Average customer rating (15 reviews)

3.9

Ratings breakdown

Click a star rating to filter reviews

Overall experience

Level of detail in the model

3.9

Model cut quality and assembly guide

4

Clarity and accuracy of the model page

3.9

Level of detail in the model

4

Model cut quality and assembly guide

4

Clarity and accuracy of the model page

4

(01_bodyPart_a_Clear_FrontL、02_bodyPart_b_Clear_FrontR_、05_bodyPart_c_Mid_FDM)

Thank you for your thoughtful message and for sharing your idea about adding LED lighting to the USS Enterprise NCC-1701-E 3D Model.

Unfortunately, routing an LED strip in the exact location you described would weaken the structure of the model. For this reason, implementing this specific modification isn’t technically possible without compromising the integrity of the parts.

As an alternative, we recommend using the version specifically designed for LED lighting. The folder with LED-ready parts has now been opened for you. You can find it in the Source Files tab on the model’s page, under “1.0 Alternative version with LEDs,” as shown in the image below.

Please note that while this version uses the same scale, the part segmentation differs from the “1.1 Major modification” version. If you’ve already started printing some parts, we recommend keeping this in mind before proceeding further.

We always do our best to support you and help you achieve the best possible printing and assembly results based on your preferences. We hope this alternative works well for your project, and if you have any further questions or suggestions, please don’t hesitate to reach out — we’re always happy to help.

Level of detail in the model

2

Model cut quality and assembly guide

3

Clarity and accuracy of the model page

0.8

from this https://gambody.zendesk.com/hc/en-us/requests/25789

after that have many star trek ship and so many model come out but still no update of this model ?????? [ i wait and not asking more that hoping you will doing it by not have my comment again and then have nothing update but still have new model out again and agian]

you change webside ui and my comment not show to this page i want the answer and time that you will finish it or if you can't you have to re-fund back to me ? you make me wait for too long and out of patience

And hey… thanks for the 0.5 rating 😂 No hard feelings! I’ll try to earn a better one with the update!

Thank you for your feedback and for taking the time to share your concerns.

First of all, we want to reassure you that your messages and your request for a more studio-accurate update have not been forgotten - neither by our team nor by the author.

Your comments on the model page were not deleted. They are still available in the Comments section. For convenience, here is the direct link to your comment thread:

https://www.gambody.com/premium/uss-enterprise-ncc-1701-e#comment-6709831558

Why this update takes time

In the case of the Enterprise-E, the changes you’re requesting - accurate window geometry, non-mirrored fuselage sections, and full studio-scale detailing - require a complete re-modeling of the ship. This is not a small correction or a quick update, but a full redesign that significantly increases scale, complexity, and production time.

As we’ve explained previously, Enterprise-E (like all models on the Gambody marketplace) is an original STL design created specifically for 3D printing. These models are inspired by iconic ships, but they are not guaranteed to be exact 1:1 reproductions of studio-scale filming miniatures. All promotional materials on the model pages are shown openly before purchase and clearly demonstrate the design as fan art.

The current version of the model remains popular and has received many positive reviews from makers. Your request for a studio-scale version is completely understandable, but it is also a highly specific upgrade and it affects how the author prioritizes future projects. The author has decided to focus on expanding the Star Trek ship lineup for the community, rather than reworking a model that already has strong overall feedback from 3D printing enthusiasts. That’s why, even after some time has passed since your message, this update has not moved forward yet.

What happens next

After internal discussions with the author, Danny Lee, and our Moderation Team, it has been agreed that an updated version of the USS Enterprise NCC-1701-E is planned, with an estimated release window of approximately 2 months. At this stage, we are aiming for an update around March.

We truly appreciate your passion for Star Trek and for high-fidelity models, and we’re sorry this process has tested your patience. We hope you can give all of us a little more time to deliver the update with the level of quality needed to meet your personal accuracy expectations.

Level of detail in the model

4.8

Model cut quality and assembly guide

4.9

Clarity and accuracy of the model page

5

The result looks truly impressive! Great job on the build!

We’d love to see your finished model shared in our Facebook community as well: https://www.facebook.com/groups/183216945475583

Models shared by makers are a real source of inspiration for the 3D printing community — it’s always great to see how a project comes together in the end.

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

4

Model cut quality and assembly guide

4

Clarity and accuracy of the model page

4

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

1

Model cut quality and assembly guide

1

Clarity and accuracy of the model page

1

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

3

Model cut quality and assembly guide

3

Clarity and accuracy of the model page

3

Level of detail in the model

1

Model cut quality and assembly guide

1

Clarity and accuracy of the model page

1

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

4

Model cut quality and assembly guide

4

Clarity and accuracy of the model page

4

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Below you'll find detailed slicing settings for Bambu Studio 2.0+, Orca Slicer 2.0+, UltiMaker Cura 5.0+, PrusaSlicer 2.0+, Slic3r 1.3+, Simplify3D 5.0+ to help you get the best results when printing this model. These settings are optimized specifically for this 3D model, but please note they may need slight adjustments depending on your printer or filament. When in doubt, refer to your printer's user manual.

To avoid printing issues and achieve the best quality, we highly recommend applying the following settings:

For better quality use 0.12 mm layer height, for fast printing use 0.2 mm layer height. For pins and the Ge connectors, use 0.2 layer height.

120-150% of your Layer Height

But you can paint the seam if you want.

You have to calibrate this parameter

You have to calibrate this parameter

You have to calibrate this parameter

For pins and power elements of the structure, such as the vehicle frame, use 3 loop

Disabled for vehicles and enabled for characters

For 0,2 Layer Height

The parameters in this tab vary greatly, it all depends on the quality of your printer. For example, if you have a classic Ender3, stick to the minimum parameters, but if you have a newer printer, for example Anycubic cobra 3 v2, you can select the maximum recommended values

Settings for advanced users, change these parameters only if you have sufficient 3D printing expertise

Enable this parameter if your model requires supports

We also recommend placing and removing supports manually in some places using special button

1-2 loops for more thick support

Top Z distance = 1-1.3 layer Height. If the supports are hard to remove, try increasing this setting by 0.1-0,4 mm

Bottom Z distance = 1-1.3 layer Height. If the supports are hard to remove, try increasing this setting by 0.1-0,4 mm

You have to calibrate this parameter which one is better for your filament

Increase this parameter if the supports are hard to remove from walls

For PLA and PETG filament types

5-8 mm is optional for small prints that have bad adhesion to the build plate

You have to calibrate this parameter

Read the description on your filament roll

Read the description on your filament roll and increase this parameter for fast printers

Read the description on your filament roll and increase this parameter for fast printers

For better quality use 0.12 mm layer height, for fast printing use 0.2 mm layer height. For pins and the Ge connectors, use 0.2 layer height.

120-150% of your Layer Height

But you can paint the seam if you want.

0.01-0.05 You have to calibrate this parameter

0.01-0.05 You have to calibrate this parameter

0.1-0.2 You have to calibrate this parameter

For pins and power elements of the structure, such as the vehicle frame, use 3 loop

Disabled for vehicles and ships, enabled for characters

For 0,2 Layer Height

For 0,2 Layer Height

The parameters in this tab vary greatly, it all depends on the quality of your printer. For example, if you have a classic Ender3, stick to the minimum parameters, but if you have a newer printer, for example, Anycubic Kobra 3 Or Bambulab A1, you can select the maximum recommended values.

Settings for advanced users, change these parameters only if you have sufficient 3D printing expertise

Enable this parameter if your model requires supports

We also recommend placing and removing supports manually in some places using special button

Top Z distance = 1-1.3 layer Height. If the supports are hard to remove, try increasing this setting by 0.1-0,4 mm

Bottom Z distance = 1-1.3 layer Height. If the supports are hard to remove, try increasing this setting by 0.1-0,4 mm

Increase this parameter if the supports are hard to remove from walls

For PLA and PETG filament types

5-8 mm is optional for small prints that have bad adhesion to the build plate

Read the description on your filament roll

Read the description on your filament roll and increase this parameter for fast printers

You have to calibrate this parameter

Read the description on your filament roll and increase this parameter for fast printers

Read the description on your filament roll

This field is filled in according to your printer specifications when you add it to the slicer.

You can add custom G-code here for the start and end of the print. However, be careful - this is for advanced users only!

You have to calibrate your printer using Ge retraction test models

Retraction Length: For direct-drive setups use 0.5 mm to 2.5 mm; for Bowden extruders use 5 to 7 mm

This is how fast the filament is pulled back—40-60 mm/s for direct drive and 30-50 mm/s for Bowden setups.

You have to calibrate this parameter: Reduce it until the printer starts to hit the parts with the nozzle during printing, then increase it by 0.2.

For better quality use 0.12 mm layer height, for fast printing use 0.2 mm layer height. For pins and the Ge connectors, use 0.2 layer height.

120-150% of your Layer Height

To increase the strength of the print parts, use wall line count: 3

For pins and connectors use 50% Infill

These parameters are for standard PLA plastic. If you are using a different type of plastic, check the printing temperature recommended by the manufacturer. Also, read the description on your filament spool. For fast printers, add +30 °C to the current parameters.

The parameters in this tab vary greatly, it all depends on the quality of your printer. For example, if you have a classic Ender3, stick to the minimum parameters, but if you have a newer printer, for example Anycubic cobra 3 v3, you can select the maximum recommended values

Settings for advanced users, change these parameters only if you have sufficient 3D printing expertise.

You need to calibrate this parameter using Gambody test models. These values are average values for a Direct Drive extruder; for a Bowden extruder, the values should be increased.

You need to calibrate this parameter using Gambody test models. These values are average values for a Direct Drive extruder; for a Bowden extruder, the values should be increased.

Use this value other than 0 if your nozzle catches on the internal infill during travel moves. Try to keep this value as low as possible in height.

Use normal supports to support large, straight surfaces (most mechanical or technical parts).

You have to calibrate this parameter according to the capabilities of your printer and your filament, using a Gambody test models.

Use 1 instead of 0 if your supports are thin and tall. They will be harder to remove, but much stronger.

Top Z distance = 1-1.3 layer Height. If the supports are hard to remove, try increasing this setting by 0.1-0,4 mm

Increase this parameter if the supports are hard to remove from walls

Use tree supports to support complex objects, such as characters.

You have to calibrate this parameter according to the capabilities of your printer and your filament, using a Gambody test models.

Top Z distance = 1-1.3 layer Height. If the supports are hard to remove, try increasing this setting by 0.1-0,4 mm

Increase this parameter if the supports are hard to remove from walls

Use a skirt for all parts when printing on outdated printers.

Use a brim when printing thin but tall parts, as well as parts with a small bed adhesion area.

For better quality use 0.12 mm layer height, for fast printing use 0.2 mm layer height. For pins and the Ge connectors, use 0.2 layer height.

120-150% of your Layer Height

for 0.2 Layer Height

But you can paint the seam if you want.

(for PLA and PETG)

(5-8 mm is optional for small prints that have bad adhesion to the build plate)

Enable this parameter if your model requires supports

(45-50 degree)You have to calibrate this parameter according to the capabilities of your printer

and your filament, using a Gambody test models.

Top contact Z distance = 1-1.3 layer Height. If the supports are hard to remove, try

increasing this setting by 0.1-0,4 mm

Top contact Z distance = 1-1.3 layer Height. If the supports are hard to remove, try

increasing this setting by 0.1-0,4 mm

Increase this parameter if the supports are hard to remove from walls

The parameters in this tab vary greatly, it all depends on the quality of your printer. For example, if you have a classic Ender3, stick to the minimum parameters, but if you have a newer printer, for example Anycubic cobra 3 v3, you can select the maximum recommended values

Settings for advanced users, change these parameters only if you have sufficient 3D printing expertise. Use the minimum value for outdated printers without acceleration calibration, and the maximum value for modern printers if you need it.

These settings only work for 3D printers with multiple extruders

You can try setting all parameters in this section, except the First layer, to values between 0.75% of your nozzle diameter and 1.25% of your nozzle diameter. Adjusting them will help you work out the optimal parameters for the best quality for your print. As for the First layer, you can set it to 150% of the diameter of your nozzle for better adhesion to the build plate (for a nozzle with a diameter of 0.4 mm, the First layer extrusion width can be from 0.3 mm to 0.5 mm)

For better printing quality you have to calibrate this parameter using Gambody test model.

Check your filament manufacturer's temperature recommendations on the spool.

Cooling parameters depends on the material you use for printing.

*for PLA

For better quality use 0.12 mm layer height, for fast printing use 0.2 mm layer height. For pins and the Ge connectors, use 0.2 layer height.

120-150% of your Layer Height

For 0.12 Layer Height

For 0.12 Layer Height

For pins and connectors use 50% Infill

Use skirt for outdated 3d printers

(5-8 mm is optional for small prints that have bad adhesion to the build plate)

Enable this parameter if your model requires supports

(45-60 degree)You have to calibrate this parameter according to the capabilities of your printer and your filament, using a Gambody test models

Contact Z distance = 1-1.3 layer Height. If the supports are hard to remove, try increasing this setting by 0.1-0,4 mm

The parameters in this tab vary greatly, it all depends on the quality of your printer. For example, if you have a classic Ender3, stick to the minimum parameters, but if you have a newer printer, for example Anycubic cobra 3 v3, you can select the maximum recommended values

Settings for advanced users, change these parameters only if you have sufficient 3D printing expertise. Use the minimum value for outdated printers without acceleration calibration, and the maximum value for modern printers if you need it.

You have to calibrate this parameter from 0.9 to 1.1 according to the capabilities of your printer and your filament, using a Gambody test models.

Check your filament manufacturer's temperature recommendations on the spool.

Cooling parameters depends on the material you use for printing.

Calibrate this value if you need to reduce or improve the adhesion between the plastic and the heat bed

Your current nozzle diameter

You need to calibrate this parameter using Gambody test models. These values are average values for a Direct Drive extruder; for a Bowden extruder, the values should be increased.

Your current nozzle diameter

You have to calibrate this parameter using Gambody test models.

You need to calibrate this parameter using Gambody test models. These values are average values for a Direct Drive extruder; for a Bowden extruder, the values should be increased.

For better quality use 0.12 mm layer height, for fast printing use 0.2 mm layer height. For pins and the Ge connectors, use 0.2 layer height.

For 0,2 Layer Height

For 0,2 Layer Height

To increase the strength of the print parts, use Outline Perimeters: 3

You can enable this parameter to print rounded or spherical models, as well as character models.

Use this option only if your parts are too tight. but better calibrate your printer extrusion

Use this option only if your parts are too tight. but better calibrate your printer extrusion

Use 2 and more if you want to create skirt instead brim

1-2 for skirt and 10-20 for brim

Use for wipe nozzle if you need

Use For ABS filament

For pins and connectors use 50% Infill

Top Z distance = 1-1.3 layer Height. If the supports are hard to remove, try increasing this setting by 0.1-0,4 mm

Calibrate your filament and detect optimal temperature for it

Average temperature for PLA filament

The parameters in this tab vary greatly, it all depends on the quality of your printer. For example, if you have a classic Ender3, stick to the minimum parameters, but if you have a newer printer, for example Anycubic cobra 3 v3, you can select the maximum recommended values

Settings for advanced users, change these parameters only if you have sufficient 3D printing expertise.